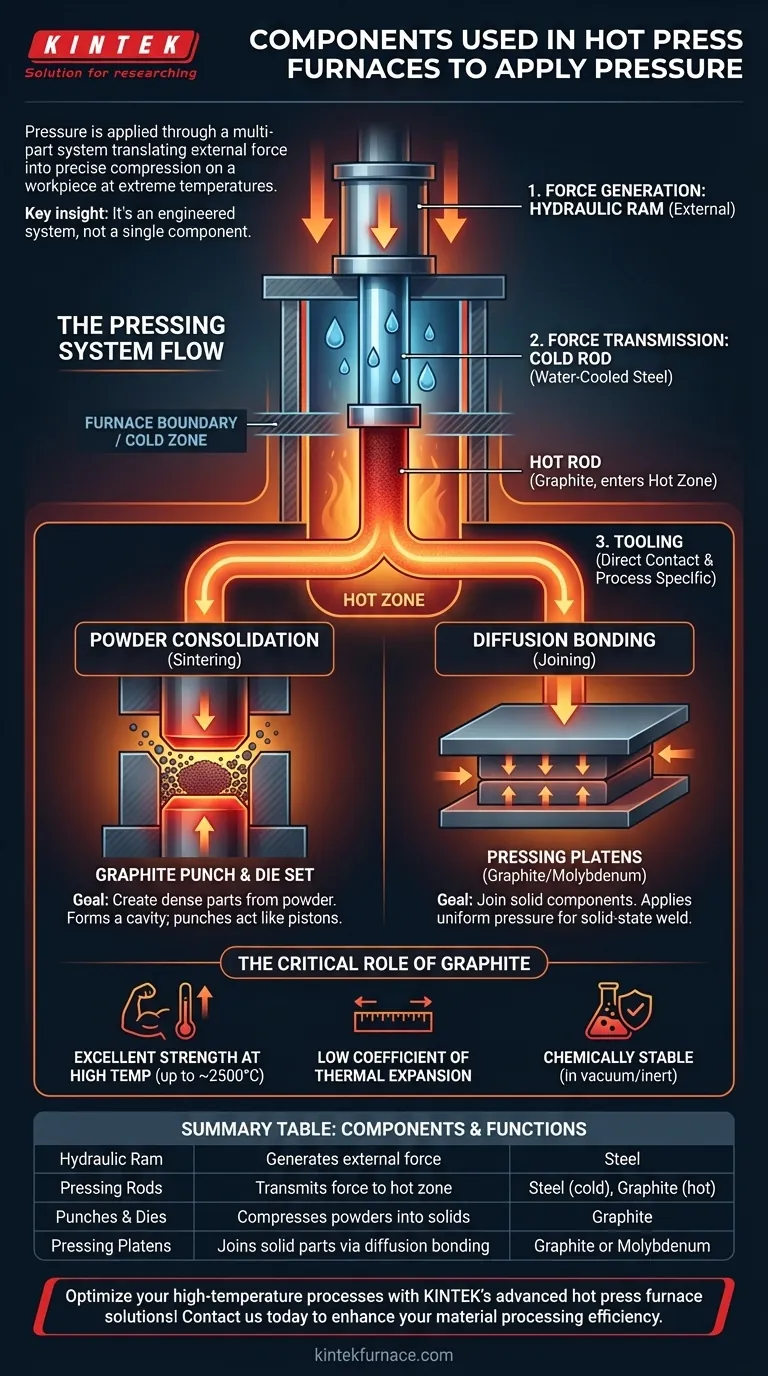

In a hot press furnace, pressure is applied through a multi-part system that translates external force into precise compression on a workpiece at extreme temperatures. This system primarily consists of pressing rods (both hot and cold), which connect an external press to internal tooling, and specialized tooling like graphite punches, dies, or platens that make direct contact with the material being processed.

The key insight is that pressure application in a hot press is not about a single component, but a carefully engineered system. The choice of components, particularly the tooling, is entirely dictated by the specific material processing goal, such as consolidating powder or bonding solid parts.

The Core Components of the Pressing System

A hot press furnace is part of a larger press frame, typically driven by hydraulics. The components inside the furnace are designed to transfer this force while withstanding immense heat and vacuum or inert atmospheres.

The Force Generation: Hydraulic Rams

The initial force does not originate inside the furnace. It is generated externally by a hydraulic ram that is part of the larger press structure. This ram provides the powerful, controlled force measured in tons.

The Force Transmission: Pressing Rods

Pressing rods act as the bridge between the external ram and the internal tooling. They must transfer force accurately along a single axis.

These are commonly a two-part system: a "cold" rod outside the hot zone (usually water-cooled steel) pushes on a "hot" rod made of a high-temperature material like graphite that can enter the furnace's hot zone.

The Tooling for Powder Consolidation: Punches and Dies

When the goal is to turn powders into a solid part (a process called sintering), a graphite punch and die set is used.

The die forms a cavity or mold to contain the powder. One or more punches act like pistons, compressing the powder within the die at high temperature and pressure until it densifies into a solid component.

The Tooling for Diffusion Bonding: Pressing Platens

For diffusion bonding, where two or more solid parts are joined together, pressing platens are used.

These are flat, rigid plates, often made of graphite or molybdenum. The workpieces are placed between the platens, which apply uniform pressure across their surfaces, forcing the atoms at the interface to inter-diffuse and form a solid-state weld.

Understanding the Trade-offs

The design of the pressing system involves critical trade-offs between thermal management, material compatibility, and mechanical stability. The most important distinction is how force is transmitted into the hot zone.

The Standard 'Cold Rod' Design

Most hot presses use an external, water-cooled metal rod that pushes on an internal graphite rod or push-stack.

This design effectively isolates the main hydraulic press frame and its sensitive components from the extreme temperatures of the furnace hot zone, ensuring longevity and safety. The primary challenge is maintaining perfect alignment between the rods.

The Critical Role of Graphite

Graphite is the dominant material for internal hot press components like hot rods, punches, and dies for several key reasons.

It exhibits excellent strength at high temperatures (it gets stronger up to ~2500°C), has a very low coefficient of thermal expansion, and is chemically stable in vacuum or inert environments. It is also easily machined into complex tool shapes.

Making the Right Choice for Your Goal

Selecting the correct pressure components is fundamental to achieving your desired material properties. Your process dictates your tooling.

- If your primary focus is creating dense parts from powder: Your critical components will be a precision-machined graphite punch and die set.

- If your primary focus is joining solid components: You must use a set of flat, uniform pressing platens to ensure even pressure distribution.

- If your primary focus is process reliability and safety: The standard two-part system of an external "cold" rod and an internal "hot" graphite rod assembly is the most proven and robust design.

Understanding this system allows you to control the critical variables of temperature and pressure with precision.

Summary Table:

| Component | Function | Common Material |

|---|---|---|

| Hydraulic Ram | Generates external force | Steel |

| Pressing Rods | Transmits force to hot zone | Steel (cold), Graphite (hot) |

| Punches and Dies | Compresses powders into solids | Graphite |

| Pressing Platens | Joins solid parts via diffusion bonding | Graphite or Molybdenum |

Optimize your high-temperature processes with KINTEK's advanced hot press furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your material processing efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density