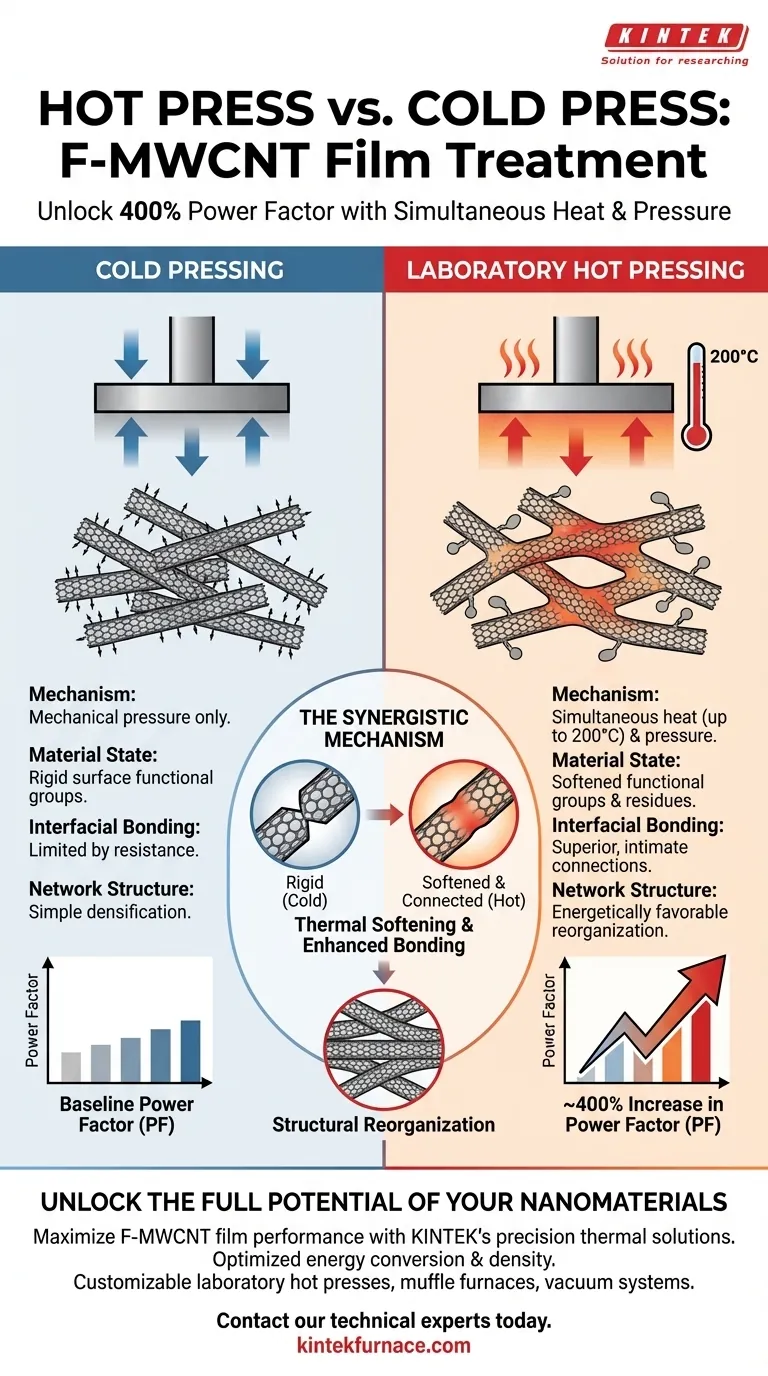

A laboratory hot press offers a decisive advantage over cold pressing by applying simultaneous thermal energy and mechanical pressure to the sample. While cold pressing relies solely on force to densify the material, adding a controlled thermal environment fundamentally alters how the functionalized multi-walled carbon nanotube (F-MWCNT) network organizes itself.

Core Takeaway: By integrating heat (up to 200°C) with mechanical pressure, you soften surface functional groups to create significantly tighter nanotube connections. This synergistic effect promotes structural reorganization and can increase the Power Factor (PF) of the films by approximately 400% compared to cold-pressed samples.

The Synergistic Mechanism of Heat and Pressure

Thermal Softening of Functional Groups

The primary limitation of cold pressing is that it works against the material's natural rigidity. In a hot press, the heat serves to soften the functional groups and residues located on the nanotube surfaces.

Enhancing Interfacial Bonding

When these surface groups soften, they become more malleable. This allows the mechanical pressure to force the nanotubes into tighter, more intimate connections than would be possible at room temperature. The result is superior interfacial bonding between the individual nanotubes.

Quantifiable Performance Gains

Structural Reorganization

The combination of heat and pressure does more than just compact the film; it drives a structural reorganization of the carbon nanotube network. The thermal energy allows the network to settle into a more energetically favorable, efficient configuration.

Significant Increase in Power Factor

The structural benefits translate directly into measurable performance metrics. Data indicates that this synchronized thermal and mechanical action boosts the Power Factor (PF) of the films by approximately 400% compared to samples that were only cold-pressed.

Understanding the Operational Parameters

Controlled Thermal Environment

The advantages of this method rely on precise temperature regulation. The process utilizes a controlled environment capable of reaching up to 200°C.

The Necessity of Synchronization

It is not enough to simply heat the sample before or after pressing. The simultaneity of the thermal and mechanical forces is the key factor that locks the structural reorganization into place, ensuring the performance gains are permanent.

Making the Right Choice for Your Goal

To maximize the efficiency of your F-MWCNT films, consider the following recommendations based on your performance targets:

- If your primary focus is maximizing energy conversion: Adopt a hot press workflow to capitalize on the potential 400% increase in Power Factor.

- If your primary focus is optimizing network density: Utilize the heating capabilities to soften residues, ensuring the tightest possible interfacial bonding between nanotubes.

Integrating simultaneous heat and pressure is the most effective method for unlocking the full electrical potential of functionalized nanotube networks.

Summary Table:

| Feature | Cold Pressing | Laboratory Hot Pressing |

|---|---|---|

| Mechanism | Mechanical pressure only | Simultaneous heat (up to 200°C) & pressure |

| Material State | Rigid surface functional groups | Softened functional groups & residues |

| Interfacial Bonding | Limited by material resistance | Superior, intimate nanotube connections |

| Network Structure | Simple densification | Energetically favorable reorganization |

| Power Factor (PF) | Baseline performance | ~400% Increase compared to cold press |

| Primary Outcome | Basic compaction | Optimized energy conversion & density |

Unlock the Full Potential of Your Nanomaterials

Maximize the performance of your F-MWCNT films with KINTEK’s precision thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of laboratory hot presses, muffle furnaces, and vacuum systems, all customizable to meet your specific research parameters. Whether you need to optimize interfacial bonding or achieve a 400% boost in Power Factor, our systems provide the synchronized control necessary for breakthrough results.

Ready to elevate your material science? Contact our technical experts today to find the perfect high-temp solution for your lab.

Visual Guide

References

- Nimra Naeem, Muhammad Farooq. Facile development of carbon nanotube (CNT)-based flexible thermoelectric materials for energy-harvesting applications. DOI: 10.1039/d4ra02914c

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role do vacuum hot press furnaces play in research and development laboratories? Unlock Next-Gen Material Innovations

- What are the advantages of using hot deep drawing equipment for TC4 alloy? Achieve Smooth, Wrinkle-Free Parts

- Why is a Vacuum Hot Pressing Sintering Furnace Essential for 6061-20IQC? Unlock High-Performance Composites

- What is the difference between hot pressing and sintering? Choose the Right Process for Your Materials

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- Why is multi-stage pressure regulation required in a vacuum hot press furnace? Optimize Ti-Al3Ti Composite Sintering

- How does a Vacuum Hot Pressing (VHP) furnace prepare high-performance P-type Mg3Sb2 thermoelectric materials?

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity