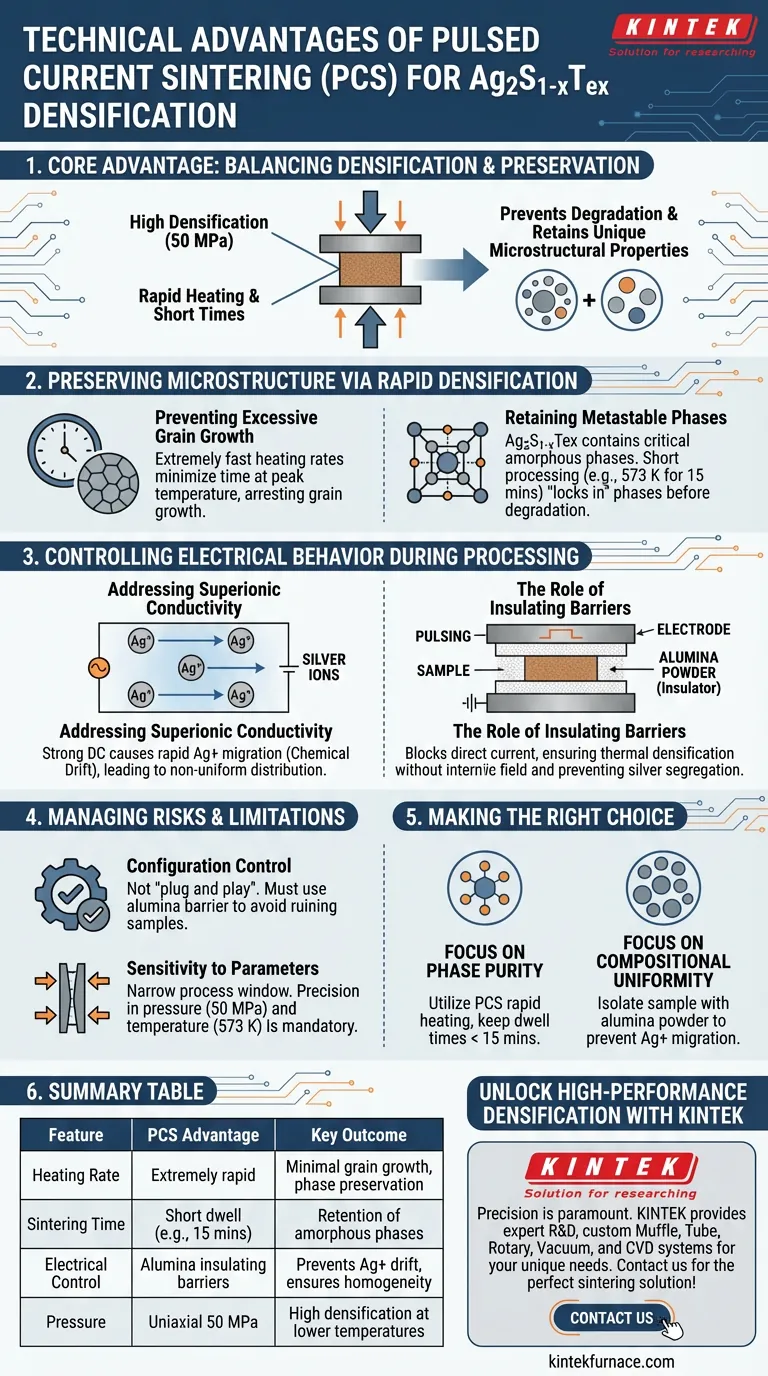

The primary technical advantage of Pulsed Current Sintering (PCS) for Ag2S1-xTex lies in its ability to achieve high densification through extremely rapid heating rates and short processing times. By applying direct pulsed current alongside uniaxial pressure (typically 50 MPa), PCS consolidates the material quickly, preventing the degradation of its unique microstructural properties.

The core value of PCS for this material is the balance between densification and preservation. It generates the necessary heat and pressure to solidify the sample without exposing it to the prolonged thermal cycles that destroy metastable phases and induce chemical segregation.

Preserving Microstructure via Rapid Densification

Preventing Excessive Grain Growth

Traditional sintering methods often require long "soak" times at high temperatures. This prolonged exposure allows crystal grains to grow excessively large, which can degrade mechanical and electrical properties.

PCS circumvents this by utilizing extremely fast heating rates. By minimizing the time the material spends at peak temperature, the technique effectively arrests grain growth, maintaining a fine microstructure.

Retaining Metastable Phases

Ag2S1-xTex samples contain metastable amorphous phases that are critical to their performance. These phases are thermodynamically unstable and will crystallize or transform if held at high temperatures for too long.

The short densification times inherent to PCS—such as holding at 573 K for just 15 minutes—are crucial here. This rapid processing window "locks in" the amorphous phases before they can degrade.

Controlling Electrical Behavior During Processing

Addressing Superionic Conductivity

A unique challenge with Ag2S1-xTex is that the silver ions (Ag+) possess superionic conductivity. If a strong direct current flows directly through the sample, these ions will migrate rapidly under the electric field.

This migration creates a "chemical drift," leading to a non-uniform distribution of silver throughout the material. This results in inconsistent electrical and mechanical properties across the final part.

The Role of Insulating Barriers

To leverage the heat of PCS without triggering ion migration, the setup requires specific modification. The top and bottom of the sample are covered with insulating alumina powder.

Ensuring Chemical Homogeneity

This insulation blocks the direct passage of pulsed current through the Ag2S1-xTex material itself. Instead, the heat is generated externally or indirectly, ensuring the sample densifies thermally without being subjected to the internal electric field that drives silver segregation.

Managing Process Risks and Limitations

The Necessity of Configuration Control

While PCS is superior for this material, it is not a "plug and play" solution. The standard PCS setup allows current to pass through the die and sample; failing to implement the alumina insulation barrier will ruin an Ag2S1-xTex sample.

Sensitivity to Parameters

Because the heating rate is so fast, the process window is narrow. A deviation in pressure (50 MPa) or temperature (573 K) can lead to either incomplete densification or the very phase transformation you are trying to avoid. Precision in process control is mandatory.

Making the Right Choice for Your Goal

To maximize the quality of your Ag2S1-xTex samples, align your processing strategy with these priorities:

- If your primary focus is Phase Purity: Utilize the rapid heating capability of PCS to keep dwell times under 15 minutes, ensuring metastable amorphous phases are retained.

- If your primary focus is Compositional Uniformity: You must isolate the sample with alumina powder to prevent the electric field from driving non-uniform silver ion migration.

Success with this material requires treating time as a critical variable and electrical isolation as a mandatory constraint.

Summary Table:

| Feature | PCS Advantage for Ag2S1-xTex | Key Outcome |

|---|---|---|

| Heating Rate | Extremely rapid heating cycles | Minimal grain growth and phase preservation |

| Sintering Time | Short dwell times (e.g., 15 mins) | Retention of critical amorphous phases |

| Electrical Control | Use of alumina insulating barriers | Prevents silver ion drift and chemical segregation |

| Pressure Application | Uniaxial 50 MPa pressure | High densification at lower temperatures |

Unlock High-Performance Material Densification with KINTEK

Precision is paramount when processing sensitive materials like Ag2S1-xTex. Backed by expert R&D and manufacturing, KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside advanced high-temp lab furnaces. Whether you need to maintain metastable phases or prevent ion migration, our equipment is fully customizable to meet your unique research and production needs.

Ready to elevate your material properties? Contact us today to consult with our technical specialists and find the perfect sintering solution for your lab.

Visual Guide

References

- Kosuke Sato, Tsunehiro Takeuchi. Composition, time, temperature, and annealing-process dependences of crystalline and amorphous phases in ductile semiconductors Ag2S1−<i>x</i>Te<i>x</i> with <i>x</i> = 0.3–0.6. DOI: 10.1063/5.0180950

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is high-precision temperature control critical in SiC/Al sintering? Prevent Brittle Phases and Enhance Strength

- What is the purpose of in-situ reaction/hot pressing for (Ti0.95Nb0.05)3SiC2 targets? Achieve High Density Coatings

- What role does hot pressing play in materials science? Achieve High-Density, Complex Parts Efficiently

- What is hot press sintering and how is it used with metal and ceramic powders? Achieve Superior Density and Performance

- What is the principle of hot pressing in manufacturing? Achieve High-Density Components with Precision

- What physical conditions are provided by the heating plate and high-voltage DC power supply? Mastery of Anodic Bonding

- How are vacuum presses utilized in the aerospace and automotive industries? Enhance Performance with Lightweight Composites

- How is Vacuum Hot Press equipment used in R&D? Innovate with High-Purity Materials