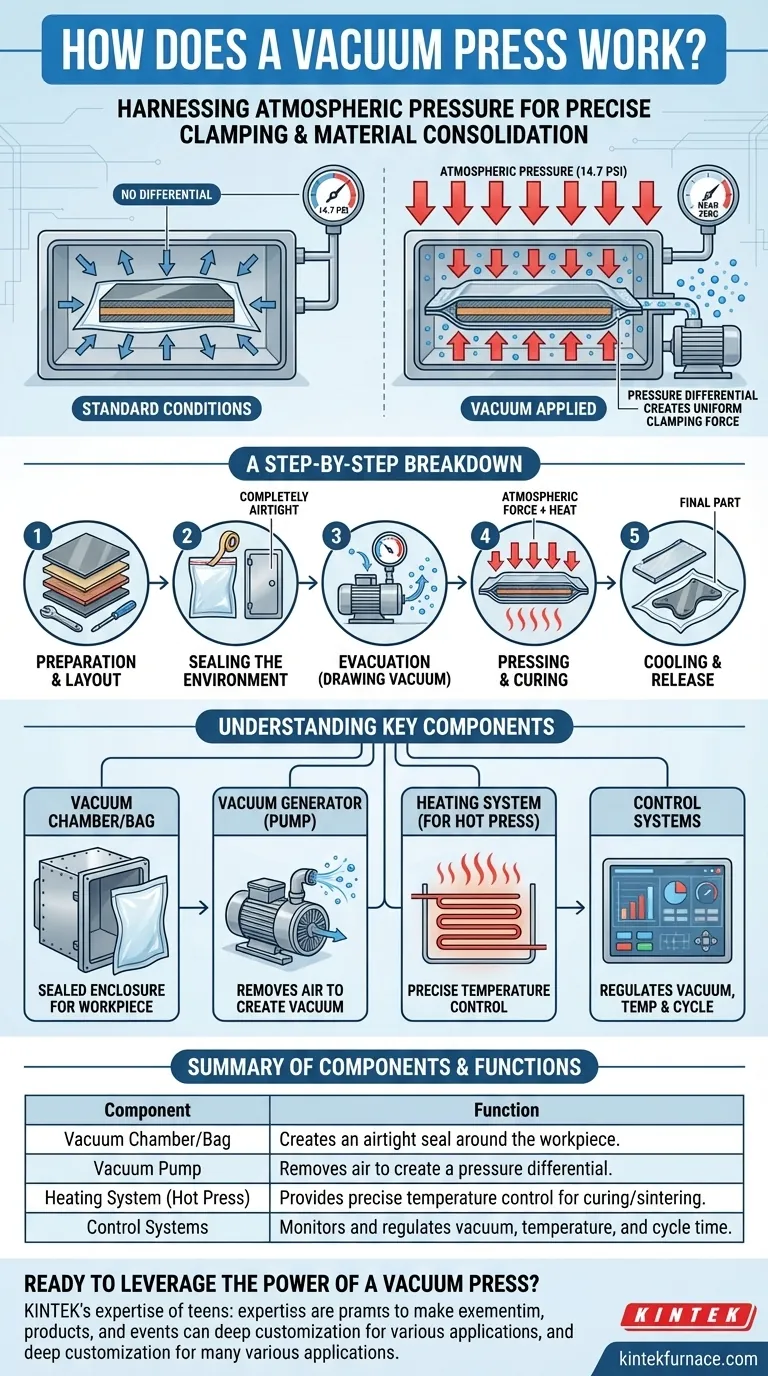

At its core, a vacuum press works by removing air from a sealed bag or chamber to let the immense weight of the atmosphere provide clamping force. Instead of using mechanical clamps, it uses a pressure differential, where the higher atmospheric pressure outside pushes down uniformly on the object inside the vacuum.

A vacuum press is not simply a clamp; it is a controlled environment. By removing air, it simultaneously applies perfectly uniform pressure and eliminates airborne contaminants, enabling the creation of advanced materials that are impossible to produce with conventional methods.

The Fundamental Principle: Harnessing Atmospheric Pressure

A vacuum press operates on a simple but powerful physics principle. The entire system is designed to leverage the natural weight of the Earth's atmosphere.

Creating a Pressure Differential

First, the materials to be pressed are placed inside an airtight container, which can be a flexible bag or a rigid chamber. A vacuum pump is then used to evacuate the air from this sealed environment.

As air is removed, the pressure inside the bag drops close to zero. The pressure outside the bag, however, remains the same—the standard atmospheric pressure.

The Power of the Atmosphere

At sea level, the atmosphere exerts a pressure of approximately 14.7 pounds per square inch (PSI), or about 1 ton per square foot.

When a vacuum is drawn inside the bag, this external atmospheric pressure pushes down on every square inch of the bag's surface, creating a powerful and perfectly distributed clamping force. This is what presses laminates onto curved forms or consolidates composite layers together.

A Step-by-Step Breakdown of the Process

The operation of a vacuum press, whether for woodworking or advanced materials science, follows five essential steps.

Step 1: Preparation and Layout

The workpiece, adhesives, and any molds or forms are carefully arranged inside the vacuum bag or chamber. For composites, this involves laying up layers of fabric (like carbon fiber) and resin.

Step 2: Sealing the Environment

The bag or chamber must be made completely airtight. For bags, this usually involves sealing the open end with a special tacky tape and closure system. For rigid chambers, it involves closing and sealing a heavy-duty door.

Step 3: Evacuation (Drawing the Vacuum)

The vacuum pump is switched on. It removes air and other gases (like fumes from resin) from the sealed environment. A gauge is used to monitor the level of vacuum to ensure it reaches the target for the specific process.

Step 4: Pressing and Curing

Once the vacuum is achieved, atmospheric pressure takes over, applying force to the workpiece. At this stage, some processes require heat, which is introduced by a heating system. This is known as hot pressing and is used to cure resins, sinter powders, or diffusion-bond metals.

Step 5: Cooling and Release

After the curing or bonding cycle is complete, the part is often allowed to cool under vacuum to maintain its shape and prevent warping. Finally, the vacuum is released, the pressure equalizes, and the finished part can be removed.

Understanding the Key Components

Every vacuum press is built around a few core components that work together to create the desired effect.

The Vacuum Chamber or Bag

This is the sealed enclosure that holds the workpiece. It can be a flexible vinyl or silicone bag for large or irregularly shaped objects, or a robust metal chamber for high-temperature industrial processes.

The Vacuum Generator (Pump)

This is the heart of the system. The pump is responsible for removing the air from the chamber or bag to create the vacuum. The strength and type of pump determine how quickly and how low the pressure can go.

The Heating System (For Hot Presses)

In a vacuum hot press, a heating system—often using electrical resistance elements—is integrated into the chamber. This allows for precise temperature control during the pressing cycle, which is critical for processing advanced materials.

The Control Systems

Modern presses use sophisticated control systems to regulate and monitor vacuum levels, temperature, and cycle times. This precision is essential for repeatability and for meeting the strict specifications required in aerospace and industrial manufacturing.

Making the Right Choice for Your Goal

Understanding the core function of a vacuum press allows you to select the right approach for a specific task.

- If your primary focus is woodworking or laminating panels: A standard vacuum bag press is ideal, as it provides perfectly even clamping pressure over complex curves and large surfaces without the risk of marking the wood.

- If your primary focus is creating advanced composites (like carbon fiber): A vacuum is non-negotiable for removing air voids between layers and ensuring maximum strength-to-weight ratio in the final part.

- If your primary focus is materials science and research: A vacuum hot press is necessary for sintering powders, creating dense ceramics, and diffusion bonding metals in a contaminant-free environment.

By understanding this principle, you can leverage atmospheric pressure to achieve results far beyond the reach of traditional clamping methods.

Summary Table:

| Component | Function |

|---|---|

| Vacuum Chamber/Bag | Creates an airtight seal around the workpiece. |

| Vacuum Pump | Removes air to create a pressure differential. |

| Heating System (Hot Press) | Provides precise temperature control for curing/sintering. |

| Control Systems | Monitors and regulates vacuum, temperature, and cycle time. |

Ready to leverage the power of a vacuum press for your application?

Whether you are involved in woodworking, composite manufacturing, or advanced materials research, KINTEK's expertise can help you achieve superior results. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace and press solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Contact our experts today via our Contact Form to discuss how a customized vacuum press solution can enhance your process.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing