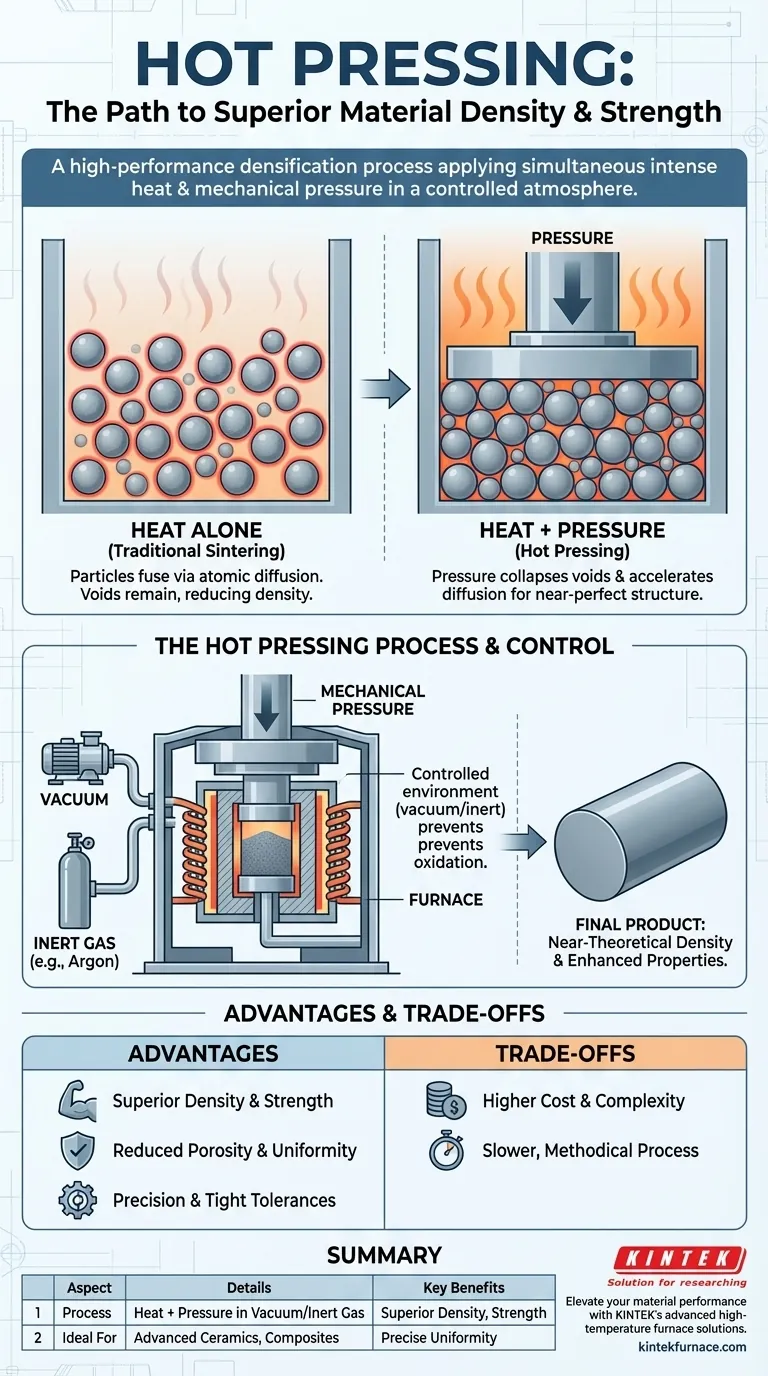

In materials manufacturing, hot pressing is a high-performance densification process that simultaneously applies intense heat and mechanical pressure to a material. This combination is typically performed in a vacuum or a controlled inert gas atmosphere. By applying force during the heating (sintering) phase, the process physically eliminates internal voids, resulting in a final product with superior density, strength, and integrity.

Hot pressing overcomes the limitations of traditional heating methods by using pressure to force material particles together. This creates a final product that is significantly denser and stronger than what could be achieved with heat alone, enabling the production of advanced materials with near-perfect structures.

The Core Principle: Why Heat and Pressure Work Together

Hot pressing is fundamentally about achieving a level of material consolidation that is not possible through simple heating or pressing alone.

The Limitation of Heat Alone

In traditional sintering, a powdered material is heated to a high temperature, just below its melting point. This thermal energy allows atoms to diffuse across the boundaries of the particles, causing them to bond and fuse together.

However, this process often leaves behind small, trapped pores or voids within the material. These imperfections reduce the overall density and can become points of failure, compromising the material's mechanical strength.

How Pressure Transforms the Process

By introducing high mechanical pressure simultaneously with the heat, hot pressing actively forces the material particles into intimate contact. This pressure has two primary effects.

First, it physically collapses the voids that would otherwise be trapped. Second, it accelerates the atomic diffusion and plastic deformation that bond the particles, allowing the material to densify much more quickly and completely.

A Look Inside the Hot Pressing Process

The effectiveness of hot pressing comes from its precise control over three critical variables: heat, pressure, and atmosphere.

The Key Components

The process takes place inside a specialized piece of equipment that combines a high-temperature furnace with a powerful hydraulic or mechanical press. The material, often in powder form, is placed into a die, which is then heated while the press applies a constant force.

Preventing Oxidation with a Controlled Environment

Most high-performance materials, such as advanced ceramics or metal alloys, will rapidly oxidize or degrade when exposed to air at high temperatures. To prevent this, hot pressing is conducted in either a vacuum or under a positive pressure of an inert gas like argon.

This controlled atmosphere ensures the chemical purity and structural integrity of the final component.

Achieving Near-Theoretical Density

The ultimate goal of hot pressing is to produce a billet or component with a density that is as close as possible to the material's theoretical maximum. By effectively eliminating porosity, the process yields a monolithic structure with vastly improved properties.

Understanding the Trade-offs and Advantages

While powerful, hot pressing is a specialized technique with a distinct set of benefits and limitations.

Advantage: Superior Material Properties

The primary benefit is the creation of materials with exceptional density, reduced porosity, and significantly enhanced mechanical strength, hardness, and wear resistance. This is non-negotiable for many demanding applications.

Advantage: Precision and Uniformity

The combination of controlled heat and pressure ensures uniform bonding and material flow. This results in high-quality components with minimal internal stress and deformation, holding tight dimensional tolerances.

Limitation: Cost and Complexity

Hot pressing equipment is more complex and expensive than standard sintering furnaces. The process is also typically slower and more methodical, making it better suited for high-value components rather than high-volume, low-cost manufacturing.

Making the Right Choice for Your Goal

Hot pressing is not a universal solution, but it is an indispensable tool when performance is the primary driver.

- If your primary focus is maximum density and strength: Hot pressing is the ideal choice for creating components with near-zero porosity and superior mechanical properties, especially for advanced ceramics and composites.

- If you are working with oxygen-sensitive materials: The controlled vacuum or inert atmosphere of hot pressing is essential to prevent chemical degradation during high-temperature processing.

- If your primary focus is high-volume, low-cost production: You may need to evaluate simpler methods like conventional sintering, accepting a potential trade-off in final material quality.

Ultimately, hot pressing provides a powerful method for engineering materials to their absolute performance limits.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Simultaneous application of heat and pressure in a vacuum or inert atmosphere |

| Key Benefits | Superior density, enhanced strength, reduced porosity, precise uniformity |

| Ideal For | Advanced ceramics, composites, oxygen-sensitive materials |

| Limitations | Higher cost, slower process, complex equipment |

Elevate your material performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored hot pressing systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior density and strength in materials like ceramics and composites. Contact us today to discuss how we can optimize your process and achieve unparalleled results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure