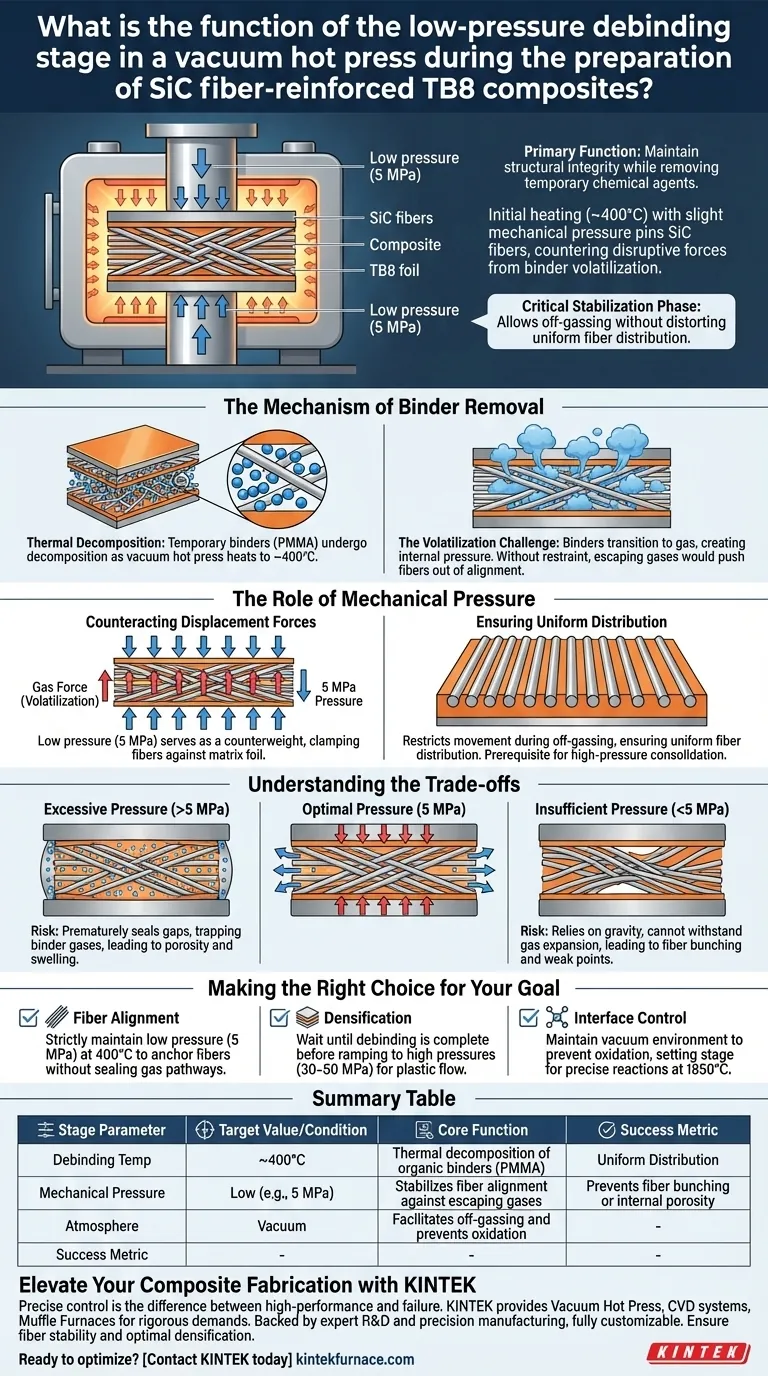

The primary function of the low-pressure debinding stage is to maintain the structural integrity of the composite while removing temporary chemical agents. During the initial heating phase (approximately 400°C), a slight mechanical pressure (e.g., 5 MPa) is applied to pin SiC fibers in place, countering the disruptive forces caused by the volatilization of binders like PMMA.

The low-pressure stage acts as a critical stabilization phase; it allows essential off-gassing to occur without permitting the turbulence of escaping gases to distort the uniform distribution of the reinforcement fibers.

The Mechanism of Binder Removal

Thermal Decomposition

The fabrication process relies on temporary binders, such as PMMA (polymethyl methacrylate), to initially fix the SiC fibers within the titanium matrix.

As the vacuum hot press heats the assembly to the 400°C range, these organic binders undergo thermal decomposition.

The Volatilization Challenge

When binders decompose, they transition from a solid state to gas.

This phase change creates internal pressure and gas flow within the composite preform. Without restraint, the force of these escaping gases would be sufficient to push the fibers out of alignment, ruining the material's homogeneity.

The Role of Mechanical Pressure

Counteracting Displacement forces

The application of a specific, low pressure (5 MPa) serves as a mechanical counterweight to the volatilization process.

This pressure is high enough to physically clamp the fibers against the matrix foil, preventing them from "floating" or shifting as the binder turns to gas.

Ensuring Uniform Distribution

By restricting movement during the off-gassing phase, the process ensures the fiber distribution remains uniform.

This uniformity is a prerequisite for the subsequent high-pressure consolidation stages, where the matrix will plastically flow to bond with the fibers.

Understanding the Trade-offs

The Risk of Excessive Pressure

It is critical not to confuse the debinding pressure (5 MPa) with the consolidation pressure (30–50+ MPa) used later.

Applying excessive pressure during the debinding stage could prematurely seal the gaps between fibers and the matrix. This would trap the volatilized binder gases inside the composite, leading to internal porosity and causing the material to swell or delaminate later.

The Risk of Insufficient Pressure

Conversely, applying zero pressure during this stage relies entirely on gravity and friction to hold the architecture together.

This is rarely sufficient to withstand the expansion of escaping gases, leading to fiber bunching or gaps. This structural disorder results in distinct weak points in the final composite.

Making the Right Choice for Your Goal

To optimize the vacuum hot pressing process for SiC/TB8 composites, align your pressure parameters with your specific fabrication stage:

- If your primary focus is Fiber Alignment: strictly maintain the low-pressure setting (e.g., 5 MPa) during the 400°C ramp to anchor fibers without sealing gas pathways.

- If your primary focus is Densification: Wait until the debinding phase is fully complete before ramping to high pressures (30–50 MPa) to force plastic flow of the TB8 foil.

- If your primary focus is Interface Control: Ensure the vacuum environment is maintained throughout debinding to prevent oxidation, setting the stage for the precise chemical reaction required later at higher temperatures (1850°C).

Successful composite fabrication requires treating debinding not just as a cleaning step, but as a structural preservation phase.

Summary Table:

| Stage Parameter | Target Value/Condition | Core Function |

|---|---|---|

| Debinding Temp | ~400°C | Thermal decomposition of organic binders (PMMA) |

| Mechanical Pressure | Low (e.g., 5 MPa) | Stabilizes fiber alignment against escaping gases |

| Atmosphere | Vacuum | Facilitates off-gassing and prevents oxidation |

| Success Metric | Uniform Distribution | Prevents fiber bunching or internal porosity |

Elevate Your Composite Fabrication with KINTEK

Precise control over the debinding and consolidation stages is the difference between a high-performance composite and material failure. KINTEK provides industry-leading Vacuum Hot Press systems, CVD systems, and Muffle Furnaces designed to handle the rigorous demands of SiC fiber-reinforced material production.

Backed by expert R&D and precision manufacturing, our high-temperature lab furnaces are fully customizable to meet your unique research and production needs. Ensure fiber stability and optimal densification in every cycle.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your custom solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- What are the technical advantages of a Spark Plasma Sintering (SPS) system? Achieve Superior TiB2 Ceramic Performance

- What is the purpose of using a hydrogen-argon mixture for hot-pressing SnSe? Enhance Thermoelectric zT Efficiency

- What types of materials can be processed using vacuum hot press furnaces? Ideal for Advanced Ceramics and Metals

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication

- In which industries is the vacuum press commonly used? Essential for Aerospace, Medical, and Electronics

- Why is a Vacuum Hot Press Sintering (VHPS) furnace preferred for AlxCoCrFeNi high-entropy alloys? Achieve 99% Density

- How does the pressurization system of a vacuum hot press affect SiC/TB8 composites? Optimize Matrix Densification