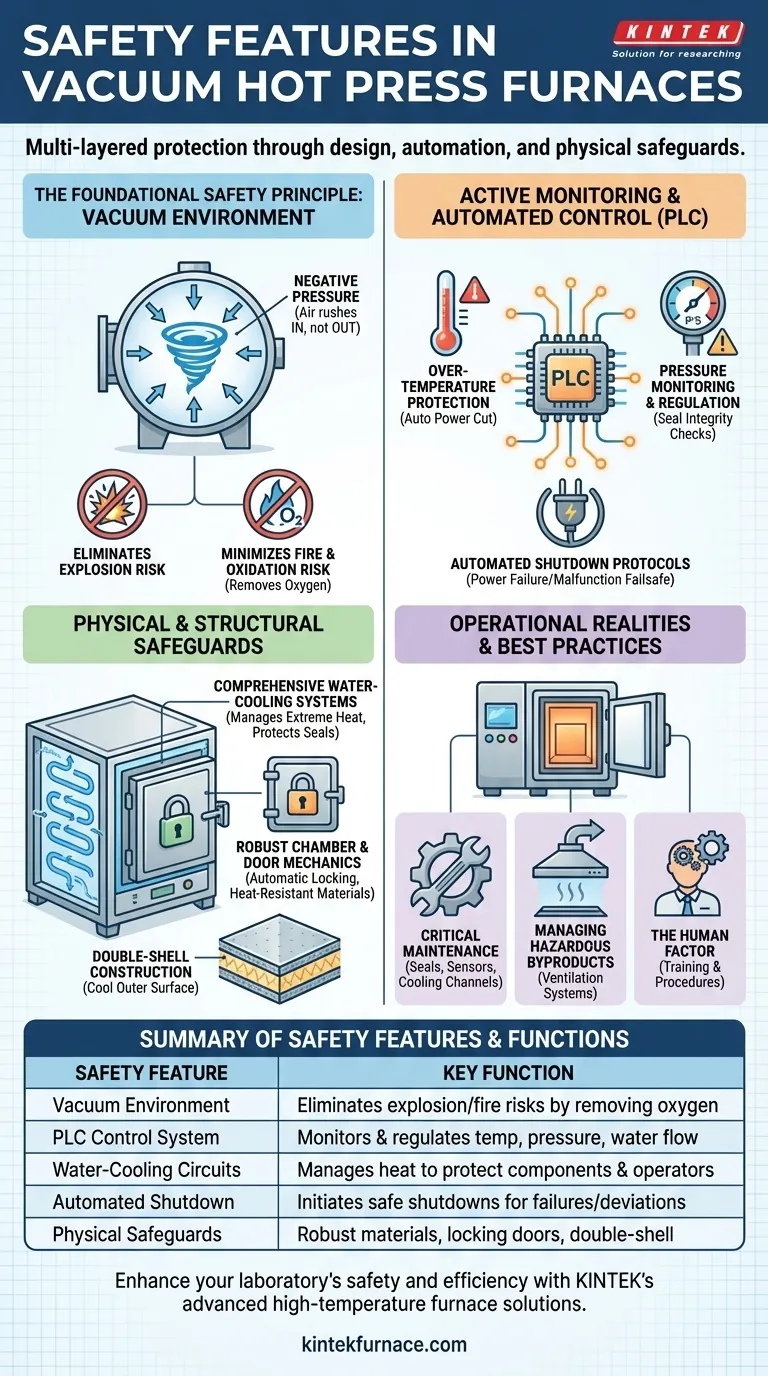

At their core, vacuum hot press furnaces are engineered with a multi-layered safety philosophy. These systems incorporate inherent design principles, active automated controls, and robust physical safeguards to protect operators, the equipment, and the materials being processed. Key features include the use of a vacuum to eliminate explosion and fire risks, comprehensive water-cooling circuits to manage extreme heat, and integrated PLC control systems that constantly monitor and regulate all critical parameters.

The safety of a vacuum hot press furnace does not rely on a single feature, but on a system of overlapping protections. The inherent safety of operating in a vacuum is bolstered by active, automated systems that monitor for and respond to any deviation from normal operating conditions.

The Foundational Safety Principle: The Vacuum Itself

The most fundamental safety feature is the vacuum environment. Unlike pressurized systems, which carry a risk of explosive failure, a vacuum furnace operates at negative pressure, which introduces- an entirely different and safer dynamic.

Eliminating Explosion Risk

Because the chamber is under negative pressure, a leak results in air rushing in rather than a violent explosion of hot gas and material rushing out. This design principle fundamentally eliminates the risk of a high-pressure rupture, which is a primary hazard in conventional pressure boilers.

Minimizing Fire and Oxidation Risk

Fire and rapid oxidation require oxygen. By removing ऑक्सीजन from the heating chamber, the vacuum environment drastically reduces the risk of workpieces or internal furnace components igniting at high temperatures.

Active Monitoring and Automated Control

A modern vacuum furnace is governed by a sophisticated control system, typically a Programmable Logic Controller (PLC), that acts as the central brain for all safety and operational functions.

The Role of the PLC Control System

The PLC integrates all sensors and safety mechanisms. It continuously monitors temperature, pressure, and cooling water flow, automatically making adjustments or initiating a safe shutdown if any parameter goes outside its predefined limits.

Over-Temperature Protection

Multiple temperature sensors (thermocouples) are placed in different heating zones. If the system detects a temperature exceeding the setpoint or a predefined safety limit, it will trigger an alarm and automatically cut power to the heating elements, preventing thermal runaway and damage.

Pressure Monitoring and Regulation

The system constantly monitors the vacuum level. It ensures the integrity of the chamber seal and can trigger an alarm or shutdown if the vacuum degrades. Some systems also include emergency pressure release valves as a final failsafe.

Automated Shutdown Protocols

Furnaces are equipped with power failure protection. If utility power is lost, the system initiates an orderly shutdown to protect the equipment. Similarly, dedicated circuit breakers and interlocks will immediately cut power if they detect electrical malfunctions.

Physical and Structural Safeguards

Beyond the vacuum and control system, the physical construction of the furnace is designed for safety and durability.

Comprehensive Water-Cooling Systems

An extensive network of water-cooling channels is built into the furnace shell, door, and power feedthroughs. This active cooling is critical for keeping the outer surfaces at a safe temperature for operators and protecting a O-ring seals and other heat-sensitive components from damage.

Robust Chamber and Door Mechanics

The furnace chamber is built from heat-resistant and corrosion-resistant materials to ensure a long service life. Doors feature automatic locking mechanisms that prevent them from being opened while the furnace is hot or not at atmospheric pressure. Many also include positive break safety switches that cut power to the heaters the moment the door is unlatched.

Double-Shell Construction and Insulation

Most vacuum furnaces use a double-shell design. The inner shell contains the heat and vacuum, while the water-cooled outer shell remains cool to the touch. High-efficiency insulation between these layers minimizes heat loss and further contributes to a low external surface temperature.

Common Pitfalls and Operational Realities

While these furnaces have robust safety systems, njihov effectiveness depends on proper use and maintenance.

The Criticality of Maintenance

Safety features are only reliable if they are maintained. Seals can wear out, sensors can drift out of calibration, and water channels can become clogged. A strict preventive maintenance schedule is non-negotiable for ensuring all safety systems function as designed.

Managing Hazardous Byproducts

When processing certain materials, volatile compounds or gases can be released. These can coat the inside of the furnace or, if not properly managed, present a hazard. In such cases, furnaces may need to be fitted with fume hoods or exhaust systems to safely vent and capture這些 byproducts.

The Human Factor

No automated system can replace a well-trained operator. Understanding the furnace's operation, recognizing alarm codes, and adhering to standard operating procedures are paramount for safe and effective use.

Making the Right Choice for Your Goal

Your role dictates which safety aspects you should prioritize.

- If you are an operator: Focus on thoroughly understanding pre-operation checks, alarm code meanings, and emergency shutdown procedures.

- If you are a facility manager or buyer: Prioritize systems with comprehensive PLC integration, detailed data logging, and robust post-sale maintenance support from the manufacturer.

- If you are a process engineer: Understand how safety interlocks, such as maximum temperature limits or cooling rates, define the operational boundaries for your thermal cycles.

A modern vacuum hot press furnace is a testament to how layers of automated and physical safety systems create a highly controlled and secure industrial environment.

Summary Table:

| Safety Feature | Key Function |

|---|---|

| Vacuum Environment | Eliminates explosion and fire risks by removing oxygen |

| PLC Control System | Monitors and regulates temperature, pressure, and water flow |

| Water-Cooling Circuits | Manages heat to protect components and operators |

| Automated Shutdown | Initiates safe shutdowns for power failures or parameter deviations |

| Physical Safeguards | Includes robust materials, locking doors, and double-shell construction |

Enhance your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique experimental needs. Our strong deep customization capability ensures precise protection and performance for diverse laboratories. Contact us today to discuss how our furnaces can safeguard your operations and deliver reliable results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability