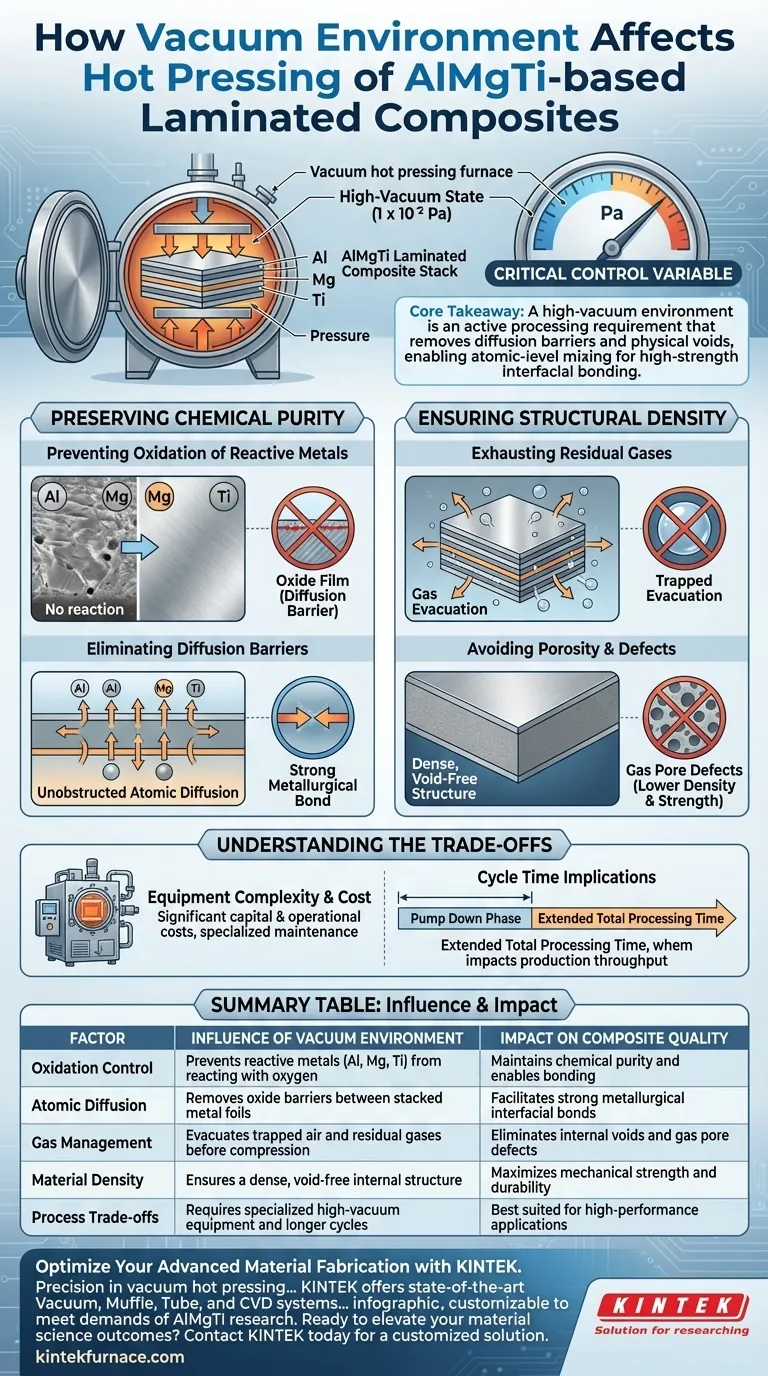

The vacuum environment acts as the critical control variable determines the structural success of AlMgTi-based laminated composites. By establishing a high-vacuum state (typically around $1 \times 10^{-2}$ Pa), the process prevents the catastrophic oxidation of highly reactive metal foils while simultaneously evacuating trapped gases that would otherwise compromise the material's density.

Core Takeaway A high-vacuum environment is not merely about cleanliness; it is an active processing requirement that removes diffusion barriers and physical voids. By preventing oxide film formation and exhausting residual gases, vacuum conditions enable the atomic-level mixing required for high-strength interfacial bonding.

Preserving Chemical Purity

Preventing Oxidation of Reactive Metals

Aluminum, magnesium, and titanium are highly reactive metals, particularly when exposed to the elevated temperatures required for hot pressing.

Without a vacuum, these metals would react instantly with atmospheric oxygen. The vacuum environment effectively isolates the raw materials, preventing the chemical degradation of the metal foils before bonding can occur.

Eliminating Diffusion Barriers

The formation of oxide films on metal surfaces acts as a wall, blocking the movement of atoms.

By maintaining a clean, oxide-free surface, the vacuum ensures unobstructed elemental diffusion channels. This allows atoms to migrate freely between layers, a necessary condition for creating a strong metallurgical bond between the aluminum, magnesium, and titanium interfaces.

Ensuring Structural Density

Exhausting Residual Gases

When metal foils are stacked prior to pressing, pockets of air and residual gases are inevitably trapped between the layers.

The vacuum environment evacuates these gases before the stack is compressed. This is a critical step that mechanical pressure alone cannot solve; without vacuum, pressure would simply trap these gases inside the composite.

Avoiding Porosity and Defects

Trapped gases that remain during the heating phase result in gas pore defects or voids within the final composite.

These voids significantly reduce the density and mechanical strength of the material. A vacuum environment is the only reliable method to ensure a dense, void-free internal structure capable of handling stress.

Understanding the Trade-offs

Equipment Complexity and Cost

While vacuum hot pressing yields superior material properties, it introduces significant capital and operational costs.

High-vacuum furnaces are complex to maintain and operate compared to standard atmosphere presses. This requires specialized training and rigorous maintenance schedules to ensure seals and pumps function correctly.

Cycle Time Implications

Achieving high vacuum levels (e.g., $1 \times 10^{-2}$ Pa) extends the total processing time.

The system must be pumped down effectively before heating begins to prevent oxidation during the ramp-up phase. This impacts production throughput, making the process better suited for high-performance applications rather than high-volume commodity manufacturing.

Making the Right Choice for Your Goal

To maximize the quality of your AlMgTi composites, align your process controls with your specific performance requirements:

- If your primary focus is Interfacial Bond Strength: Ensure your vacuum level is sufficient to prevent any oxidation, as even microscopic oxide layers will severely inhibit atomic diffusion.

- If your primary focus is Material Density: Prioritize the "pump down" phase before applying heat or pressure to fully evacuate interlaminar gases and prevent porosity.

Ultimately, the vacuum is not just an environment; it is the invisible tool that enables the physics of solid-state bonding.

Summary Table:

| Factor | Influence of Vacuum Environment | Impact on Composite Quality |

|---|---|---|

| Oxidation Control | Prevents reactive metals (Al, Mg, Ti) from reacting with oxygen | Maintains chemical purity and enables bonding |

| Atomic Diffusion | Removes oxide barriers between stacked metal foils | Facilitates strong metallurgical interfacial bonds |

| Gas Management | Evacuates trapped air and residual gases before compression | Eliminates internal voids and gas pore defects |

| Material Density | Ensures a dense, void-free internal structure | Maximizes mechanical strength and durability |

| Process Trade-offs | Requires specialized high-vacuum equipment and longer cycles | Best suited for high-performance applications |

Optimize Your Advanced Material Fabrication with KINTEK

Precision in vacuum hot pressing is the difference between a failed bond and a high-performance composite. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, Muffle, Tube, and CVD systems, all fully customizable to meet the rigorous demands of AlMgTi-based research and production. Whether you need to eliminate atmospheric oxidation or achieve maximum material density, our lab high-temperature furnaces provide the control you need.

Ready to elevate your material science outcomes? Contact KINTEK today for a customized solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is a vacuum hot-pressing furnace essential for graphite flake/Al composites? Achieving High Density & Performance

- What are the advantages of using a Spark Plasma Sintering (SPS) system for UHTCs? Master Rapid Densification

- Why is a Vacuum Hot Press (VHP) furnace more suitable for preparing ODS alloys? Superior Uniformity & Density

- What are the classifications of hot pressing sintering furnaces based on the use environment? Explore Types for Optimal Material Processing

- What is Vacuum Hot Pressing used for in ceramic and powder metal targets? Achieve Superior Density and Purity

- What are the technical advantages of using Pulsed Current Sintering (PCS) for Ag2S1-xTex? Optimize Your Microstructure

- What physical conditions are provided by the heating plate and high-voltage DC power supply? Mastery of Anodic Bonding

- How does temperature control precision affect CsPbBr3-CaF2 ceramic quality? Master the Cold Sintering Process