At its core, the difference between Hot Pressing and Hot Isostatic Pressing (HIP) lies in the direction of the applied force. Hot Pressing uses a single-axis, directional pressure from a mechanical press, while HIP uses uniform, gas-based pressure applied equally from all directions. This fundamental distinction dictates the capabilities, costs, and ideal applications for each process.

The choice is a direct trade-off between manufacturing simplicity and ultimate material performance. Hot Pressing is a cost-effective workhorse for simple shapes, whereas HIP is a premium process for creating complex, fully dense components where failure is not an option.

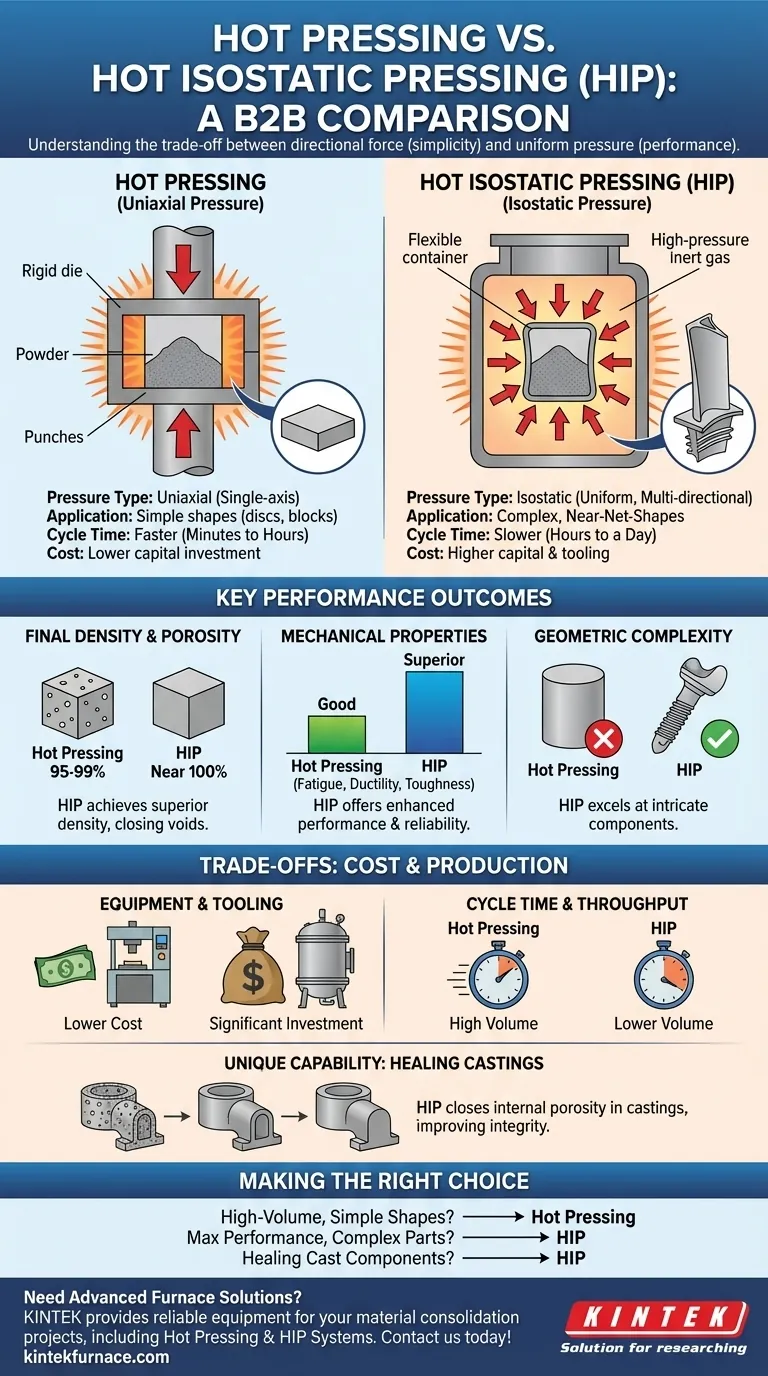

The Fundamental Difference: Uniaxial vs. Isostatic Pressure

To understand when to use each method, you must first visualize how they consolidate material powders. Both use high temperature to make the material pliable, but the way they apply pressure is completely different.

How Hot Pressing Works

Hot Pressing involves placing a powder into a rigid die, which is then compressed by one or two moving punches along a single vertical axis. The entire die and powder assembly is heated simultaneously.

This uniaxial pressure is highly effective for consolidating powders into simple geometries like discs, blocks, or cylinders. It is a direct, mechanical action.

How Hot Isostatic Pressing (HIP) Works

In Hot Isostatic Pressing, the powder is first sealed in a flexible or form-fitting container, often made of metal. This container is then placed inside a high-pressure vessel.

The vessel is filled with a high-pressure inert gas (like argon) and heated. This isostatic pressure acts on the container uniformly from all sides, consolidating the powder into a fully dense, solid part. The pressure is transmitted hydrostatically, eliminating die-wall friction.

Comparing Key Performance Outcomes

The difference in pressure application leads to significant variations in the final part's quality, properties, and geometric possibilities.

Final Density and Porosity

HIP is the industry standard for achieving near 100% theoretical density. Because pressure is applied from all directions, it effectively closes all internal voids and porosity within the material.

Hot Pressing achieves high densities (often 95-99%), but residual porosity can remain. Friction between the powder and the die walls can create pressure gradients, making it harder to densify the material's corners and edges uniformly.

Mechanical Properties

The superior density from HIP directly translates to superior mechanical properties. By eliminating internal pores, which act as stress concentrators and crack initiation sites, HIP significantly improves a material's fatigue life, ductility, and fracture toughness.

This makes HIP essential for mission-critical components in aerospace, medical, and energy applications where material failure would be catastrophic.

Geometric Complexity

Hot Pressing is limited to simple, prismatic shapes that can be easily ejected from a rigid die.

HIP excels at producing complex, near-net-shape parts. Since the pressure is applied by a gas, it conforms perfectly to intricate geometries, such as turbine blades or orthopedic implants, minimizing the need for extensive post-process machining.

Understanding the Trade-offs: Cost and Production

While HIP offers superior technical performance, it comes at a significant cost in both equipment and cycle time.

Equipment and Tooling Costs

The primary cost of HIP is the high-pressure vessel itself, which represents a massive capital investment. Hot pressing equipment is generally less expensive and more common.

Furthermore, most HIP processes require the powder to be encapsulated in a disposable metal "can," which must be produced and later removed, adding cost and complexity to the workflow.

Cycle Time and Throughput

Hot pressing cycles are typically measured in minutes to a few hours, allowing for relatively high throughput for standard parts.

HIP cycles are significantly longer, often lasting many hours or even a full day. This is due to the time required to safely heat, pressurize, hold, and cool the large vessel, making it a much lower-volume process.

A Unique Capability: Healing Castings

Beyond consolidating powders, HIP has a unique ability to "heal" defects in parts made by other methods, like casting. By subjecting a cast component to the HIP cycle, internal gas porosity and voids can be closed, dramatically improving the casting's structural integrity.

Making the Right Choice for Your Application

Selecting the correct process requires a clear understanding of your project's non-negotiable requirements.

- If your primary focus is high-volume production of simple shapes: Hot pressing is the clear choice for its lower cost, faster cycle times, and sufficient densification for many applications like sputtering targets or basic ceramic armor plates.

- If your primary focus is maximum performance and reliability in complex parts: HIP is the only viable option for creating fully dense, near-net-shape components for critical applications like jet engine disks or medical implants.

- If your primary focus is improving the integrity of existing cast components: HIP is uniquely suited as a post-processing step to heal internal porosity and upgrade the performance of high-value castings.

Understanding this balance between directional force and uniform pressure is the key to mastering advanced material consolidation.

Summary Table:

| Aspect | Hot Pressing | Hot Isostatic Pressing (HIP) |

|---|---|---|

| Pressure Type | Uniaxial (single-axis) | Isostatic (uniform from all directions) |

| Final Density | 95-99% theoretical | Near 100% theoretical |

| Geometric Complexity | Simple shapes (e.g., discs, blocks) | Complex, near-net-shapes (e.g., turbine blades) |

| Mechanical Properties | Good, with some porosity | Superior fatigue life, ductility, toughness |

| Cost | Lower equipment and tooling costs | Higher capital investment and disposable can costs |

| Cycle Time | Minutes to hours (faster) | Hours to a day (slower) |

| Unique Capabilities | Cost-effective for high-volume simple parts | Heals defects in castings, ideal for critical applications |

Need advanced high-temperature furnace solutions for your material consolidation projects? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements for hot pressing, HIP, and more. Contact us today to enhance your lab's performance and achieve superior results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing