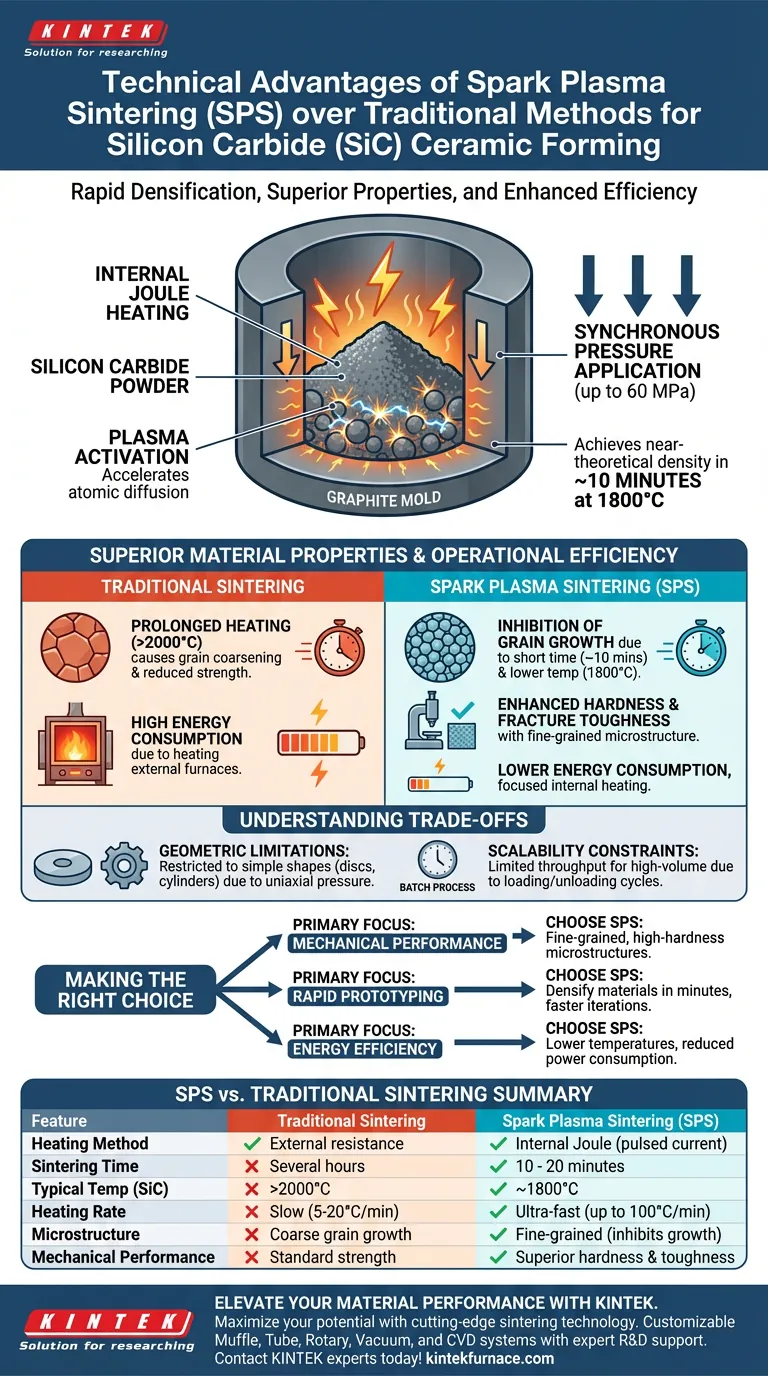

Spark Plasma Sintering (SPS) systems fundamentally outperform traditional silicon carbide forming methods by utilizing pulsed electric current combined with simultaneous axial pressure. This internal heating mechanism allows silicon carbide to reach full densification at 1800°C in as little as 10 minutes, a timeframe unattainable by conventional resistance furnaces.

Core Takeaway Traditional sintering often requires prolonged heating which leads to grain coarsening and reduced mechanical strength. SPS solves this by generating heat directly within the mold and material, achieving near-theoretical density in minutes while preserving a fine-grained, high-strength microstructure.

The Mechanism of Rapid Densification

Internal Joule Heating

Unlike traditional methods that rely on external heating elements, SPS generates heat internally through Joule heating.

Pulsed electric current is passed directly through the graphite mold and the silicon carbide powder. This results in extremely high heating rates, often reaching 100°C per minute.

Plasma Activation

The pulsed current does more than just heat; it creates a plasma activation effect between powder particles.

This accelerates atomic diffusion and promotes grain boundary diffusion, allowing for rapid material consolidation.

Synchronous Pressure Application

SPS systems apply substantial axial pressure, typically up to 60 MPa, simultaneously with the heating cycle.

This mechanical force physically aids in the rearrangement of particles, further reducing the temperature and time required to close pores and achieve full density.

Superior Material Properties

Inhibition of Grain Growth

One of the critical challenges in sintering silicon carbide is controlling grain size; prolonged exposure to high heat typically causes grains to enlarge (coarsen), which weakens the material.

Because SPS completes the sintering process in a very short holding time (often around 10 minutes), it effectively inhibits abnormal grain growth.

Enhanced Hardness and Strength

The result of this rapid, low-temperature process is a bulk ceramic with a fine-grained microstructure.

This structural refinement directly translates to superior physical properties, specifically higher hardness and fracture toughness compared to pressureless sintered silicon carbide.

Operational Efficiency

Lower Processing Temperatures

Traditional silicon carbide sintering often requires temperatures exceeding 2000°C.

SPS achieves full densification at significantly lower temperatures, specifically around 1800°C for silicon carbide.

Energy Consumption

The combination of reduced processing time and lower operating temperatures results in significantly reduced energy consumption.

By eliminating the need to heat a large external furnace chamber, energy is directed solely where it is needed: the mold and the sample.

Understanding the Trade-offs

Geometric Limitations

The SPS process relies on applying uniaxial pressure through graphite molds.

This setup typically restricts the geometry of the final part to simple shapes like discs, cylinders, or plates. Creating complex, net-shape components often requires significant post-processing or is not feasible compared to slip casting or injection molding.

Scalability Constraints

SPS is primarily a batch process.

While the cycle time is short (minutes vs. hours), the need to load and unload graphite dies for every single cycle can limit throughput for high-volume mass production compared to continuous sintering furnaces.

Making the Right Choice for Your Goal

If you are evaluating whether to integrate Spark Plasma Sintering into your production line, consider your specific end-goals:

- If your primary focus is mechanical performance: Choose SPS for its ability to produce fine-grained, high-hardness microstructures that are difficult to achieve with pressureless sintering.

- If your primary focus is rapid prototyping: Choose SPS for its capability to densify materials in minutes rather than hours, allowing for faster iteration cycles.

- If your primary focus is energy efficiency: Choose SPS to utilize lower sintering temperatures (1800°C) and reduce overall power consumption.

SPS converts the sintering process from a thermal endurance test into a precise, rapid electro-mechanical operation.

Summary Table:

| Feature | Traditional Sintering | Spark Plasma Sintering (SPS) |

|---|---|---|

| Heating Method | External resistance heating | Internal Joule heating (pulsed current) |

| Sintering Time | Several hours | 10 - 20 minutes |

| Typical Temp (SiC) | >2000°C | ~1800°C |

| Heating Rate | Slow (5-20°C/min) | Ultra-fast (up to 100°C/min) |

| Microstructure | Coarse grain growth | Fine-grained (inhibits growth) |

| Mechanical Performance | Standard strength/hardness | Superior hardness and toughness |

Elevate Your Material Performance with KINTEK

Maximize your laboratory's potential with cutting-edge sintering technology. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized sintering solutions tailored to your unique research and production needs.

Why partner with KINTEK?

- Customizable Systems: Precision-engineered furnaces designed for your specific material requirements.

- Expert Support: Deep technical expertise to help you optimize densification and microstructure.

- Efficiency: Lower your energy footprint while achieving superior mechanical results.

Ready to transform your ceramic forming process? Contact our technical experts today to find the perfect high-temperature solution for your lab!

Visual Guide

References

- Tribological properties of silicon carbide ceramic surfaces modified by polishing, grinding and laser radiation. DOI: 10.1007/s42452-024-06004-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a vacuum hot press machine improve material properties? Achieve Superior Strength and Purity

- What is the core function of a vacuum hot press furnace in manufacturing high-density graphite/copper composites? The Forced-Wetting Solution for Superior Composites

- What are the mold configuration requirements for sintering non-conductive powders in FAST? Expert Setup Guide

- What is hot pressing and how does it work? Achieve Superior Material Density and Strength

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Cu2Se Densification and Thermoelectric Performance

- How does vacuum hot pressing compare to vacuum brazing and sintering? Choose the Right Process for Your Materials

- What is the function of Molybdenum Disulfide (MoS2) coating on molds during vacuum hot press sintering? Protect Your Samples and Molds from Damage