At its core, a vacuum press does not suck materials together. Instead, it uses a pump to remove air from a sealed bag or chamber. This creates a low-pressure environment inside, allowing the immense weight of the outside atmosphere to press down on the object, applying perfectly uniform pressure across its entire surface.

A vacuum press operates on a simple principle of pressure differential. By evacuating the air within a sealed container, it lets the constant, heavy pressure of the external atmosphere become a powerful and perfectly even clamping force.

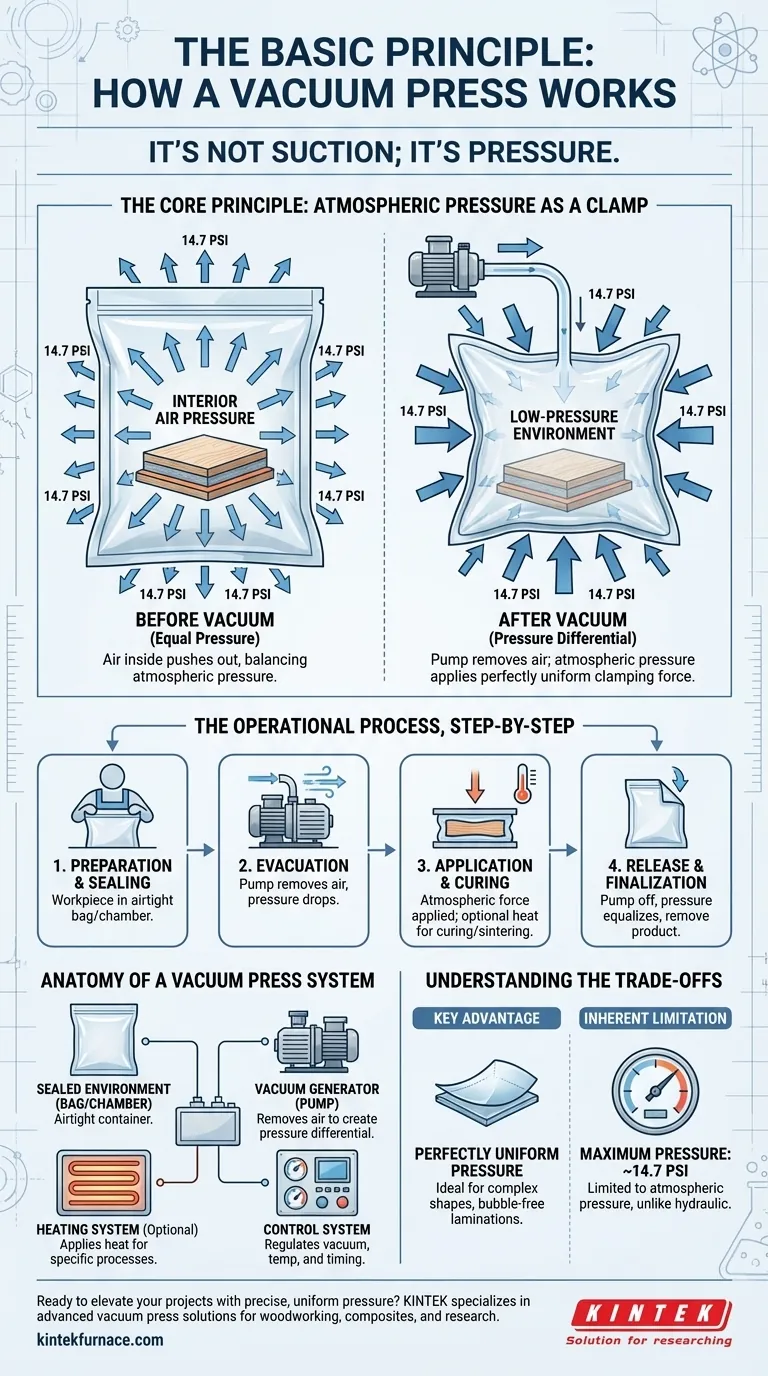

The Core Principle: Atmospheric Pressure as a Clamp

The key to understanding a vacuum press is to reframe your thinking from "suction" to "pressure." The vacuum itself does nothing but get the air out of the way.

It's Not Suction; It's Pressure

A vacuum is not a force; it is the absence of air pressure. The real work is done by the atmospheric pressure that constantly surrounds us.

At sea level, the atmosphere exerts approximately 14.7 pounds per square inch (PSI) of pressure in all directions. A vacuum press harnesses this free and powerful force.

How It Creates Force

When you place an object in a vacuum bag and remove the air, you remove the interior air that was pushing out on the bag.

With nothing pushing out from the inside, the full 14.7 PSI of the atmosphere pushes in from the outside, compressing whatever is in the bag with tremendous, even force. On a surface of just one square foot, that equates to over 2,100 pounds of clamping pressure.

Anatomy of a Vacuum Press System

A vacuum press is a system of several key components working together to control this atmospheric force.

The Sealed Environment (Bag or Chamber)

This is the airtight container, typically a flexible vinyl or polyurethane bag for applications like woodworking, or a rigid chamber for industrial processes. Its only job is to prevent outside air from getting back in.

The Vacuum Generator (The Pump)

This is the heart of the system. The pump's function is to remove air and other gases from the sealed environment, creating the pressure differential that allows the atmosphere to do its work.

The Heating System (Optional)

Many industrial and research presses are vacuum hot presses. These add a heating element to apply high temperatures simultaneously with pressure. This is critical for processes like sintering ceramics or curing advanced composite materials.

The Control System

For precision work, control systems are used to regulate vacuum levels, manage temperature, and time the process. This ensures consistent and repeatable results.

The Operational Process, Step-by-Step

Using a vacuum press follows a clear and logical sequence.

1. Preparation and Sealing

The workpiece, often along with adhesives or resins, is placed inside the bag or chamber. The container is then sealed to be completely airtight.

2. Evacuation

The vacuum pump is turned on. It draws the air out of the sealed environment, and you can see the bag collapse tightly around the workpiece as atmospheric pressure takes over.

3. Application and Curing

With the vacuum established, the atmospheric pressure is now fully applied. This is the "clamping" stage, where glues dry, laminates are pressed, or materials are densified. If it is a hot press, heat is applied during this stage.

4. Release and Finalization

Once the process is complete, the vacuum pump is turned off and air is allowed back into the bag. This equalizes the pressure and releases the clamping force, allowing the finished product to be removed.

Understanding the Trade-offs and Common Pitfalls

While powerful, the technology has inherent characteristics you must understand to use it effectively.

Key Advantage: Perfectly Uniform Pressure

This is the primary reason to use a vacuum press. Unlike mechanical clamps that concentrate force at specific points, a vacuum applies pressure evenly across every square inch of a surface, including complex curves and irregular shapes.

Inherent Limitation: Maximum Pressure

The maximum achievable pressure is limited to the local atmospheric pressure—around 14.7 PSI at sea level. For applications like woodworking and most composites, this is more than sufficient. However, it cannot compete with hydraulic presses that generate thousands of PSI for forging metal.

Common Pitfall: Leaks

The entire system's integrity depends on a perfect seal. Even a pinhole leak in the bag or a faulty seal will allow air to seep back in, causing the vacuum to degrade and the clamping pressure to fail.

How to Apply This to Your Project

Your application will determine which aspects of the technology are most important.

- If your primary focus is woodworking or veneering: The uniform pressure is your greatest asset for achieving flawless, bubble-free laminations on flat and curved panels.

- If your primary focus is creating advanced composites: You need a system that combines vacuum for densification and removing volatiles with a heating system to properly cure the resins.

- If your primary focus is materials research or sintering: You need a vacuum hot press for its ability to create an oxygen-free, high-temperature, and high-pressure environment to form new materials.

By understanding that you are simply harnessing the weight of the atmosphere, you can effectively apply this technology to achieve superior results in your work.

Summary Table:

| Component | Function |

|---|---|

| Sealed Environment (Bag/Chamber) | Creates an airtight space to maintain vacuum |

| Vacuum Generator (Pump) | Removes air to create pressure differential |

| Heating System (Optional) | Applies heat for processes like curing or sintering |

| Control System | Regulates vacuum, temperature, and timing for precision |

Ready to elevate your projects with precise, uniform pressure? KINTEK specializes in advanced vacuum press solutions tailored for woodworking, composites, and materials research. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs—from standard setups to high-temperature vacuum hot presses. Contact us today to discuss how our expertise can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals