Spark Plasma Sintering (SPS) fundamentally outperforms traditional methods for Ultra-High Temperature Ceramics (UHTCs) by utilizing pulsed electric current to generate heat directly within the material and mold. This internal heating mechanism, combined with simultaneous uniaxial pressure (typically 50 MPa), allows for rapid densification at significantly lower temperatures—such as 1900°C—and over much shorter durations than conventional external heating allows.

Core Takeaway The primary advantage of SPS is its ability to decouple densification from grain growth. By applying direct Joule heating and mechanical pressure, SPS achieves full density so rapidly that the material's microstructure does not have time to coarsen, preserving fine grain sizes and enabling advanced chemical features that improve performance.

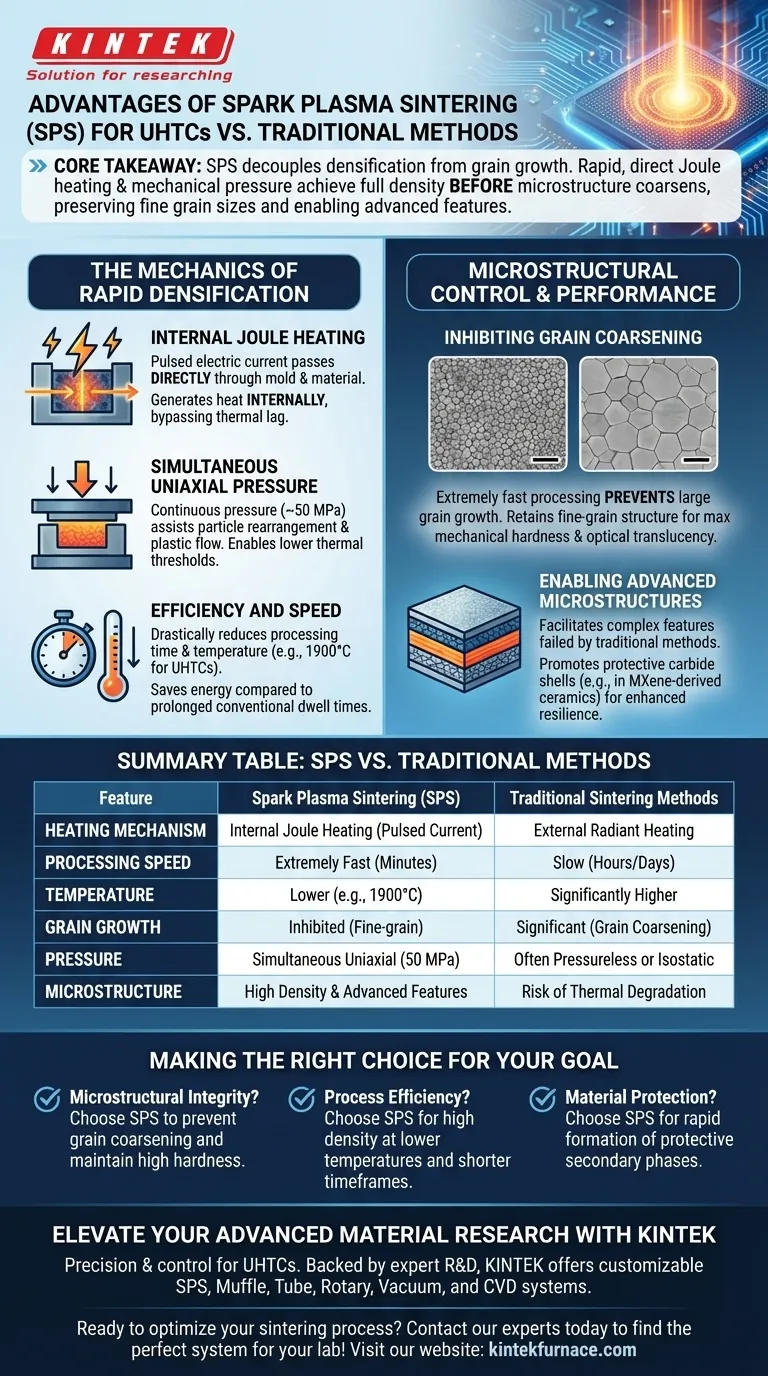

The Mechanics of Rapid Densification

Internal Joule Heating

Unlike traditional furnaces that heat the environment around the sample, SPS passes pulsed electric current directly through the mold and the material.

This generates Joule heat internally, resulting in extremely fast heating rates that bypass the thermal lag associated with radiant heating.

Simultaneous Mechanical Pressure

The system applies a continuous uniaxial pressure, often around 50 MPa, during the heating phase.

This mechanical force assists in particle rearrangement and plastic flow, allowing the material to densify at lower thermal thresholds than would be required in pressureless sintering.

Efficiency and Speed

The combination of internal heating and pressure drastically reduces the total processing time.

Sintering can be successfully completed at lower temperatures (e.g., 1900°C for specific UHTC compositions), saving energy and reducing cycle times compared to the prolonged dwell times of conventional methods.

Microstructural Control and Performance

Inhibiting Grain Coarsening

One of the critical challenges in sintering UHTCs is that high temperatures usually cause grains to grow large, which weakens the material.

Because SPS is so fast, it effectively inhibits the growth of grains (such as ZrB2 or ZnS). This retention of a fine-grain structure is essential for maximizing mechanical hardness and, in some cases, optical translucency.

Enabling Advanced Microstructures

The unique processing environment of SPS facilitates the development of complex microstructural features that traditional methods may fail to produce.

For instance, in specific UHTC composites, the process promotes the formation of a protective carbide shell derived from MXene components, which further enhances the material's resilience.

Understanding the Trade-offs

Geometric Constraints

The reliance on uniaxial pressure implies specific physical limitations regarding the shape of the ceramic being produced.

Because the pressure is applied in a single direction via a mold, producing complex, non-symmetrical geometries is more difficult than with pressureless methods.

Material-Current Interaction

Success depends on the material's ability to handle the pulsed current and the interaction with the mold.

The generation of Joule heat requires the current to pass through the assembly effectively; if the material assembly is not optimized for this current flow, heating may be non-uniform.

Making the Right Choice for Your Goal

While SPS is a powerful tool, its application should align with your specific material requirements.

- If your primary focus is Microstructural Integrity: SPS is the superior choice to prevent grain coarsening and maintain high hardness in materials like ZrB2 or ZnS.

- If your primary focus is Process Efficiency: SPS offers the distinct advantage of achieving high density at lower temperatures (1900°C) and significantly shorter timeframes.

- If your primary focus is Material Protection: The rapid processing of SPS facilitates the formation of protective secondary phases, such as carbide shells in MXene-derived ceramics.

By leveraging the direct energy transfer of Spark Plasma Sintering, you achieve a density-to-structure ratio that is virtually impossible with conventional heating methods.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Sintering Methods |

|---|---|---|

| Heating Mechanism | Internal Joule Heating (Pulsed Current) | External Radiant Heating |

| Processing Speed | Extremely Fast (Minutes) | Slow (Hours/Days) |

| Temperature | Lower (e.g., 1900°C for UHTCs) | Significantly Higher |

| Grain Growth | Inhibited (Fine-grain structure) | Significant (Grain coarsening) |

| Pressure | Simultaneous Uniaxial (50 MPa) | Often Pressureless or Isostatic |

| Microstructure | High Density & Advanced Features | Risk of Thermal Degradation |

Elevate Your Advanced Material Research with KINTEK

Precision and control are non-negotiable when working with Ultra-High Temperature Ceramics (UHTCs). Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art SPS systems, Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your lab's unique high-temperature requirements.

Whether you need to inhibit grain growth or accelerate densification cycles, our high-temp furnace solutions deliver the efficiency and performance your research demands.

Ready to optimize your sintering process? Contact our experts today to find the perfect system for your lab!

Visual Guide

References

- Srinivasa Kartik Nemani, Babak Anasori. Ti <sub>3</sub> C <sub>2</sub> T <i> <sub>x</sub> </i> MXene‐Zirconium Diboride Based Ultra‐High Temperature Ceramics. DOI: 10.1002/advs.202500487

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What functions does a graphite mold serve during ZnS vacuum hot pressing? Optimize Density and Optical Purity

- What advantages does a vacuum press offer in material processing? Achieve Superior Density and Purity

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Cu2Se Densification and Thermoelectric Performance

- Why are graphite molds necessary during the hot pressing sintering process of Fe-Cu-Ni-Sn-VN? Essential Sintering Tools

- How does a vacuum hot press sintering furnace mitigate copper sintering swelling? Solve Fe-Cu Expansion Issues

- What is the function of the low-pressure debinding stage in a vacuum hot press? Ensure SiC Fiber Alignment & Integrity

- How does temperature control in a vacuum hot pressing furnace influence the interface quality of Ti-Al composites?

- Why is an industrial hot press critical for lunar ceramic components? Achieve Maximum Density and Impact Resistance