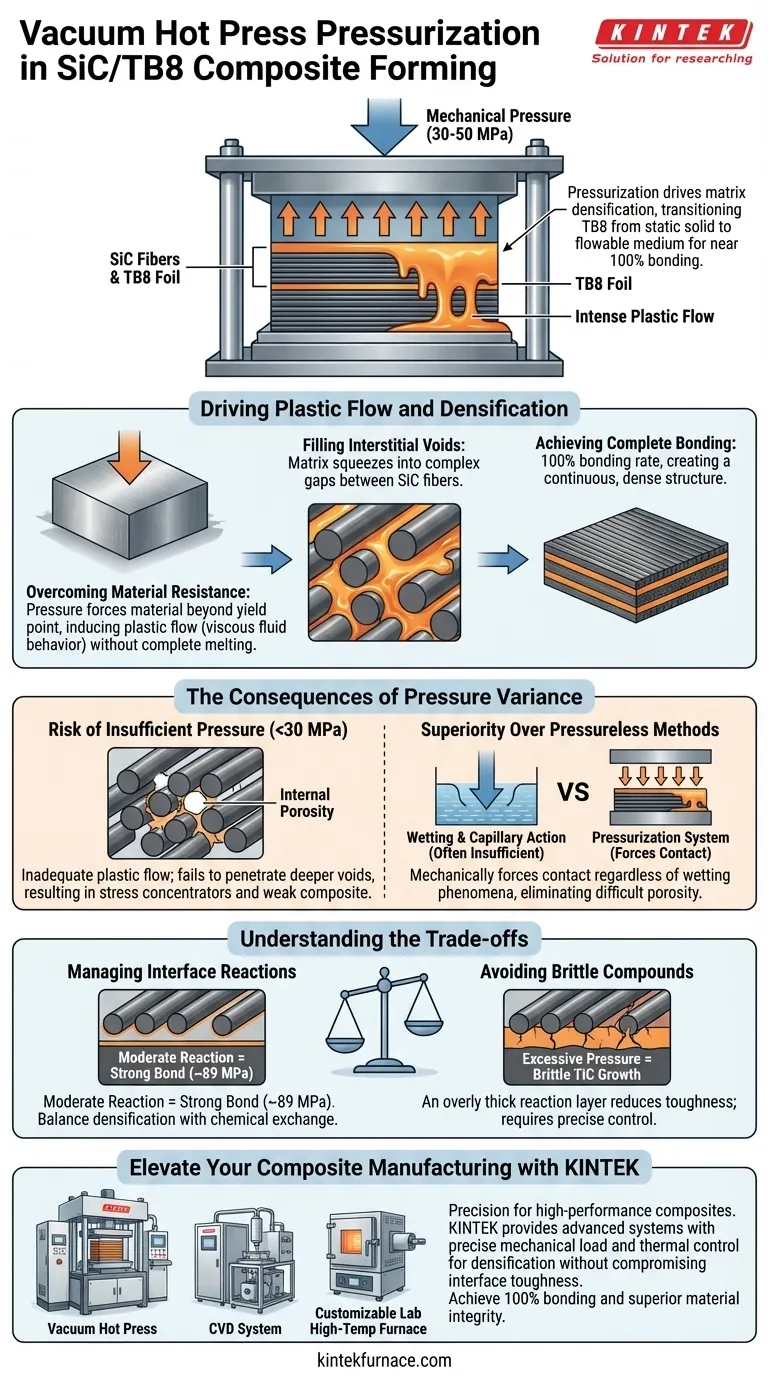

The pressurization system serves as the primary driver for matrix densification. It applies a specific mechanical load, typically between 30 and 50 MPa, to force the TB8 foil into a state of intense plastic flow. This physical deformation compels the matrix material to squeeze into and fill the microscopic voids between SiC fibers, which is impossible to achieve through passive heating alone.

The application of external mechanical pressure is the defining factor that transitions the TB8 matrix from a static solid into a flowable medium, ensuring it fully encapsulates the fibers to achieve a near 100% bonding rate.

Driving Plastic Flow and Densification

Overcoming Material Resistance

Under normal conditions, the TB8 foil maintains its structural integrity. The vacuum hot press applies mechanical pressure that forces the material beyond its yield point.

This induces intense plastic flow, causing the metal to behave more like a viscous fluid. This transformation is necessary to manipulate the matrix shape without melting it completely.

Filling Interstitial Voids

The primary goal of this deformation is geometric adaptation. The SiC fibers create a complex network of gaps and voids that must be filled.

The pressurized flow forces the TB8 matrix into these interstitial spaces. It effectively "squeezes" the alloy into every available crevice between the fibers.

Achieving Complete Bonding

Success is measured by the bonding rate. When the pressure forces the matrix to coat the fibers completely, a 100% bonding rate can be achieved.

This creates a continuous, dense composite structure. Without this mechanical force, the matrix would merely sit atop the fibers rather than integrating with them.

The Consequences of Pressure Variance

The Risk of Insufficient Pressure

If the pressure applied is below the optimal range (e.g., lower than 30 MPa), the plastic flow will be inadequate. The matrix will fail to penetrate the deeper voids between fibers.

This results in internal porosity. These air gaps act as stress concentrators, significantly weakening the final composite.

Superiority Over Pressureless Methods

Pressureless sintering relies on wetting and capillary action, which is often insufficient for these materials. Interfaces often exhibit non-wetting phenomena that resist passive bonding.

The pressurization system mechanically forces contact regardless of wetting properties. This eliminates the porosity that is notoriously difficult to remove in pressureless processes.

Understanding the Trade-offs

Managing Interface Reactions

While pressure creates necessary physical contact, it also facilitates chemical reactions. The close contact between the Titanium-based matrix and SiC fibers initiates a chemical exchange.

You must balance the need for densification with the risk of over-reaction. A moderate reaction creates a strong bond (e.g., ~89 MPa strength).

Avoiding Brittle Compounds

Excessive pressure or holding times can lead to adverse effects. If the interface reaction is too aggressive, it promotes the growth of brittle compounds like Titanium Carbide (TiC).

An overly thick reaction layer reduces the material's toughness. Therefore, the pressurization must be precise—enough to densify, but controlled to limit brittle phase formation.

Making the Right Choice for Your Goal

To optimize the forming of SiC/TB8 composites, you must align your process parameters with your specific structural requirements.

- If your primary focus is Eliminating Porosity: Ensure pressure is maintained between 30-50 MPa to guarantee the TB8 foil undergoes sufficient plastic flow to fill all fiber voids.

- If your primary focus is Interface Toughness: Strictly regulate the pressure and holding time (e.g., 40 MPa for 1 hour) to prevent the reaction layer from becoming too thick and brittle.

Precise control of the pressurization system allows you to achieve a fully dense matrix while maintaining the ductility required for high-performance applications.

Summary Table:

| Parameter | Influence on SiC/TB8 Matrix | Effect on Composite Quality |

|---|---|---|

| Pressure < 30 MPa | Inadequate plastic flow | Internal porosity and weak bonding |

| Pressure 30-50 MPa | Intense plastic flow & filling | Near 100% bonding rate & high density |

| Optimal Load Time | Controlled interface reaction | High shear strength (~89 MPa) |

| Excessive Pressure | Growth of brittle compounds | Increased TiC layer & reduced toughness |

Elevate Your Composite Manufacturing with KINTEK

Precision is the difference between a high-performance composite and material failure. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Vacuum Hot Press systems, CVD systems, and customizable lab high-temp furnaces designed to meet the rigorous demands of SiC/TB8 processing.

Our equipment ensures the precise mechanical load and thermal control necessary to drive matrix densification without compromising interface toughness. Whether you need a standard solution or a custom-engineered furnace for unique research needs, our team is ready to help you achieve 100% bonding rates and superior material integrity.

Ready to optimize your lab's thermal processing? Contact us today to speak with a specialist!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does a vacuum hot press machine improve material properties? Achieve Superior Strength and Purity

- How does a hot pressing (HP) system achieve full densification? Achieve 100% Density in Ti-5Al-4W-2Fe Alloys

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- How does the high vacuum environment provided by a vacuum hot press furnace influence the properties of Cu/rGO composites? Achieve Superior Composite Performance

- What is hot pressing and how does it work? Achieve Superior Material Density and Strength

- What functions do graphite molds perform during vacuum hot press sintering? Discover their active role in densification

- What role do high-strength graphite molds play during SPS? Boost Mo-Cr-Y Composite Densification

- How does a vacuum press work? Harness Atmospheric Pressure for Perfect Clamping