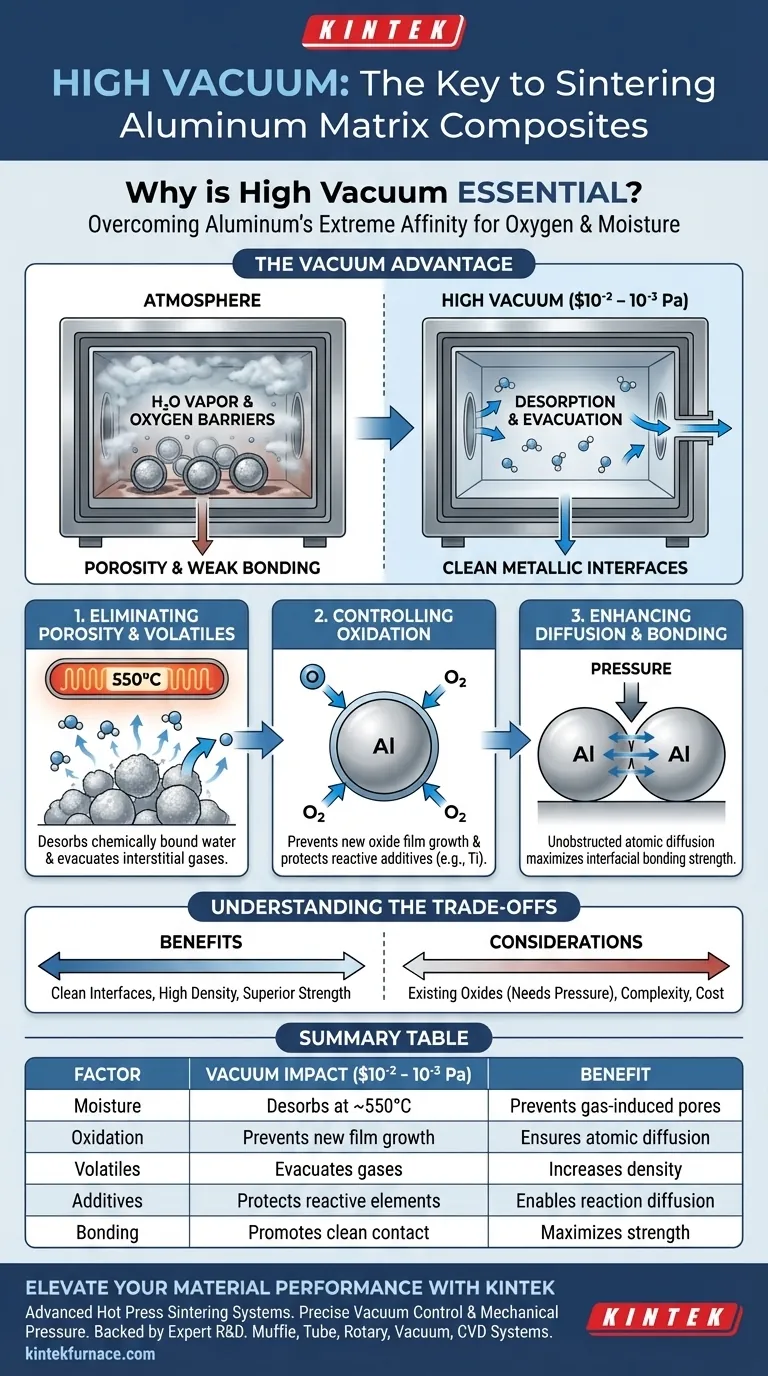

A high vacuum environment is technically mandatory in the hot press sintering of aluminum matrix composites due to aluminum’s extreme affinity for oxygen and moisture. Its primary function is to actively desorb chemically bound water vapor at temperatures around 550°C and prevent the formation of oxide barriers, thereby enabling the atomic diffusion necessary for a dense, high-strength material.

The Core Insight Aluminum powder inherently possesses a tenacious oxide layer and adsorbs moisture, both of which act as barriers to sintering. The vacuum environment is not merely for cleanliness; it is an active processing tool that strips away these volatile impediments to allow for direct metallic bonding and unobstructed reaction diffusion.

Eliminating Porosity and Volatiles

Desorption of Chemically Adsorbed Water

Aluminum powder surfaces are highly prone to adsorbing water vapor from the atmosphere.

During the heating process, particularly around 550°C, a high vacuum system effectively promotes the desorption and exhaust of this chemically adsorbed water. Removing this moisture before the sintering phase is critical to prevent the formation of gas-induced pores in the final composite.

Evacuation of Interstitial Gases

Beyond surface moisture, gas is often trapped in the interstitial spaces between powder particles.

The vacuum environment effectively evacuates these trapped gases and removes volatiles released during heating. By clearing these interstitial spaces, the process minimizes porosity defects and ensures a higher density in the final sintered body.

Controlling Oxidation and Interface Quality

Prevention of Oxide Film Growth

Aluminum reacts rapidly with oxygen at high temperatures to form a stable oxide film.

Maintaining a high vacuum (often in the range of $1 \times 10^{-2}$ Pa to $10^{-3}$ Pa) cuts off the oxygen supply, effectively preventing further oxidation of the aluminum matrix. This is essential because oxide films act as thermal and diffusion barriers that degrade the material's performance.

Protecting Reactive Alloying Elements

Many aluminum matrix composites incorporate reactive additives, such as titanium powder.

The vacuum environment protects these highly reactive elements from oxidation at elevated temperatures. Preserving the metallic state of these additives ensures they can participate in effective reaction diffusion with the aluminum matrix, rather than becoming inert oxides.

Enhancing Diffusion and Bonding

Unobstructed Atomic Diffusion

For sintering to occur, atoms must diffuse across particle boundaries.

By preventing the formation of thick oxide films, the vacuum ensures a clean contact interface between layers (such as amorphous alloy layers and aluminum). This creates unobstructed channels for elemental diffusion, which is the mechanism that actually bonds the material together.

Maximizing Interfacial Bonding Strength

The integrity of the composite relies on the strength of the bond between the matrix and the reinforcement (e.g., diamond or titanium).

A purified vacuum environment promotes direct metallic bonding between particles. This results in high-quality metallurgical bonds, significantly enhancing the mechanical properties and thermal conductivity of the composite.

Understanding the Trade-offs

While high vacuum is essential, relying on it effectively requires understanding its limitations.

Vacuum vs. Existing Oxides

Vacuum is excellent at preventing new oxidation and removing volatiles, but it cannot easily remove stable, pre-existing aluminum oxide skins.

To overcome the oxide films that already exist on the powder, mechanical pressure (e.g., 30 MPa) is often required alongside the vacuum. The pressure physically ruptures the oxide shell, allowing the clean metal underneath—preserved by the vacuum—to bond.

Complexity and Cost

Maintaining high vacuum levels (e.g., $10^{-3}$ Pa) requires sophisticated sealing and pumping systems.

This increases the complexity of the equipment and the processing time. However, for high-performance applications where thermal conductivity and mechanical strength are paramount, this trade-off is unavoidable.

Making the Right Choice for Your Goal

When configuring your sintering process, align your vacuum protocols with your specific material requirements:

- If your primary focus is mechanical strength: Prioritize high vacuum combined with mechanical pressure to rupture oxide films and maximize particle-to-particle metallic bonding.

- If your primary focus is thermal conductivity: Ensure extreme vacuum levels to maintain clean interfaces between the aluminum and reinforcements (like diamond), as oxides act as thermal insulators.

- If your primary focus is complex alloying (e.g., Al-Ti): Rigidly control the vacuum to prevent the oxidation of reactive additives, ensuring they remain active for reaction diffusion.

Ultimately, the vacuum system is the gatekeeper of interface quality, determining whether your composite becomes a unified solid or a collection of weakly bonded particles.

Summary Table:

| Factor | Impact of High Vacuum ($10^{-2}$ to $10^{-3}$ Pa) | Benefit to Composite |

|---|---|---|

| Moisture | Desorbs chemically bound water at ~550°C | Prevents gas-induced pores |

| Oxidation | Prevents new oxide film growth on Al matrix | Ensures unobstructed atomic diffusion |

| Volatiles | Evacuates interstitial gases & contaminants | Increases final material density |

| Additives | Protects reactive elements like Ti from oxidation | Enables effective reaction diffusion |

| Bonding | Promotes clean metal-to-metal contact | Maximizes interfacial bonding strength |

Elevate Your Material Performance with KINTEK

Don't let oxide barriers and porosity compromise your aluminum matrix composites. KINTEK’s advanced hot press sintering systems provide the precise high-vacuum control ($10^{-3}$ Pa) and mechanical pressure required to achieve superior metallurgical bonding.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for your unique lab and production needs.

Contact KINTEK today to optimize your sintering process!

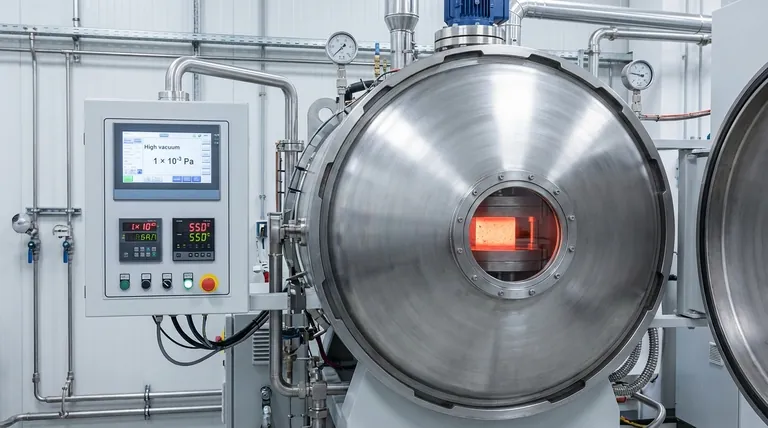

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a high-temperature vacuum pressing furnace play in lithium disilicate fabrication? Expert Insights

- Why is it necessary to treat graphite molds containing mixed powders in a vacuum drying oven before vacuum hot press sintering? Prevent Porosity and Ensure Maximum Density

- How does a vacuum hot pressing furnace contribute to high-hardness composites? Achieve Near-Theoretical Density

- How does vacuum hot pressing equipment enhance the matrix quality of diamond tools through improved wettability? Unlock Superior Diamond Retention

- What advantages does a vacuum press offer in material processing? Achieve Superior Density and Purity

- Why is a hot pressing furnace equipped with a vacuum system necessary for sintering high-entropy alloy coatings? Ensure Purity, Density, and Superior Performance

- What are the technical advantages of Spark Plasma Sintering (SPS) systems? Faster Densification and Superior Strength

- What role does 30 MPa pressure play in SiC/Cu-Al2O3 sintering? Achieve 97.6% Density with Vacuum Hot Pressing