At its core, a vacuum hot press is an advanced manufacturing tool that simultaneously applies high temperature and immense mechanical pressure to a material inside a vacuum-sealed chamber. This sophisticated process is designed to consolidate powders, densify pre-formed parts, or bond dissimilar materials together into a single, solid piece with superior structural integrity. It fundamentally transforms materials by eliminating internal voids and preventing chemical contamination.

The true value of a vacuum hot press isn't just the application of heat and pressure; it's the use of a vacuum. By removing air and other reactive gases, the process prevents oxidation and contamination, enabling the creation of exceptionally pure, dense, and high-performance materials that would be impossible to produce in a standard atmosphere.

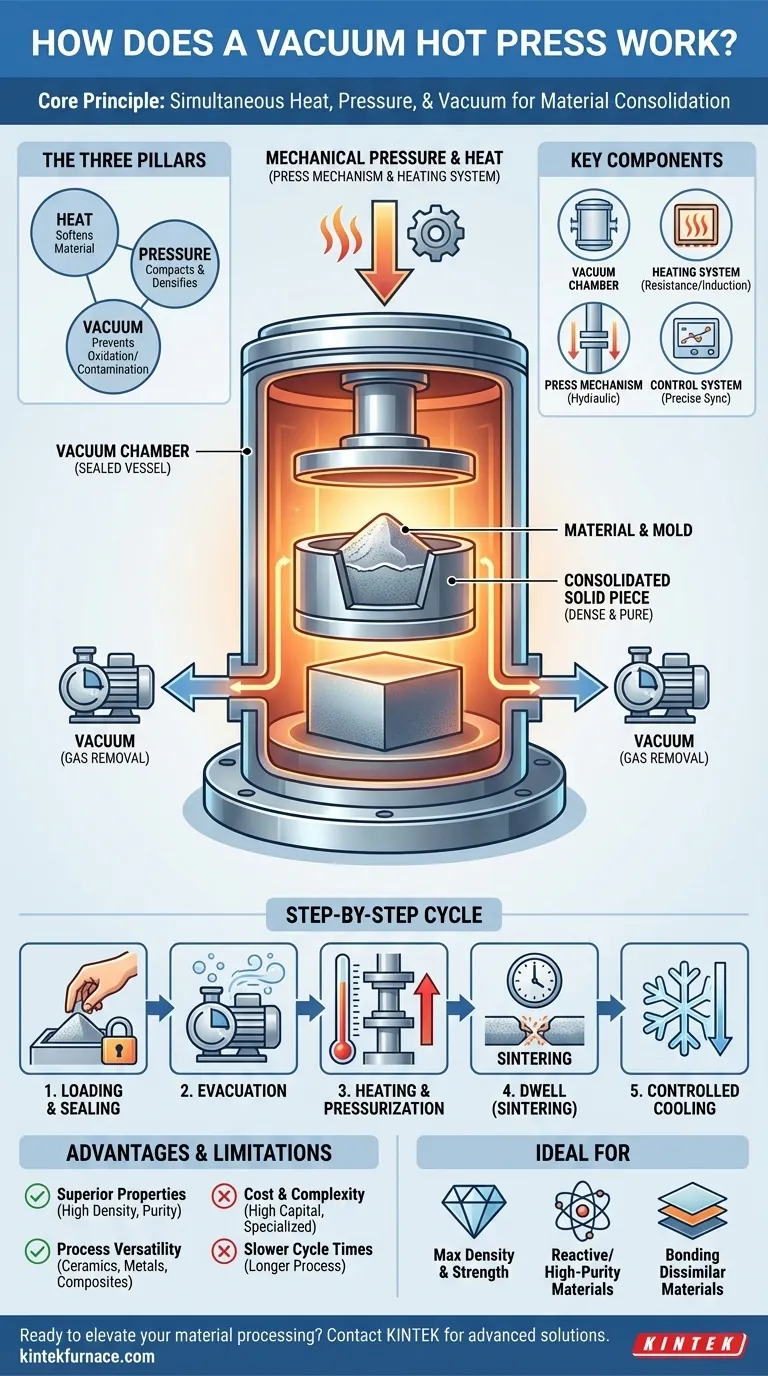

The Three Pillars of the Process

A vacuum hot press operates on the precise synchronization of three environmental factors: heat, pressure, and vacuum. Understanding the role of each is key to understanding the technology.

The Role of High Temperature

Heat provides the thermal energy required to soften the material on a microscopic level. This increased atomic mobility allows particles to diffuse and bond with one another, a process essential for fusing powders into a solid mass.

The Function of Mechanical Pressure

While heat enables bonding, mechanical pressure is the driving force that physically compacts the material. The press mechanism applies a uniform force, collapsing pores and voids to dramatically increase the final component's density and mechanical strength.

The Critical Importance of the Vacuum

The vacuum is the defining feature. By evacuating the chamber, reactive gases like oxygen and nitrogen are removed. This prevents the formation of undesirable oxides and nitrides, especially when working with reactive materials like titanium, advanced ceramics, or refractory metals.

A Look Inside the Machine: Key Components

The synergy of heat, pressure, and vacuum is managed by four critical systems working in concert.

The Vacuum Chamber

This is the heavy-duty, sealed vessel that contains the entire process. It is designed to withstand both extreme internal temperatures and external atmospheric pressure when a vacuum is drawn.

The Heating System

Precise temperature control is paramount. This is typically achieved through resistance heating elements surrounding the workpiece or through induction heating, which uses electromagnetic fields to generate heat directly within the material or its mold.

The Press Mechanism

This system, often powered by hydraulics, applies the compressive force. It is engineered to exert consistent and uniform pressure across the material's surface to ensure even densification and prevent structural flaws.

The Control System

This is the brain of the operation. A sophisticated control system monitors and synchronizes the vacuum level, temperature ramp-up rate, pressure application, and cooling cycle, executing a precise recipe for a given material.

The Step-by-Step Operational Cycle

A typical production cycle follows a clear, sequential path to ensure quality and repeatability.

Step 1: Loading and Sealing

The raw material, often in powder form or as a pre-shaped "preform," is placed into a high-strength mold (typically graphite). The mold assembly is then loaded into the press, and the vacuum chamber is sealed shut.

Step 2: Evacuation

High-performance pumps activate to remove the air from the chamber, creating the low-pressure vacuum environment required for the process.

Step 3: Heating and Pressurization

The heating system begins to raise the temperature according to a pre-programmed profile. Simultaneously, or at a specific temperature, the press mechanism applies force.

Step 4: Dwell (Sintering)

The material is held at peak temperature and pressure for a specified duration. During this "dwell" or sintering phase, the material fully consolidates, particles bond, and density approaches its theoretical maximum.

Step 5: Controlled Cooling

Once the dwell time is complete, the system begins a controlled cooling sequence. This is often done slowly and under vacuum to prevent thermal shock, which could crack or damage the newly formed component.

Understanding the Advantages and Limitations

While powerful, a vacuum hot press is a specialized tool with clear trade-offs.

Advantage: Superior Material Properties

The process creates parts with near-100% density, minimal porosity, and exceptional purity. This translates directly to superior mechanical strength, hardness, and performance.

Advantage: Process Versatility

This technology is effective for a vast range of materials, including advanced ceramics, metals, alloys, and composite materials, making it a cornerstone of advanced materials research and production.

Limitation: Cost and Complexity

Vacuum hot presses are significant capital investments. They are complex machines that require specialized knowledge for operation and maintenance, leading to higher operational costs compared to simpler furnace technologies.

Limitation: Slower Cycle Times

The need to pump down a vacuum, heat up, dwell, and cool down in a controlled manner results in much longer cycle times per part compared to high-volume manufacturing methods like metal injection molding or conventional pressing.

Making the Right Choice for Your Goal

Selecting this process depends entirely on the required outcome for your material.

- If your primary focus is achieving maximum density and mechanical strength: A vacuum hot press is the premier choice for creating fully dense, non-porous components with exceptional physical properties.

- If your primary focus is processing reactive or high-purity materials: The vacuum environment is non-negotiable for preventing oxidation and contamination in materials like titanium, refractory metals, and certain technical ceramics.

- If your primary focus is bonding dissimilar materials: This process excels at creating strong, clean diffusion bonds between different layers of material that are otherwise difficult to join.

- If your primary focus is cost-effective, high-volume production: You should evaluate alternative methods like powder metallurgy or sintering in a standard atmosphere, as the cost and cycle time may be prohibitive.

By understanding this interplay of heat, pressure, and vacuum, you are equipped to decide when this powerful process is the right tool to achieve uncompromising material quality.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Simultaneous application of high temperature and mechanical pressure in a vacuum-sealed chamber |

| Key Components | Vacuum chamber, heating system (resistance/induction), press mechanism (hydraulic), control system |

| Steps | 1. Loading and sealing 2. Evacuation 3. Heating and pressurization 4. Dwell (sintering) 5. Controlled cooling |

| Advantages | Superior material properties (high density, purity), versatility for ceramics, metals, composites |

| Limitations | High cost, complexity, slower cycle times compared to other methods |

| Ideal For | Achieving maximum density, processing reactive materials, bonding dissimilar materials |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're working with advanced ceramics, metals, or composites, our vacuum hot press technologies can help you achieve superior density and contamination-free results. Contact us today to discuss how we can support your goals and deliver reliable, high-performance solutions!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision