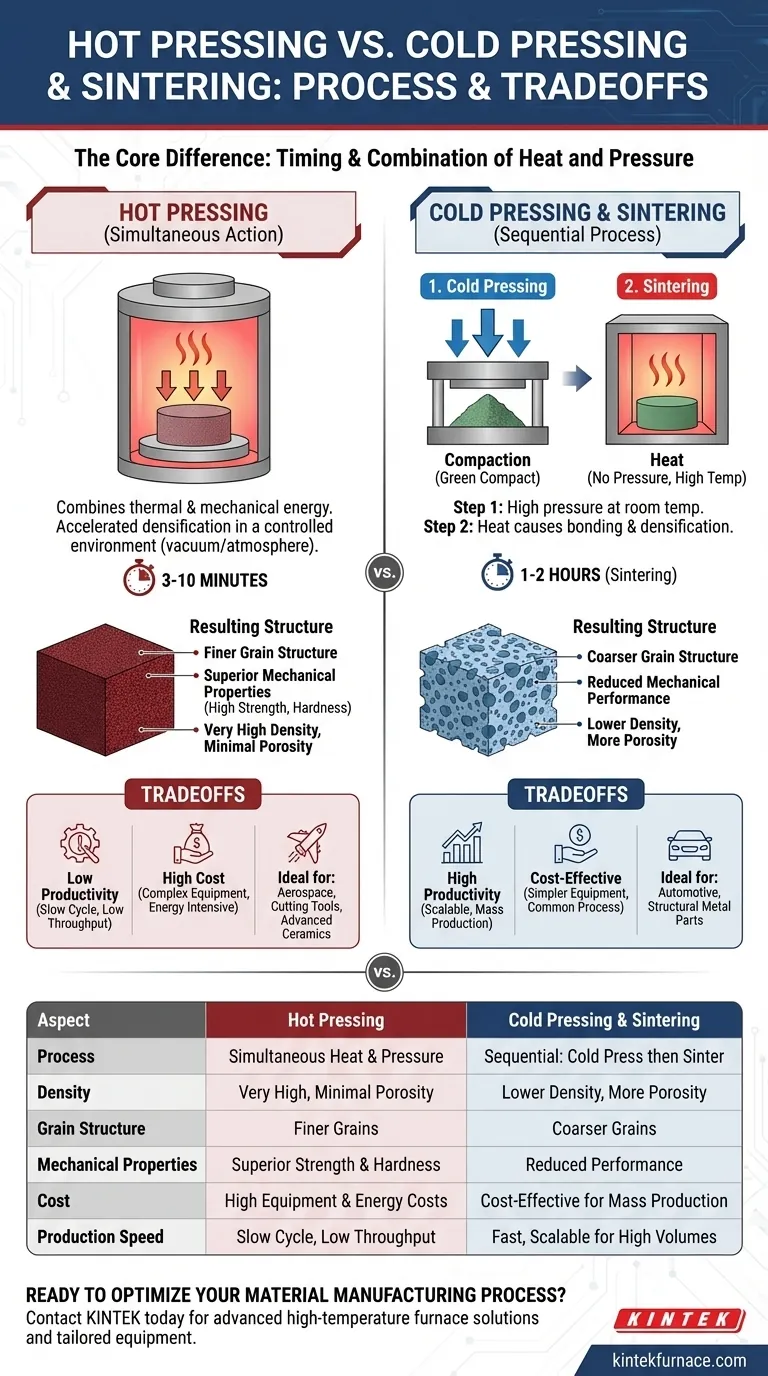

At its core, the difference between hot pressing and the conventional method of cold pressing and sintering lies in the timing and combination of heat and pressure. Hot pressing applies thermal and mechanical energy simultaneously to densify a material, whereas the conventional method is a sequential, two-step process: first compacting the material at room temperature (cold pressing), then heating it without pressure (sintering).

Choosing between these methods is a classic engineering trade-off. Hot pressing prioritizes final material performance and density at the expense of cost and production speed, while cold pressing and sintering prioritizes cost-effectiveness and scalability for mass production.

The Fundamental Process Difference

To understand the downstream effects on cost and quality, we must first examine how the two processes are mechanically different.

Hot Pressing: A Combined Action

Hot pressing is an activated sintering process where a powder compact is heated and pressed at the same time, typically inside a vacuum or controlled atmosphere.

This simultaneous action uses both thermal and mechanical energy to force the material's particles together, significantly accelerating densification.

Cold Pressing & Sintering: A Two-Step Method

This is a more traditional powder metallurgy route. First, the powder is compacted into a desired shape (a "green compact") using high pressure at room temperature.

In the second, separate step, this green compact is placed in a furnace and heated to a high temperature below its melting point. The heat alone causes the particles to bond and the part to densify.

Impact on Material Properties and Microstructure

The process you choose directly dictates the final characteristics of the component, from its internal structure to its mechanical strength.

Grain Structure and Strength

Hot pressing generally produces materials with a finer grain structure. The simultaneous application of pressure physically inhibits the natural tendency of grains to grow larger at high temperatures.

Finer grains typically lead to superior mechanical properties, such as higher strength and hardness.

In contrast, the high temperatures and longer times required for conventional sintering often result in coarser grain structures, which can reduce the material's overall mechanical performance.

Final Density

Because pressure is actively applied during the heating phase, hot pressing is extremely effective at closing internal pores.

This results in parts with very high density and minimal porosity, which is critical for high-performance applications. Vacuum hot pressing further enhances this by removing trapped gases.

Process Speed and Equilibrium

Hot pressing achieves densification much faster, often in 3-10 minutes compared to the 1-2 hours required for conventional sintering.

However, this speed means the process is often unbalanced. There may not be enough time for the material's phases to reach full chemical equilibrium, which can result in a unique microstructure compared to a slowly sintered part.

Understanding the Trade-offs: Cost, Speed, and Scale

The superior properties achieved through hot pressing come with significant practical and economic trade-offs.

Productivity and Throughput

While the densification phase of hot pressing is rapid, the overall process has low productivity. Each cycle requires heating and cooling a large press and die assembly, which is time-consuming.

Cold pressing and sintering, with its separate steps, allows for continuous processing. Parts can be pressed quickly one after another and then loaded into a furnace in large batches, making it ideal for mass production.

Equipment and Energy Costs

Hot pressing equipment is complex and expensive. It must withstand extreme temperatures and pressures simultaneously, requiring specialized materials and sophisticated controls. The process is also very energy-intensive.

Cold presses and sintering furnaces are simpler, more common, and generally less expensive to purchase and operate, resulting in a more cost-effective process for large volumes.

Making the Right Choice for Your Application

Your decision must be guided by the non-negotiable requirements of your project.

- If your primary focus is maximum performance and density: Hot pressing is the clear choice for applications like aerospace components, cutting tools, or advanced ceramics where material properties are paramount.

- If your primary focus is cost-effectiveness and high-volume production: Cold pressing and sintering is the industry standard for producing parts like automotive components and structural metal pieces at scale.

- If your primary focus is creating a novel material with a unique microstructure: Hot pressing can be a valuable tool, as its non-equilibrium nature can produce phases and structures not achievable through slower methods.

Understanding this fundamental trade-off between ultimate performance and production scalability empowers you to select the precise manufacturing path for your specific goal.

Summary Table:

| Aspect | Hot Pressing | Cold Pressing & Sintering |

|---|---|---|

| Process | Simultaneous heat and pressure | Sequential: cold press then sinter |

| Density | Very high, minimal porosity | Lower density, more porosity |

| Grain Structure | Finer grains | Coarser grains |

| Mechanical Properties | Superior strength and hardness | Reduced performance |

| Cost | High equipment and energy costs | Cost-effective for mass production |

| Production Speed | Slow cycle, low throughput | Fast, scalable for high volumes |

| Ideal Applications | Aerospace, cutting tools, advanced ceramics | Automotive, structural metal parts |

Ready to optimize your material manufacturing process? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need high-performance hot pressing or scalable sintering solutions, we deliver tailored equipment to enhance your lab's efficiency and outcomes. Contact us today to discuss how we can support your specific application!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity