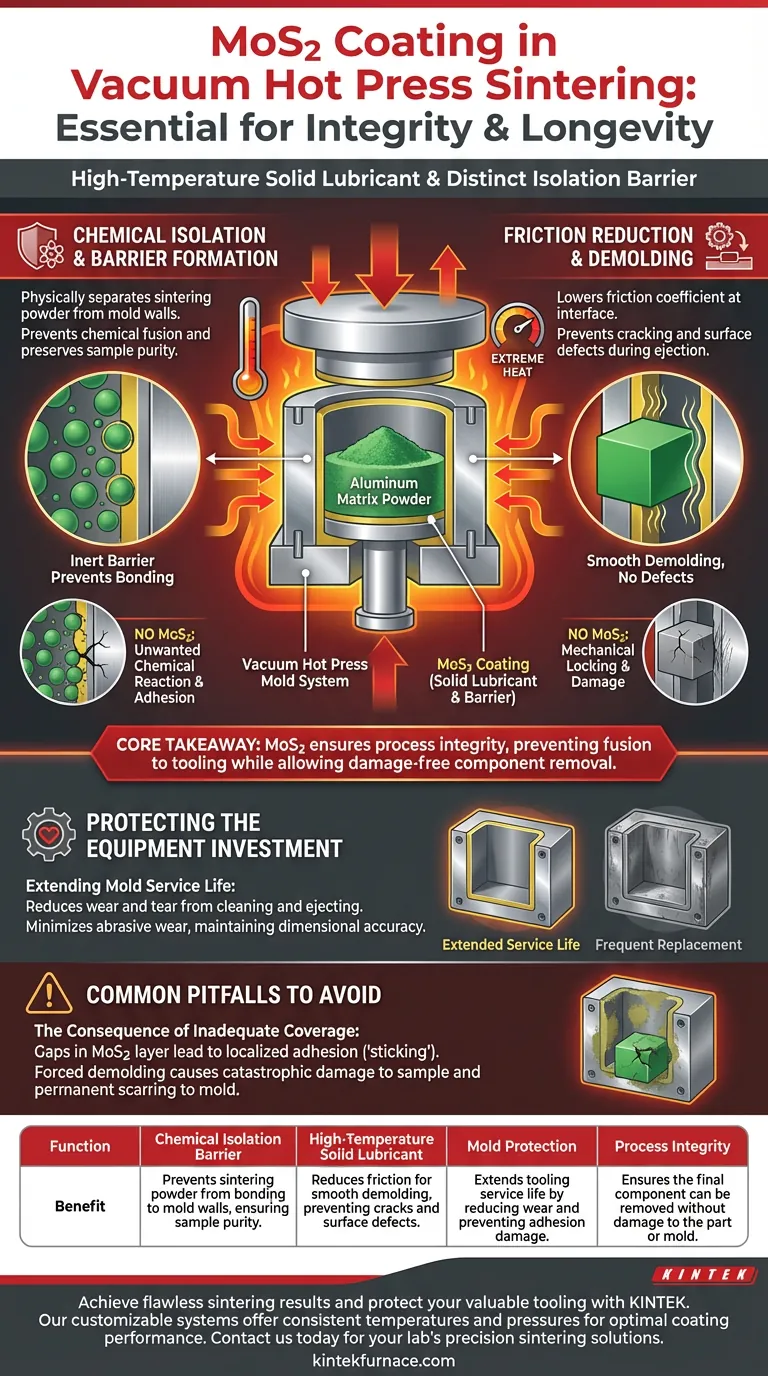

Molybdenum Disulfide (MoS2) functions primarily as a high-temperature solid lubricant and distinct isolation barrier within the sintering environment. Applied to the inner walls of molds and press heads, it creates a physical shield that prevents the sintering powder from bonding chemically or physically to the mold under extreme heat and pressure.

Core Takeaway: MoS2 is essential for process integrity; it prevents the chemical fusion of the workpiece to the tooling while simultaneously lowering friction to ensure the final component can be removed without damage.

The Mechanisms of Protection

Chemical Isolation and Barrier Formation

In vacuum hot press sintering, high temperatures and pressures create an environment ripe for unwanted chemical reactions.

MoS2 acts as an inert barrier. It physically separates the sintering powder—specifically materials like aluminum matrix powders—from the mold walls.

Without this isolation, the matrix powder would likely react with or adhere to the mold material, compromising both the sample's purity and the mold's surface.

Friction Reduction and Demolding

Beyond chemical isolation, MoS2 serves a critical mechanical function as a solid lubricant.

During the sintering process, materials densify and can become mechanically locked against the tooling.

The coating lowers the coefficient of friction at the interface, ensuring smooth demolding. This allows the sintered sample to be ejected cleanly, preventing cracking or surface defects on the finished part.

Protecting the Equipment Investment

Extending Mold Service Life

Molds used in hot pressing are often precision-machined and expensive components.

By preventing the adhesion of metal powders, MoS2 reduces the wear and tear associated with cleaning and ejecting stuck parts.

This protective layer effectively extends the service life of the mold, reducing the frequency of tooling replacement and maintaining dimensional accuracy over time.

Common Pitfalls to Avoid

The Consequence of Inadequate Coverage

The primary risk in this process is failing to achieve a uniform coating.

If gaps exist in the MoS2 layer, the aluminum matrix powder will directly contact the mold.

This leads to localized adhesion or "sticking." Once adhesion occurs, forced demolding can cause catastrophic damage to the sample and permanent scarring to the mold surface, rendering it unusable for future precision work.

Making the Right Choice for Your Goal

To maximize the success of your sintering run, focus on what you need the coating to protect most.

- If your primary focus is Sample Integrity: Ensure thorough coverage to prevent chemical reactions between the aluminum matrix and the mold, which guarantees a pure surface finish.

- If your primary focus is Equipment Longevity: Prioritize consistent re-application of MoS2 between cycles to minimize abrasive wear and prevent powder adhesion that degrades mold tolerance.

By treating the MoS2 coating as a critical process step rather than an afterthought, you safeguard both your product and your tooling assets.

Summary Table:

| Function | Benefit |

|---|---|

| Chemical Isolation Barrier | Prevents sintering powder from bonding to mold walls, ensuring sample purity. |

| High-Temperature Solid Lubricant | Reduces friction for smooth demolding, preventing cracks and surface defects. |

| Mold Protection | Extends tooling service life by reducing wear and preventing adhesion damage. |

| Process Integrity | Ensures the final component can be removed without damage to the part or mold. |

Achieve flawless sintering results and protect your valuable tooling. The right furnace system is crucial for applying consistent temperatures and pressures where coatings like MoS2 perform optimally. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for unique needs. Contact us today (#ContactForm) to find the perfect high-temperature furnace solution for your lab's precision sintering applications.

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the core advantages of high-vacuum hot press sintering for Al2O3/TiC ceramics? Achieve Near-Theoretical Density

- Why is precise temperature control critical in AlMgTi composite preparation? Mastering the 437°C Eutectic Barrier

- What is the basic principle of how a vacuum press works? Harness Atmospheric Pressure for Uniform Clamping

- What medical applications benefit from Vacuum Hot Press technology? Enhance Biocompatible Implants and Tools

- Why is precise temperature control in vacuum hot press equipment critical for regulating the mechanical properties of Fe-based amorphous alloy composites? Master the Metallurgical Balance for Superior Materials

- What are the common applications of hot press furnaces? Unlock High-Density Material Solutions

- What are the benefits of the vacuum environment system in a vacuum hot press furnace? Unlock High-Density Sintering

- What Role Does a Graphite Mold Play in Vacuum Hot Pressing? Enhancing Composite Sintering Efficiency