At its core, ultrahigh pressure sintering is a materials processing technique that uses extreme pressure—hundreds of thousands of atmospheres—to rapidly forge ceramic powders into a dense, solid state. This process achieves a fine-grained microstructure and can even alter the fundamental crystal structure of a material, unlocking unique properties that are impossible to obtain through conventional sintering methods.

Ultrahigh pressure sintering should not be viewed as merely an enhanced version of conventional heating. It is a specialized tool that uses immense physical force to create novel material states, enabling the development of next-generation ceramics with unprecedented performance.

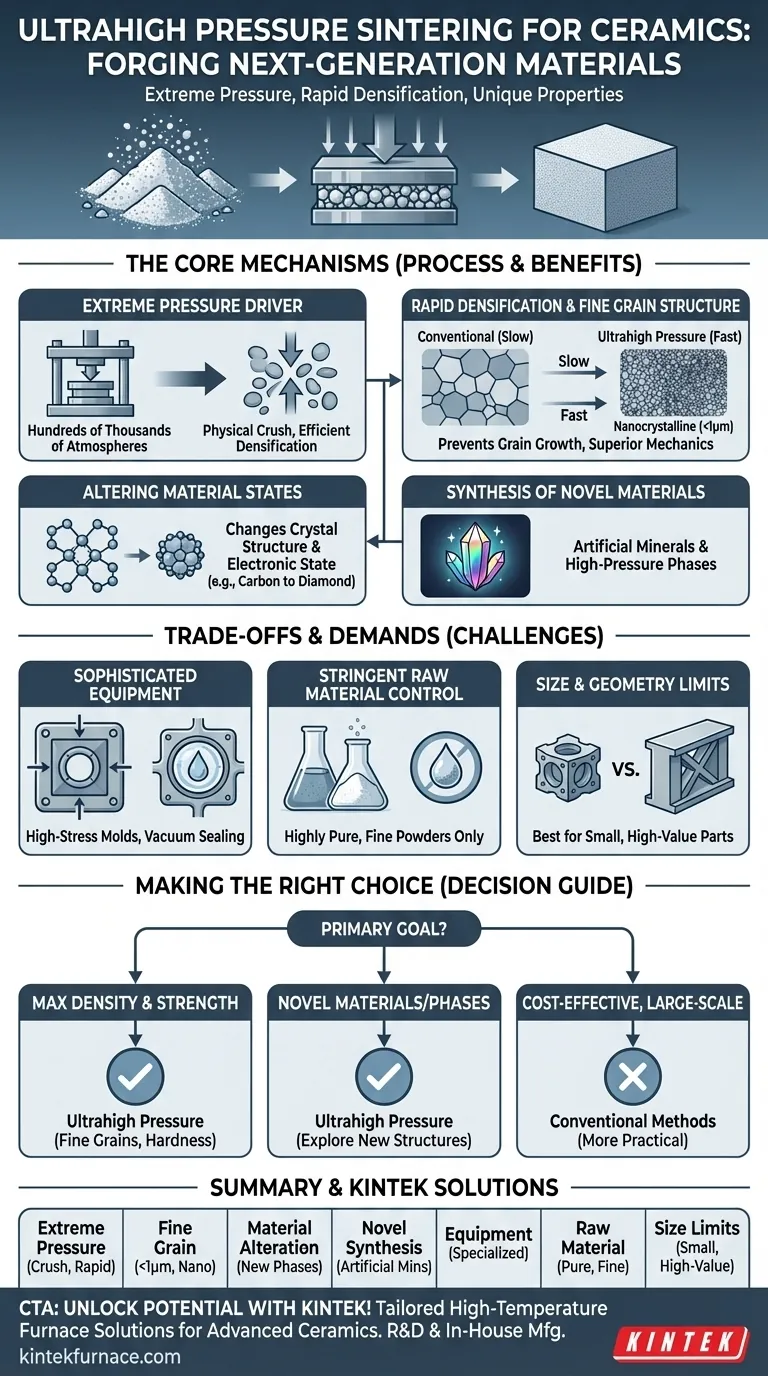

The Core Mechanisms of Ultrahigh Pressure Sintering

To understand why this method is used, we must look at how extreme pressure fundamentally changes the sintering process. It moves beyond simple diffusion and particle bonding to physically compel densification.

Extreme Pressure as the Driving Force

Sintering at "hundreds of thousands of atmospheres" means applying a pressure that is orders of magnitude greater than conventional hot pressing. This immense force physically crushes particles together, eliminating voids and pores with incredible efficiency. This mechanical pressure becomes the dominant driver of densification, far more so than thermal energy alone.

Rapid Densification and Fine Grain Structures

A key advantage of this process is its speed. Because the pressure is so effective at eliminating porosity, full density can be achieved very quickly. This rapid cycle prevents grain growth, a common issue in slower, high-temperature sintering where small grains merge into larger ones. The result is a highly desirable nanocrystalline or fine-grained microstructure (typically with grains less than 1 micrometer), which is critical for superior mechanical properties.

Altering Fundamental Material States

Perhaps the most unique characteristic of ultrahigh pressure is its ability to alter the crystal structure and electronic state of a material. Just as pressure can turn carbon into a diamond, it can force atoms in a ceramic into a more compact, and often entirely new, arrangement. This creates a new phase of the material with distinct properties.

Synthesis of Novel Materials

This ability to induce phase transitions allows for the synthesis of materials that cannot be formed at atmospheric pressure. This includes creating artificial minerals and other high-pressure phases with unique electronic, optical, or mechanical characteristics, opening doors for material discovery.

Understanding the Trade-offs and Demands

The exceptional results of ultrahigh pressure sintering come with significant technical challenges and costs. It is not a universally applicable solution.

Sophisticated Equipment Requirements

Generating and containing such extreme pressures requires highly specialized and expensive equipment. The molds must be made from advanced materials capable of withstanding immense stress without deforming or failing. Furthermore, precise vacuum sealing technology is essential to prevent gas entrapment, which would create defects in the final part.

Stringent Raw Material Control

The process is highly sensitive to the starting materials. To achieve optimal results, one must use highly pure and extremely fine raw material powders. Any impurities can create weak points, and inconsistent particle sizes can lead to incomplete densification. This adds to the overall cost and complexity of the manufacturing workflow.

Limitations on Size and Geometry

The immense pressures involved place practical limits on the size and complexity of the components that can be produced. The pressure chambers and mold assemblies are costly and difficult to scale, making this method best suited for producing smaller, high-value parts rather than large structural components.

Making the Right Choice for Your Goal

Deciding whether to use ultrahigh pressure sintering depends entirely on whether the final performance requirements justify the complexity and cost.

- If your primary focus is achieving maximum density and strength: This method is unparalleled for creating nearly defect-free ceramics with exceptionally fine grain structures, which directly translates to superior hardness and toughness.

- If your primary focus is developing novel materials or phases: Use ultrahigh pressure to explore new crystal structures and synthesize compounds that cannot be formed under conventional conditions.

- If your primary focus is cost-effective, large-scale production: Conventional sintering or hot pressing are almost always more practical choices due to the high equipment costs and scalability limitations of ultrahigh pressure systems.

By leveraging extreme pressure, this method moves beyond simple consolidation to fundamentally re-engineer materials at an atomic level for peak performance.

Summary Table:

| Characteristic | Description |

|---|---|

| Extreme Pressure | Applies hundreds of thousands of atmospheres to crush particles, driving rapid densification. |

| Fine Grain Structure | Prevents grain growth, resulting in nanocrystalline or fine-grained microstructures (<1 μm). |

| Material State Alteration | Changes crystal structure and electronic states, enabling new phases and properties. |

| Novel Material Synthesis | Creates artificial minerals and high-pressure phases with unique characteristics. |

| Equipment Requirements | Needs specialized, expensive molds and vacuum sealing for high-pressure containment. |

| Raw Material Control | Requires highly pure, fine powders to avoid defects and ensure optimal densification. |

| Size and Geometry Limits | Best for small, high-value parts due to scalability challenges and high costs. |

Unlock the potential of ultrahigh pressure sintering for your advanced ceramic applications with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're aiming for maximum density, fine grain structures, or novel material synthesis, KINTEK delivers reliable, high-performance equipment. Contact us today to discuss how our solutions can enhance your research and development!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- How does the use of vacuum in hot-pressing affect the material processing? Achieve Denser, Purer, and Stronger Materials

- How does induction heating ensure precision in manufacturing processes? Achieve Superior Thermal Control & Repeatability

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What is the process of hot pressing? A Guide to Achieving Superior Material Density