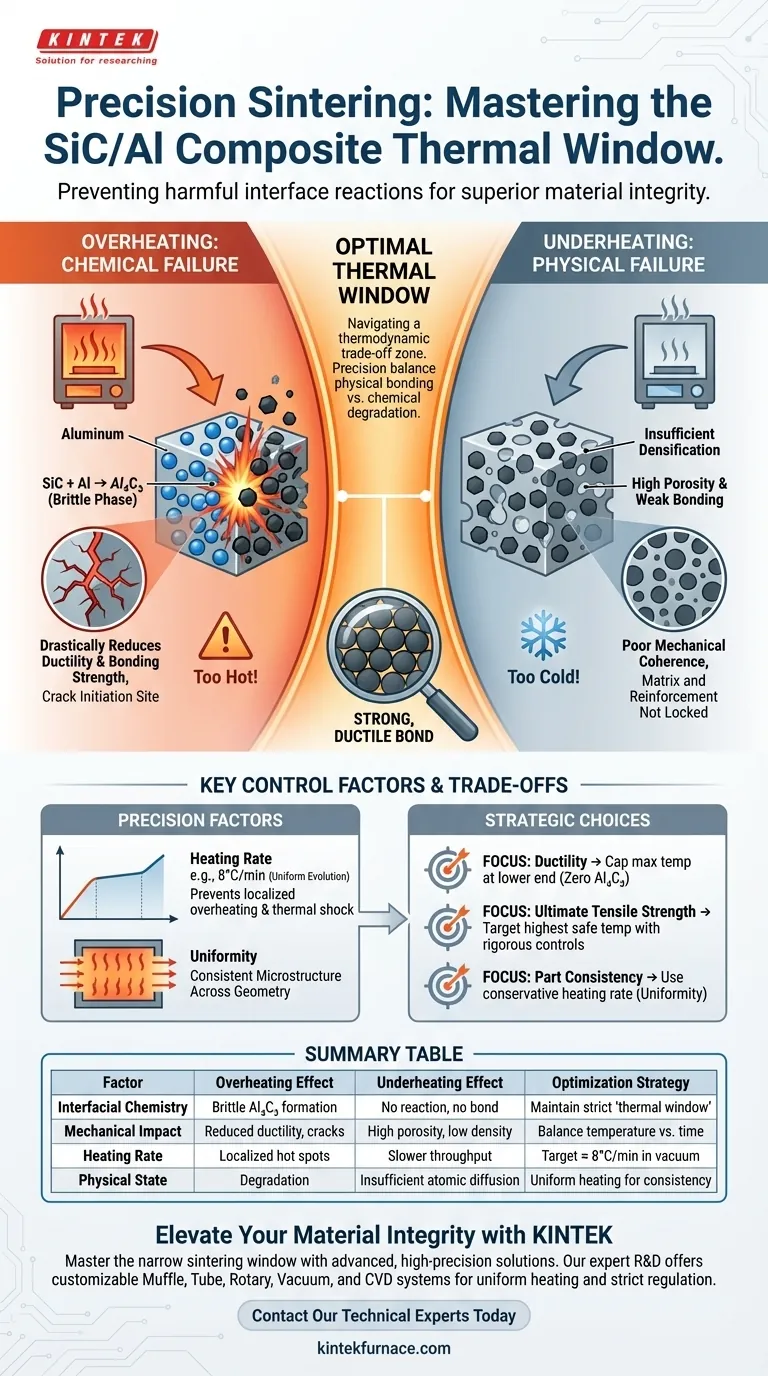

High-precision temperature control is the critical factor in preventing the formation of brittle phases while ensuring structural integrity during SiC/Al composite sintering.

If the temperature deviates even slightly above the optimal range, it triggers severe chemical reactions between the silicon carbide (SiC) and aluminum (Al), creating Aluminum Carbide ($Al_4C_3$). This brittle phase drastically reduces the material's ductility and bonding strength. Conversely, temperatures that are too low fail to provide the energy needed for proper densification, resulting in a weak, porous composite.

The Core Insight Sintering SiC/Al composites requires navigating a narrow "thermal window." Precision is not merely about reaching a target temperature; it is about balancing the thermodynamic requirements for physical bonding against the chemical risk of degrading the material interface.

The Chemistry of Failure: Why Overheating Matters

The Formation of Brittle Phases

When sintering temperatures exceed the specific thermal window, the chemical stability of the SiC/Al interface breaks down.

The excess heat acts as a catalyst for a harmful reaction, causing the aluminum matrix to consume the silicon carbide reinforcement. This generates $Al_4C_3$ (Aluminum Carbide), a highly brittle compound that forms at the interface.

Impact on Mechanical Properties

The presence of $Al_4C_3$ is detrimental to the composite's performance.

Instead of a strong, ductile bond between the metal and the ceramic, this brittle layer acts as a crack initiation site. It significantly degrades the ductility of the final part, making it prone to catastrophic failure under stress rather than deforming plastically.

The Physical Consequence: The Risk of Underheating

Insufficient Densification

While overheating causes chemical degradation, underheating causes physical structural weakness.

If the temperature is too low, the material does not achieve the necessary energy state for atoms to diffuse and bond effectively. This leads to insufficient densification, leaving the composite with internal porosity and poor mechanical coherence.

Compromised Bonding Strength

Without adequate heat, the matrix cannot flow or bond effectively around the reinforcement.

This results in weak interfacial bonding strength. Even if no harmful chemical reactions occur, the composite will fail because the matrix and reinforcement are not mechanically locked together.

The Role of Heating Rates and Uniformity

Preventing Local Overheating

Precision control extends beyond the final hold temperature; it also applies to the heating rate.

Rapid temperature increases can cause "overshoot" or local hot spots within the powder compact. Even if the furnace sensor reads a safe temperature, specific areas of the part may briefly exceed the threshold, triggering the formation of brittle phases in localized pockets.

Ensuring Microstructural Evolution

A controlled heating rate (e.g., $8^\circ C/min$ in vacuum conditions) allows the microstructure to evolve uniformly.

This prevents thermal shock and ensures that the entire cross-section of the composite experiences the same thermal history. Uniform heating minimizes internal defects and ensures the material properties are consistent throughout the part.

Understanding the Trade-offs

The Thermodynamic Window

The primary challenge in sintering SiC/Al is that the temperature required for densification is dangerously close to the temperature that triggers chemical degradation.

You are effectively operating in a thermodynamic trade-off zone. Prioritizing speed or higher density by raising the temperature immediately risks the creation of brittle $Al_4C_3$. Prioritizing safety by lowering the temperature risks leaving the material porous and weak.

Process Stability vs. Efficiency

High-precision control often requires slower ramp rates and sophisticated monitoring, which can reduce manufacturing throughput.

However, attempting to speed up the process reduces the margin for error. A faster process increases the likelihood of thermal gradients, where the core of the part might be under-sintered while the surface is chemically degraded.

Making the Right Choice for Your Goal

To optimize the performance of SiC/Al composites, you must tune your thermal profile to your specific performance requirements.

- If your primary focus is Ductility: Cap your maximum temperature strictly to the lower end of the sintering window to guarantee zero formation of the brittle $Al_4C_3$ phase.

- If your primary focus is Ultimate Tensile Strength: Target the highest safe temperature within the window to maximize densification, but employ rigorous heating rate controls to prevent local overheating.

- If your primary focus is Part Consistency: Use a conservative heating rate (e.g., $8^\circ C/min$) to ensure the microstructure evolves uniformly across the entire geometry.

Ultimately, the success of SiC/Al sintering depends not on how much heat you apply, but on how precisely you limit that heat to the zone of safe interaction.

Summary Table:

| Factor | Effect of Overheating | Effect of Underheating | Optimization Strategy |

|---|---|---|---|

| Interfacial Chemistry | Formation of brittle $Al_4C_3$ | No reaction; lack of bonding | Maintain strict 'thermal window' |

| Mechanical Impact | Reduced ductility & crack risk | High porosity & low density | Balance temperature vs. time |

| Heating Rate | Localized hot spots/overshoot | Slower throughput | Target $\approx 8^\circ C/min$ in vacuum |

| Physical State | Material degradation | Insufficient atomic diffusion | Uniform heating for consistency |

Elevate Your Material Integrity with KINTEK

Don't let imprecise thermal profiles compromise your SiC/Al composites. KINTEK provides the advanced high-temperature solutions you need to master the narrow sintering window.

Backed by expert R&D and manufacturing, we offer high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory and production requirements. Whether you are aiming for maximum ductility or ultimate tensile strength, our systems ensure the uniform heating and strict temperature regulation essential for preventing brittle phase formation.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect furnace for your specialized needs.

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is hot pressing sintering and how does vacuum hot pressing sintering improve the process? Achieve Superior Material Density and Purity

- What is the primary purpose of using a high-precision laboratory uniaxial hydraulic press to compact powders?

- How does a Hot Pressing (HP) furnace contribute to the densification of Titanium Diboride ceramics? Expert Solutions

- What industrial applications utilize vacuum hot press furnaces? Essential for Aerospace, Medical, and Electronics

- What is a hot press machine used for? From custom apparel to aerospace components

- Why is a high vacuum environment crucial when preparing copper-carbon nanotube composites in a vacuum hot press furnace? Achieve Superior Composite Integrity

- How does a Vacuum Hot Pressing (VHP) furnace prepare high-performance P-type Mg3Sb2 thermoelectric materials?

- What is the maximum working temperature of a vacuum hot press furnace? Achieve Precise High-Temp Processing