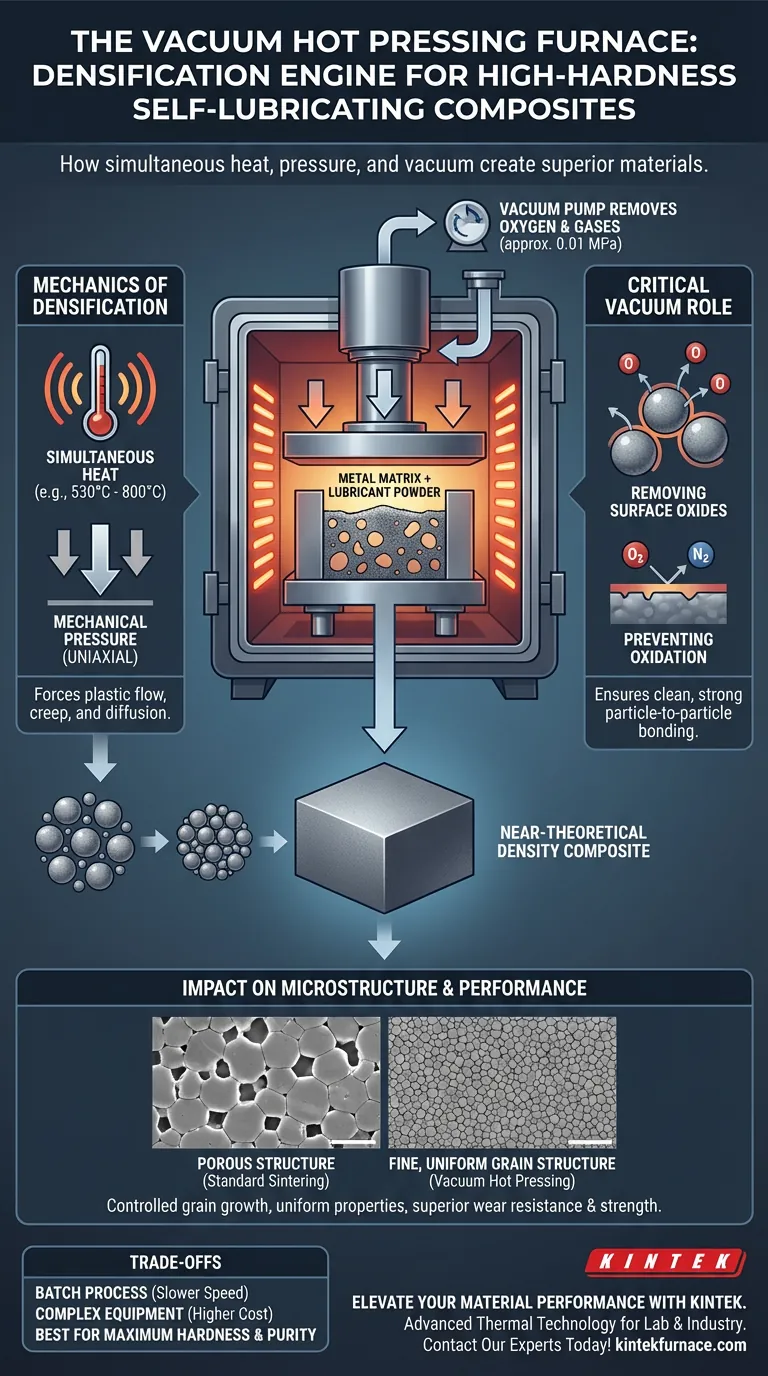

A vacuum hot pressing furnace acts as the critical densification engine for high-performance composites. It works by applying substantial mechanical pressure simultaneously with high thermal energy within an oxygen-free environment. This unique combination forces powder particles to bond tightly, eliminating voids that would otherwise weaken the final material.

Core Takeaway The vacuum hot pressing furnace is essential for producing high-hardness materials because it achieves near-theoretical density through the simultaneous application of heat and uniaxial pressure. By removing oxide films and preventing oxidation, it ensures a clean, strong bond between the metal matrix and lubricating particles, directly resulting in superior wear resistance and mechanical strength.

The Mechanics of Densification

Simultaneous Heat and Pressure

The defining feature of this furnace is the application of mechanical pressure (e.g., uniaxial pressure) at the same time as high-temperature heating (often between 530°C and 800°C).

While heat promotes the diffusion between powder particles, the mechanical pressure actively forces the material together.

Eliminating Porosity

In standard sintering, pores may remain between particles. In vacuum hot pressing, the applied pressure drives plastic flow and creep mechanisms.

This physically forces the material to fill voids, significantly reducing porosity and achieving densities that approach the theoretical limit of the material.

The Critical Role of the Vacuum Environment

Removing Surface Oxides

The primary reference highlights that the vacuum environment is not just passive; it actively removes oxide films from the surface of the powder particles.

Oxide films act as barriers to bonding. By stripping them away, the furnace enables direct particle-to-particle contact, which is essential for high hardness.

Preventing Oxidative Degradation

High temperatures usually accelerate oxidation, which degrades metal matrices. The vacuum (often around 0.01 MPa) removes harmful gases like oxygen, nitrogen, and water vapor.

This prevents the oxidation and carburization of the metal matrix, ensuring the composite maintains its intended chemical purity and strength.

Ensuring Clean Interface Bonding

For self-lubricating composites, which often mix metals with ceramics or lubricants, the interface between these distinct materials is a potential weak point.

The vacuum promotes degassing and impurity removal, creating a clean, microscopic interface bond. This strong bond prevents the material from crumbling under stress or friction.

Impact on Microstructure and Performance

Controlling Grain Growth

High-hardness materials rely on fine grain structures. Because the furnace applies high pressure, it can often achieve densification at relatively lower temperatures compared to pressureless sintering.

This helps suppress grain growth during the process. Smaller grains typically result in harder, tougher materials.

Uniformity and Stability

Advanced vacuum furnaces utilize high-precision control systems to regulate temperature, pressure, and suppression rates.

This precision results in a uniform material structure across the entire sample, ensuring that the hardness and self-lubricating properties are consistent and reliable in every part of the component.

Understanding the Trade-offs

Process Speed and Volume

Vacuum hot pressing is typically a batch process, unlike continuous sintering methods.

It requires time to pump down the vacuum, heat the chamber, apply pressure, and cool down under controlled conditions. This generally makes it slower and less suitable for massive, high-speed production runs compared to conventional conveyor sintering.

Equipment Complexity

The requirement for maintaining a high vacuum while applying tons of mechanical force adds complexity.

These furnaces require robust insulation, sophisticated seals, and advanced control systems to manage the energy and forces involved. This contributes to higher capital and operational costs compared to atmospheric furnaces.

Making the Right Choice for Your Goal

When deciding if vacuum hot pressing is the right manufacturing route for your composite material, consider your specific performance requirements.

- If your primary focus is Maximum Hardness and Density: Choose vacuum hot pressing. The combination of pressure and vacuum is the only reliable way to achieve near-theoretical density and pore-free structures.

- If your primary focus is Material Purity: Choose this method to ensure the complete removal of oxide films and the prevention of high-temperature oxidation, which is critical for high-quality bonding.

- If your primary focus is High-Volume, Low-Cost Production: Evaluate if pressureless sintering can meet your minimum specs, as hot pressing is a more resource-intensive batch process.

Ultimately, for high-hardness self-lubricating composites, the vacuum hot pressing furnace is not just an option—it is a prerequisite for achieving the structural integrity required for demanding industrial applications.

Summary Table:

| Feature | Vacuum Hot Pressing Impact | Benefit for Composites |

|---|---|---|

| Pressure Application | Uniaxial pressure during heating | Eliminates voids & achieves near-theoretical density |

| Vacuum Environment | Removes oxide films & harmful gases | Prevents oxidation and ensures pure bonding interfaces |

| Temperature Control | Precise heating (530°C - 800°C) | Suppresses grain growth for a harder, tougher structure |

| Microstructure | Plastic flow & creep mechanisms | Consistent uniformity and superior mechanical strength |

Elevate Your Material Performance with KINTEK

Unlock the full potential of your high-performance composites with KINTEK’s advanced thermal technology. Backed by expert R&D and world-class manufacturing, KINTEK offers high-precision Vacuum, Muffle, Tube, Rotary, and CVD systems tailored to your specific lab and industrial requirements. Whether you are developing high-hardness self-lubricating materials or advanced ceramics, our customizable high-temperature furnaces provide the pressure and purity your research demands.

Ready to optimize your densification process?

→ Contact Our Experts Today for a Custom Solution

Visual Guide

References

- Huifeng Ning, Litian Hu. Modeling and prediction of tribological properties of copper/aluminum-graphite self-lubricating composites using machine learning algorithms. DOI: 10.1007/s40544-023-0847-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a hot pressing furnace equipped with a vacuum system necessary for sintering high-entropy alloy coatings? Ensure Purity, Density, and Superior Performance

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How does an industrial-grade hot press sintering system benefit Al2O3/TiC/SiC(w) ceramics? Enhanced Material Density

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- How does the pressurization system in a vacuum hot press furnace overcome AMC interface issues? Achieve Peak Density

- How does the vacuum environment affect AlMgTi composite hot pressing? Unlock Superior Bonding & Density

- What safety features are incorporated in vacuum hot press furnaces? Ensure Operator and Equipment Protection

- What are the characteristics of ultrahigh pressure sintering for ceramics? Achieve Dense, Fine-Grained Ceramics