The integrity of copper-carbon nanotube (Cu-CNT) composites relies fundamentally on the purity of the sintering environment. A high vacuum is critical because it simultaneously prevents the oxidation of the copper matrix and the nanotubes while actively extracting adsorbed gases from the powder surfaces. Without this controlled atmosphere, the material cannot achieve the atomic-level contact required for high electrical conductivity and superior mechanical strength.

The Core Reality Creating a viable Cu-CNT composite is less about heating the material and more about managing the interface between the metal and the reinforcement. A high vacuum environment is the primary mechanism that removes oxide barriers and gas pockets, facilitating the direct atomic diffusion necessary for a dense, high-performance composite.

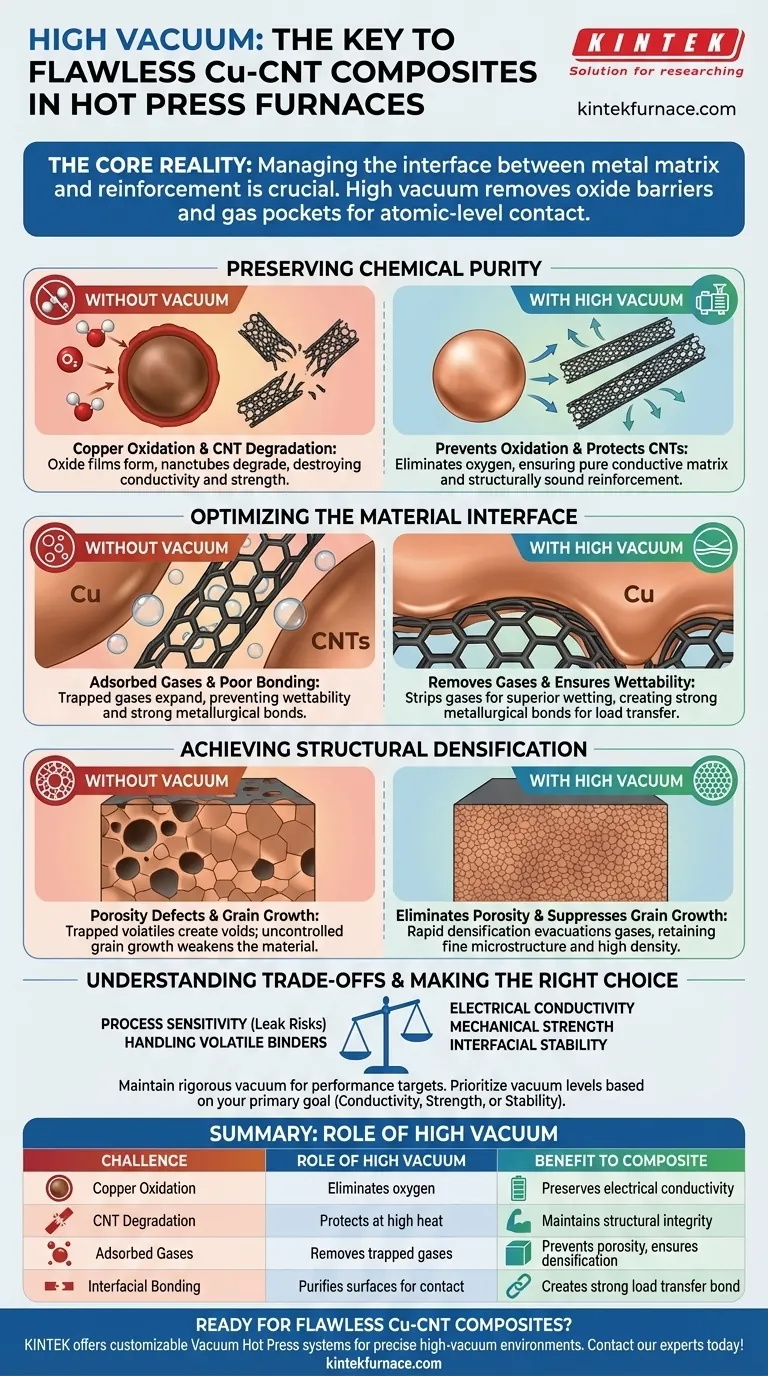

Preserving Chemical Purity at High Temperatures

Preventing Copper Matrix Oxidation

At the elevated temperatures required for sintering, copper is highly reactive with oxygen. Without a vacuum, oxide films form rapidly on the surface of the copper particles.

These oxide layers act as electrical insulators and mechanical weak points. A high vacuum environment (often around $10^{-5}$ mbar) eliminates oxygen, ensuring the copper matrix remains pure and conductive.

Protecting the Carbon Nanotubes

Carbon nanotubes (CNTs) act as the reinforcement phase, but they are also susceptible to degradation in the presence of oxygen at high heat.

The vacuum environment protects the structural integrity of the CNTs. This preservation is vital, as any damage to the nanotube structure compromises the mechanical reinforcement they provide to the composite.

Optimizing the Material Interface

Removing Adsorbed Gases

Milled powders, particularly those used in composite preparation, possess high specific surface areas that trap significant amounts of adsorbed gases.

If these gases are not evacuated, they expand during heating. A high vacuum effectively strips these gases from the particle surfaces before the sintering phase begins.

Ensuring Wettability and Bonding

Strong interfacial bonding relies on "wettability"—the ability of the metal to flow over and adhere to the reinforcement.

By purifying the powder surface and removing contaminants, the vacuum improves the wettability between the copper and the CNTs. This leads to a strong metallurgical bond, which is essential for effective load transfer within the composite.

Achieving Structural Densification

Eliminating Porosity Defects

Porosity is the enemy of mechanical strength. Trapped gases and volatiles that are not removed during the initial stages of heating create voids (pores) in the final product.

The vacuum environment evacuates gases from the interstitial spaces between powder particles. This allows the material to densify rapidly and completely while in a thermoplastic state.

Suppressing Grain Growth

While densification is desired, uncontrolled grain growth can weaken the material.

Vacuum hot pressing facilitates rapid densification, which effectively suppresses excessive grain growth. This balance results in a bulk material that retains a fine microstructure and high density.

Understanding the Trade-offs

Process Sensitivity and Leak Risks

While a high vacuum is indispensable, it introduces significant process sensitivity. The equipment requires rigorous maintenance of seals and pumps.

Even a minor leak or a failure to reach the specific vacuum threshold can result in partial oxidation. This is often more detrimental than total failure, as it creates invisible defects inside the composite that lead to unpredictable performance.

Handling Volatile Binders

In some preparation methods involving binders or waxes, the vacuum assists in extracting these volatiles.

However, this requires careful ramp-up rates. If the vacuum pulls too hard too quickly on volatile binders, it can disrupt the powder arrangement before sintering occurs.

Making the Right Choice for Your Goal

When configuring your vacuum hot press parameters, consider your specific performance targets:

- If your primary focus is Electrical Conductivity: Prioritize the highest possible vacuum levels to ensure the complete removal of oxide films, which act as barriers to electron flow.

- If your primary focus is Mechanical Strength: Focus on the evacuation of interstitial gases to minimize porosity, ensuring a fully dense structure that can withstand physical loads.

- If your primary focus is Interfacial Stability: Ensure the vacuum is maintained during the cooling phase to prevent re-oxidation of the surface while the material is still chemically active.

The vacuum is not merely a protective measure; it is an active processing tool that dictates the final quality of the interface between your matrix and reinforcement.

Summary Table:

| Challenge | Role of High Vacuum | Benefit to Composite |

|---|---|---|

| Copper Oxidation | Eliminates oxygen from the chamber | Preserves electrical conductivity of the matrix |

| CNT Degradation | Protects nanotubes from oxygen at high heat | Maintains structural integrity for mechanical reinforcement |

| Adsorbed Gases | Removes gases trapped on powder surfaces | Prevents porosity and ensures complete densification |

| Interfacial Bonding | Purifies surfaces for better metal-to-CNT contact | Creates a strong bond for effective load transfer |

Ready to achieve flawless Cu-CNT composites? The right furnace is critical. Backed by expert R&D and manufacturing, KINTEK offers customizable Vacuum Hot Press systems, including Muffle, Tube, Rotary, and CVD furnaces, designed to deliver the precise high-vacuum environment your research demands.

Contact our experts today to discuss how we can tailor a solution for your unique composite preparation needs.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is it necessary to maintain a high vacuum environment during the SPS of SiC? Key to High-Density Ceramics

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- How does precise temperature control in a vacuum hot press furnace affect Al-Si/graphite? Optimize Interface Bonding

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What is the impact of grain structure on material properties in hot pressing vs. cold compacting and sintering? Optimize Your Powder Metallurgy Process

- How does a vacuum press work? Harness Atmospheric Pressure for Perfect Clamping

- Why are high-purity graphite sleeves used in Multi-anvil Presses? Unlock 2300°C Precision and Reducing Environments

- Why is multi-stage pressure regulation required in a vacuum hot press furnace? Optimize Ti-Al3Ti Composite Sintering