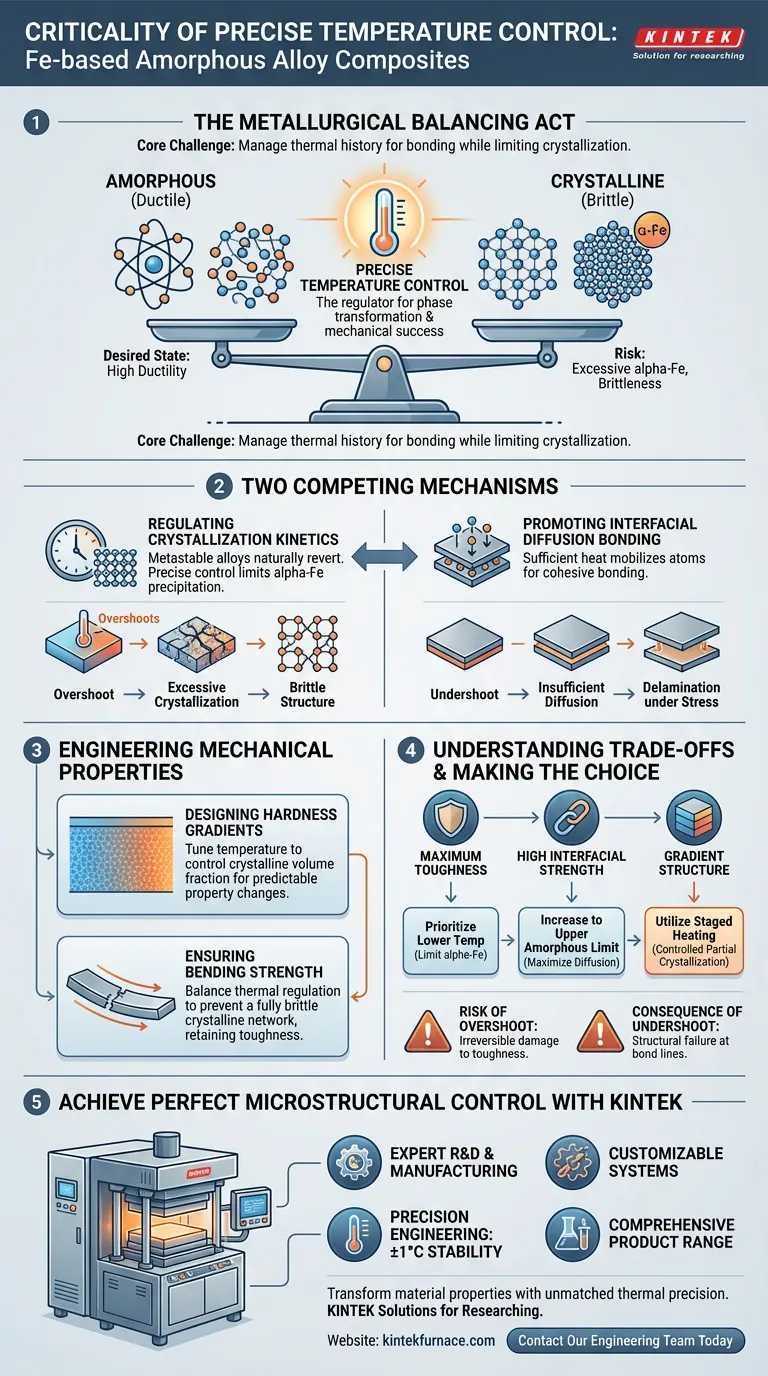

Precise temperature control in vacuum hot press equipment is the single most critical variable for determining the mechanical success of Fe-based amorphous alloy composites. It acts as the regulator for the material’s phase transformation, directly dictating whether the alloy retains its desirable amorphous properties or degrades into a brittle structure due to excessive crystallization.

The core challenge lies in managing the thermal history to permit sufficient interfacial diffusion for bonding while strictly limiting the precipitation of the alpha-Fe phase, ensuring the composite achieves a wide hardness gradient without sacrificing bending strength.

The Metallurgical Balancing Act

In the processing of Fe-based amorphous alloys, temperature is not just a catalyst for consolidation; it is a switch that controls the material's fundamental state. The equipment must navigate a narrow processing window to achieve two competing objectives.

Regulating Crystallization Kinetics

Fe-based amorphous alloys are metastable. When exposed to heat, they naturally want to revert to a crystalline state.

Precise control determines the extent of this transformation, specifically the precipitation of the alpha-Fe phase.

If the temperature overshoots, the material undergoes excessive crystallization, causing the amorphous layer to lose its unique ductility and become inherently brittle.

Promoting Interfacial Diffusion Bonding

While minimizing crystallization is crucial, sufficient heat is still required to consolidate the composite.

The temperature must be high enough to mobilize atoms at the interface between layers.

This diffusion bonding is essential for creating a cohesive composite; without it, the layers will simply delaminate under stress.

Engineering Mechanical Properties via Thermal Control

The ultimate goal of using vacuum hot press equipment is to design specific mechanical traits into the final product. Temperature precision is the tool used to "program" these traits.

Designing Hardness Gradients

By finely tuning the temperature, operators can control the volume fraction of the crystalline phase.

This capability enables the design of composites with wide hardness gradients, where properties change predictably across the material's cross-section.

Ensuring Bending Strength

A fully amorphous material may be strong but lacks certain structural benefits, while a fully crystalline one is often too brittle.

Correct thermal regulation ensures the material retains excellent bending strength by preventing the formation of a fully brittle crystalline network.

Understanding the Trade-offs

Achieving the perfect composite requires accepting and managing specific trade-offs inherent to the vacuum hot press process.

The Risk of Thermal Overshoot

Even a slight deviation above the target temperature can trigger a "runaway" crystallization event.

Once the alpha-Fe phase precipitates beyond a certain threshold, the damage to the material's toughness is irreversible.

The Consequence of Undershooting

Conversely, operating too conservatively with temperature to protect the amorphous state often leads to structural failure.

If the heat is insufficient to drive diffusion, the resulting composite will lack structural integrity and fail at the bond lines rather than within the material itself.

Making the Right Choice for Your Goal

To leverage precise temperature control effectively, you must align your thermal parameters with your specific performance objectives.

- If your primary focus is Maximum Toughness: Prioritize lower temperature ranges that strictly limit alpha-Fe precipitation to preserve the amorphous nature of the alloy.

- If your primary focus is High Interfacial Strength: Increase the temperature to the upper limit of the amorphous stability window to maximize diffusion bonding without fully crystallizing the matrix.

- If your primary focus is a Gradient Structure: Utilize a staged heating approach to induce controlled, partial crystallization in specific regions while leaving others amorphous.

Mastering temperature control turns the vacuum hot press from a simple heating tool into an instrument for microstructural design.

Summary Table:

| Temperature Control Objective | Desired Outcome | Risk of Deviation |

|---|---|---|

| Regulate Crystallization Kinetics | Preserve amorphous ductility | Excessive alpha-Fe precipitation, brittleness |

| Promote Interfacial Diffusion Bonding | Strong, cohesive composite layers | Delamination under stress |

| Design Hardness Gradients | Controlled property variation across material | Unpredictable mechanical performance |

| Ensure Bending Strength | Optimal balance of strength and toughness | Fully brittle crystalline network |

Achieve Perfect Microstructural Control with KINTEK's Advanced Vacuum Hot Press Solutions

Struggling to maintain the delicate thermal balance required for high-performance Fe-based amorphous alloy composites? Our precision vacuum hot press equipment delivers the exact temperature control you need to prevent crystallization while ensuring strong interfacial bonding.

Why Choose KINTEK?

- Expert R&D and Manufacturing: Backed by decades of experience in high-temperature processing equipment

- Customizable Systems: Tailored vacuum hot press solutions designed for your specific material requirements

- Precision Engineering: Achieve ±1°C temperature stability for reproducible results

- Comprehensive Product Range: From lab-scale research units to industrial production systems

Perfect for: Materials scientists, R&D labs, and manufacturing engineers working with amorphous alloys, composites, and advanced materials requiring precise thermal management.

Ready to transform your material properties with unmatched temperature precision? Contact our engineering team today for a customized solution that meets your exact research or production needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a vacuum hot press work? Unlock Superior Material Density and Purity

- How to maintain a vacuum machine? Ensure long-term reliability and peak performance

- What are the technical advantages of a Spark Plasma Sintering (SPS) system? Achieve Superior TiB2 Ceramic Performance

- How does a vacuum hot pressing furnace contribute to high-hardness composites? Achieve Near-Theoretical Density

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication

- How does a Vacuum Hot-Pressing Furnace facilitate the densification of CaF2? Achieve High Optical Transparency

- What role does a vacuum hot press furnace play in the densification of nanocomposites? Achieve Near-Theoretical Density

- What are the unique advantages of Spark Plasma Sintering (SPS)? Unlock Ultrafine Carbide Strength