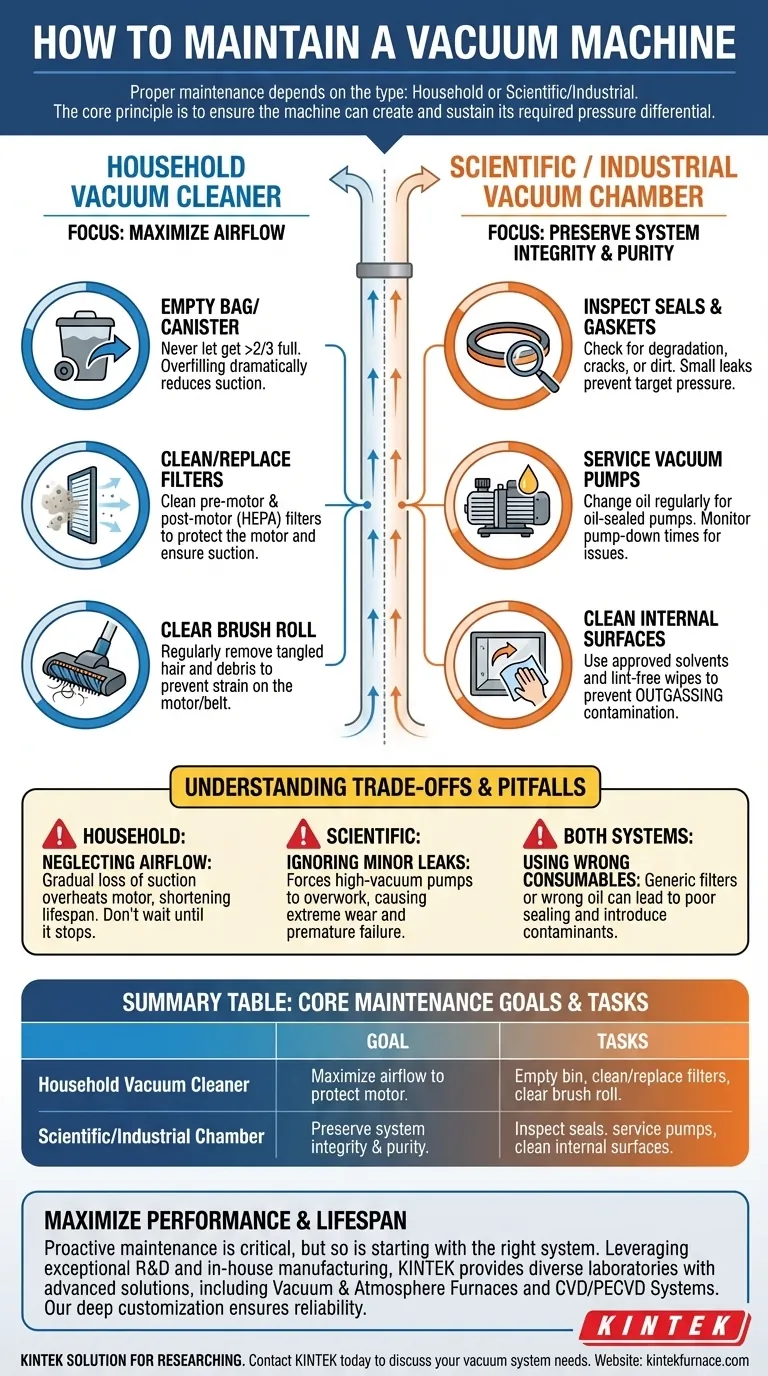

To properly maintain a vacuum machine, you must first identify its type, as the procedures are entirely different. For a household vacuum cleaner, the most critical tasks are regularly emptying the dirt canister and cleaning the filters to ensure proper airflow. For a scientific or industrial vacuum chamber, maintenance focuses on preserving system integrity by inspecting seals for leaks and servicing the pumps that create the low-pressure environment.

The core principle of all vacuum system maintenance is the same: ensure the machine can create and sustain its required pressure differential. Whether this means preventing clogs in a cleaner or sealing leaks in a chamber, the goal is to reduce strain and guarantee performance.

Understanding Vacuum Cleaner Maintenance

A vacuum cleaner’s performance is entirely dependent on the volume of air it can move. Every maintenance task is designed to maximize this airflow, which protects the motor and ensures strong suction.

The Core Principle: Unobstructed Airflow

Your vacuum's motor creates suction by pulling air through the machine. Any clog, blockage, or dirty filter forces the motor to work harder, generating excess heat and leading to premature failure.

Emptying the Bag or Canister

Never let the bag or canister get more than two-thirds full. An overfilled container dramatically reduces suction power long before it appears "full" and can cause fine dust to be forced into the motor compartment.

Cleaning and Replacing Filters

Vacuums have multiple filters, typically a pre-motor filter to protect the engine from dust and a post-motor (often HEPA) filter to clean the exhaust air. Clogged filters starve the motor of air, so they should be cleaned or replaced according to the manufacturer's schedule—or more often in dusty environments.

Clearing the Brush Roll

The spinning brush roll (or beater bar) is essential for agitating carpet fibers. Regularly cut away tangled hair, string, and debris. A tangled brush roll cannot spin effectively and can strain or burn out its dedicated motor or drive belt.

Maintaining a Scientific or Industrial Vacuum Chamber

For a high-vacuum chamber, maintenance shifts from airflow to system purity and integrity. The goal is to remove molecules from a sealed environment, so preventing them from entering (leaks) or being introduced (outgassing) is paramount.

The Core Principle: System Integrity

A vacuum chamber's performance is measured by the low pressure (or "high vacuum") it can achieve and hold. This requires a perfectly sealed system and clean internal surfaces.

Seal and Gasket Inspection

The most common point of failure is a leak at a seal, flange, or viewport. O-rings and gaskets made of elastomers can degrade, crack, or become dirty over time. A small, invisible leak can prevent the system from reaching its target pressure.

Vacuum Pump Maintenance

The pumps are the heart of the system. For oil-sealed rotary vane pumps (a common type of roughing pump), changing the oil is critical. Contaminated oil has a higher vapor pressure, limiting the vacuum level the pump can achieve. Monitor pump-down times; a sudden increase can indicate a leak or a pump issue.

Chamber Cleanliness and Outgassing

Any material, including fingerprints or cleaning residue, on the chamber's internal surfaces can release molecules under vacuum. This phenomenon, called outgassing, raises the chamber pressure and can contaminate your experiment or process. Always use approved, low-vapor-pressure solvents (like isopropyl alcohol) and lint-free wipes for cleaning.

Understanding the Trade-offs and Pitfalls

Neglecting maintenance has direct consequences, but they manifest differently in each system. Understanding these specific risks helps prioritize your efforts.

For Vacuum Cleaners: "If It's Sucking, It's Working"

This is a dangerous misconception. A gradual loss of suction is the first sign of a clogged filter or a developing blockage. Ignoring it forces the motor to overheat, significantly shortening the lifespan of the appliance.

For Vacuum Chambers: Neglecting Minor Leaks

A "small" leak may seem insignificant if the pumps can overcome it, but this is deceptive. It forces the high-vacuum pumps (like turbomolecular or diffusion pumps) to work constantly against a gas load they aren't designed for, causing extreme wear and premature failure.

For Both Systems: Using the Wrong Consumables

Using a generic filter in a vacuum cleaner can lead to poor sealing and allow dust into the motor. Using the wrong oil in a vacuum pump or an unapproved cleaning agent in a chamber can introduce contaminants that are nearly impossible to remove, ruining the system's performance.

A Maintenance Checklist for Your Goal

Your maintenance strategy should be guided by the primary function of your equipment.

- If your primary focus is a household vacuum cleaner: Prioritize consistent airflow. Regularly empty the bin, wash or replace the filters, and keep the brush roll free of debris.

- If your primary focus is a scientific vacuum chamber: Prioritize system integrity. Routinely inspect all seals for leaks, follow the maintenance schedule for your specific pumps, and maintain rigorous internal cleanliness to prevent outgassing.

Proactive and correct maintenance is the definitive factor in ensuring the long-term reliability and performance of any vacuum system.

Summary Table:

| Vacuum System Type | Core Maintenance Goal | Key Maintenance Tasks |

|---|---|---|

| Household Vacuum Cleaner | Maximize airflow to protect motor and suction | - Empty bag/canister regularly - Clean/replace filters - Clear brush roll of debris |

| Scientific/Industrial Chamber | Preserve system integrity and purity | - Inspect seals and gaskets for leaks - Service vacuum pumps (e.g., change oil) - Clean internal surfaces to prevent outgassing |

Maximize the performance and lifespan of your laboratory equipment. Proper maintenance is critical, but so is starting with the right, high-integrity vacuum system for your specific application. Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet unique experimental requirements, ensuring your system is built for reliability from the start.

Contact KINTEK today to discuss your vacuum system needs and discover how our tailored solutions can enhance your research and development.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- What are the key applications of vacuum pressing in composite material processing? Enhance Material Quality and Shape Complexity