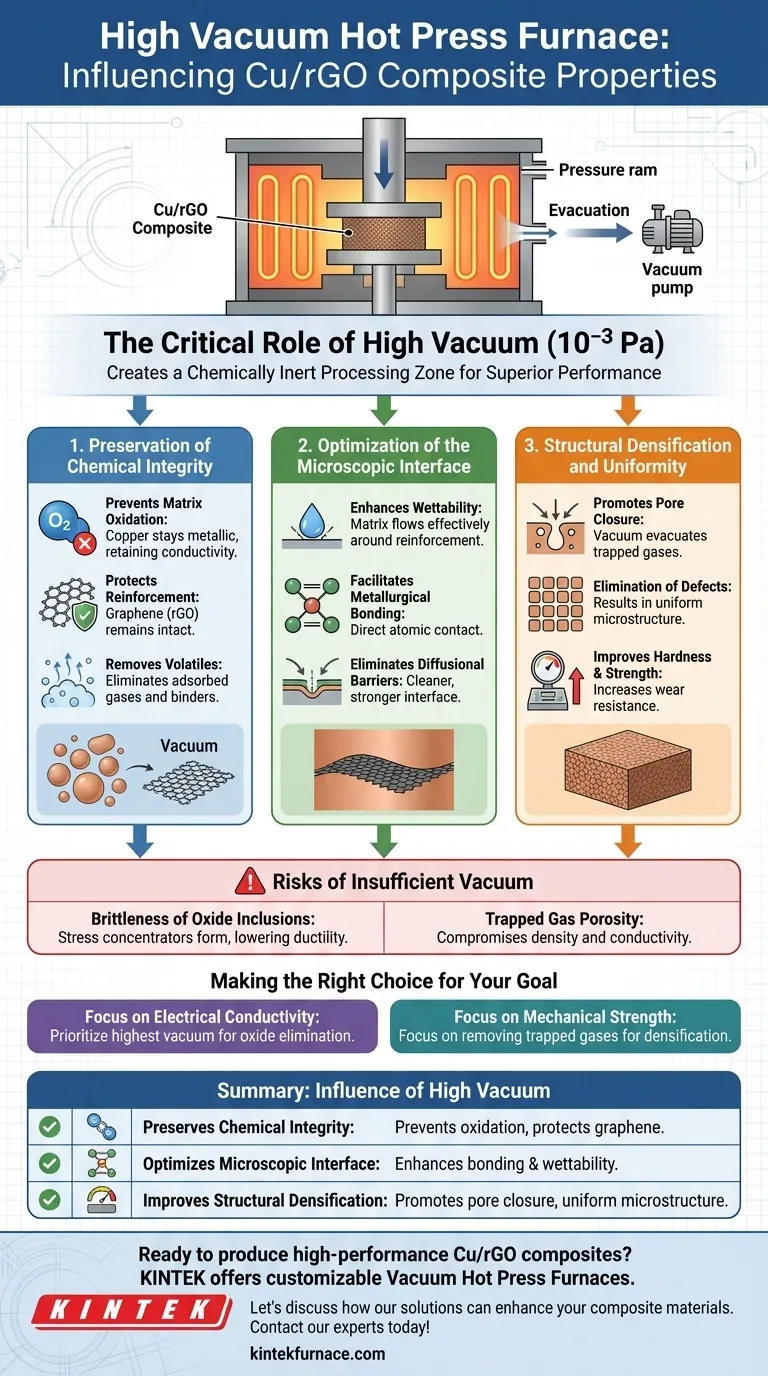

The high vacuum environment acts as a critical purification mechanism during the sintering of Cu/rGO composites, fundamentally determining the material's final performance limits. By reducing the pressure to levels such as $10^{-3}$ Pa, the furnace effectively eliminates oxygen and volatile impurities, preventing the formation of insulating copper oxide films and protecting the graphene reinforcement from thermal degradation.

Core Insight: The primary value of the vacuum environment is not just pressure application, but the creation of a chemically inert processing zone. This allows for atomic-level diffusion between the copper matrix and graphene sheets without the interference of oxide layers or gas pockets, resulting in a composite that maximizes both electrical conductivity and mechanical strength.

1. Preservation of Chemical Integrity

The presence of oxygen at sintering temperatures (often $1150^{\circ}\text{C}$ to $1250^{\circ}\text{C}$) is the single greatest threat to Cu/rGO composite quality.

Prevention of Matrix Oxidation

Copper is highly susceptible to surface oxidation. A high vacuum environment drastically lowers the oxygen partial pressure, preventing the copper particles from forming copper oxide films. This ensures the metallic matrix retains its intrinsic electrical and thermal conductivity.

Protection of the Reinforcement Phase

Graphene (rGO) is vulnerable to degradation and oxidation at high temperatures. The vacuum environment shields the graphene structure, ensuring it remains intact to perform its role as a reinforcement agent.

Removal of Volatile Impurities

Raw materials often contain adsorbed gases (water vapor, nitrogen) or residual binders (waxes). The vacuum facilitates the extraction of these volatiles during the initial heating stages, preventing them from reacting with the copper matrix.

2. Optimization of the Microscopic Interface

The performance of a composite is defined by how well the matrix grips the reinforcement. Vacuum conditions are essential for optimizing this boundary.

Enhancing Wettability

By purifying the powder surfaces, the vacuum improves the wettability between the copper and the graphene. A clean surface allows the metal matrix to flow more effectively around the reinforcement phase.

Facilitating Metallurgical Bonding

The absence of brittle oxide inclusions allows for true metallurgical bonding between particles. This direct atomic contact significantly increases the interfacial bonding strength, reducing the likelihood of delamination under stress.

Elimination of Diffusional Barriers

Oxides and impurities act as barriers to atomic diffusion. By removing these, the vacuum promotes a cleaner, stronger microscopic interface, which is critical for transferring load and electrons between the copper and graphene.

3. Structural Densification and Uniformity

Beyond chemistry, the vacuum environment plays a physical role in the consolidation of the material.

Promoting Pore Closure

Residual gases trapped in interstitial spaces can prevent full densification. The vacuum continuously evacuates these gases, preventing the formation of closed pores and allowing the material to achieve near-theoretical density.

Elimination of Defects

The combination of vacuum and pressure aids in eliminating structural defects. This results in a uniform microstructure, which directly translates to improved hardness, compressive strength, and wear resistance.

Understanding the Trade-offs: The Risks of Insufficient Vacuum

While a high vacuum is beneficial, relying on it requires precise control. Understanding the consequences of vacuum failure is as important as understanding its benefits.

The Brittleness of Oxide Inclusions

If the vacuum level is insufficient (e.g., rising above the critical threshold for copper oxidation), oxide inclusions will form. These inclusions act as stress concentrators, making the final composite brittle and significantly lowering its ductility.

Trapped Gas Porosity

Failure to maintain a vacuum during the early stages of sintering can trap volatile binders inside the compact. This leads to internal porosity that pressure alone cannot fix, permanently compromising the material’s density and conductivity.

Making the Right Choice for Your Goal

The specific influence of the vacuum environment supports different engineering objectives. Use this guide to align your process with your end goals.

- If your primary focus is Electrical Conductivity: Prioritize the highest possible vacuum ($10^{-3}$ Pa or better) to ensure absolute elimination of copper oxide films, which are electrical insulators.

- If your primary focus is Mechanical Strength: Focus on the vacuum's ability to remove adsorbed gases to maximize pore closure and densification, ensuring high hardness and wear resistance.

The high vacuum environment is not merely a setting on the furnace; it is the active agent that enables the compatibility of copper and graphene, transforming a mixture of powders into a high-performance, cohesive composite.

Summary Table:

| Influence of High Vacuum | Key Benefit for Cu/rGO Composites |

|---|---|

| Preserves Chemical Integrity | Prevents copper oxidation & protects graphene from degradation. |

| Optimizes Microscopic Interface | Enhances wettability & facilitates strong metallurgical bonding. |

| Improves Structural Densification | Promotes pore closure & eliminates defects for uniform microstructure. |

Ready to produce high-performance Cu/rGO composites with superior electrical and mechanical properties?

The precise high vacuum environment is critical for your success. Backed by expert R&D and manufacturing, KINTEK offers customizable Vacuum Hot Press Furnaces and other lab high-temp systems (including Muffle, Tube, Rotary, and CVD furnaces) to meet your unique research and production needs.

Let's discuss how our solutions can enhance your composite materials. Contact our experts today!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the vacuum press contribute to material property improvement? Achieve Denser, Purer Materials for Superior Performance

- What factors should be considered when choosing a vacuum press for metalworking? Optimize Your Investment for Precision and Efficiency

- What is the role of sacrificial inserts in the Spark Plasma Sintering (SPS) process? Master Complex Geometry Design

- What roles do high-strength graphite molds play during the hot-pressing sintering of TiAl-SiC composites?

- How does the uniaxial pressure applied by a vacuum hot press furnace affect the microstructure of ZrC-SiC materials?

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What are the technical advantages of using Pulsed Current Sintering (PCS) for Ag2S1-xTex? Optimize Your Microstructure

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials