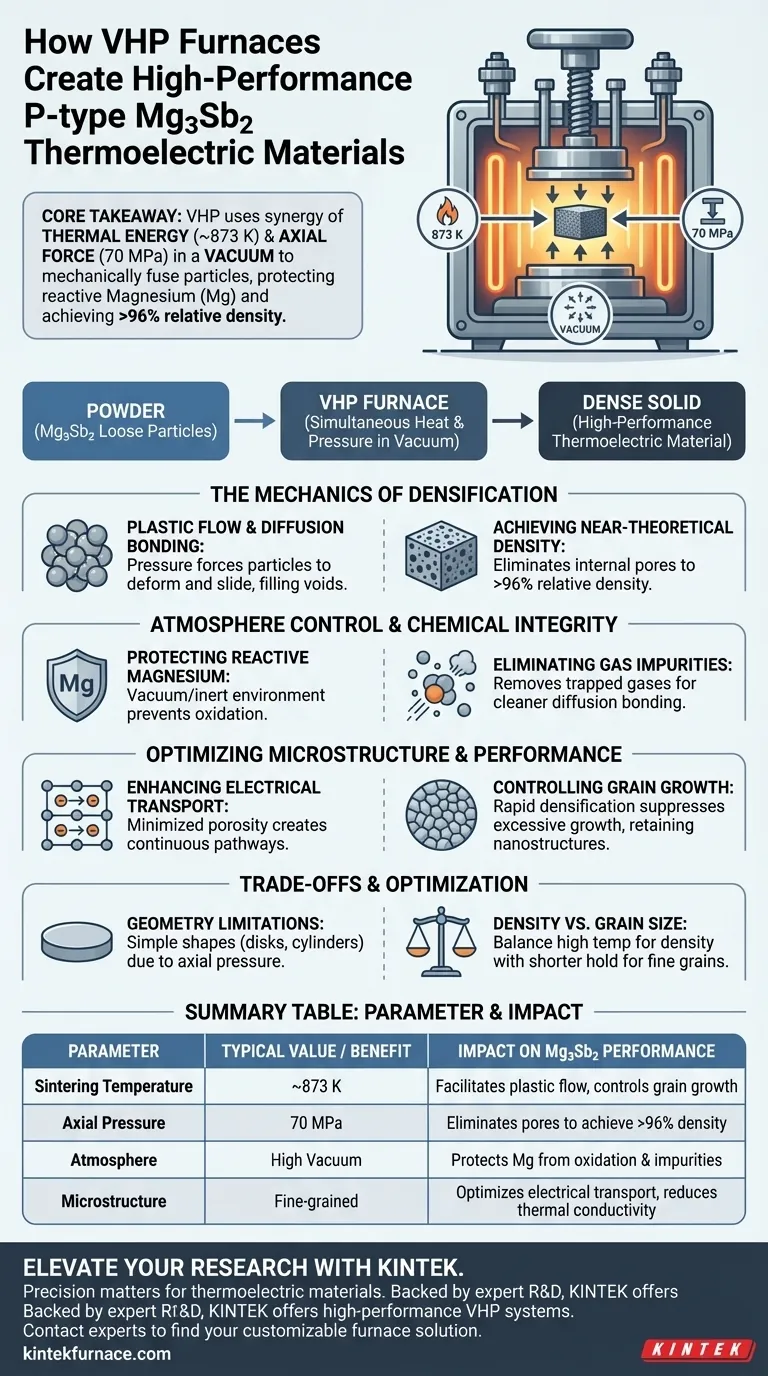

A Vacuum Hot Pressing (VHP) furnace is the critical processing tool used to transform loose powder into a dense, high-performance thermoelectric solid. By simultaneously applying high mechanical pressure (typically 70 MPa) and high temperature (around 873 K) within a vacuum, the furnace forces powder particles to bond via plastic flow, effectively eliminating pores to achieve a relative density exceeding 96%.

The Core Takeaway The VHP furnace does not merely heat the material; it utilizes the synergy of thermal energy and axial force to mechanically fuse particles while protecting the highly reactive magnesium from oxidation. This results in a mechanically robust material with the high density required for optimal electrical transport properties.

The Mechanics of Densification

Simultaneous Heat and Pressure

The defining feature of VHP is the concurrent application of thermal and mechanical energy. In the preparation of P-type Mg3Sb2, the furnace applies a temperature of approximately 873 K alongside an axial pressure of 70 MPa.

Plastic Flow and Diffusion Bonding

This combination triggers specific physical mechanisms: plastic flow and diffusion bonding. The pressure forces the powder particles to deform and slide against one another, filling voids that heat alone might leave behind.

Achieving Near-Theoretical Density

The result of this process is the elimination of internal pores. The material achieves a relative density of over 96%, which is significantly higher than what is typically achievable through pressureless sintering.

Chemical Integrity and Atmosphere Control

Protecting Reactive Magnesium

Magnesium (Mg) is highly reactive and prone to oxidation. The VHP furnace operates in a vacuum or inert environment, which is essential for preventing the formation of oxides that would degrade thermoelectric performance.

Eliminating Gas Impurities

The vacuum environment actively removes gas impurities trapped between particles. This ensures that the diffusion bonding occurs between clean surfaces, leading to a more homogeneous and conductive alloy.

Optimizing Microstructure for Performance

Enhancing Electrical Transport

High density is directly linked to electrical performance. By minimizing porosity, the VHP process creates a continuous pathway for charge carriers, thereby optimizing the material's electrical conductivity and overall thermoelectric efficiency.

Controlling Grain Growth

VHP allows for rapid densification at relatively lower temperatures compared to other methods. This speed effectively suppresses excessive grain growth, allowing the material to retain beneficial nanostructural characteristics that can lower thermal conductivity.

Understanding the Trade-offs

Geometry Limitations

Because the pressure is applied axially (from top and bottom), VHP is generally limited to producing simple shapes, such as disks or cylinders. Complex geometries often require additional machining after the hot pressing process.

The Density vs. Grain Size Balance

While high temperature promotes density, it also encourages grains to grow larger, which can negatively impact thermoelectric properties. Precise control of the heating program is required to maximize density without destroying the fine-grained microstructure.

Making the Right Choice for Your Goal

To maximize the potential of your Mg3Sb2 material, tailor your VHP parameters to your specific performance targets:

- If your primary focus is mechanical strength and electrical conductivity: Prioritize maximum pressure (e.g., 70 MPa) and sufficient hold times to ensure relative density exceeds 96%.

- If your primary focus is reducing thermal conductivity: Optimize for shorter holding times and the lowest effective sintering temperature to suppress grain growth and retain nanostructures.

The VHP furnace is not just a heating element; it is a precision tool for engineering the density and purity required for superior thermoelectric conversion.

Summary Table:

| Parameter | Typical Value / Benefit | Impact on P-type Mg3Sb2 Performance |

|---|---|---|

| Sintering Temperature | ~873 K | Facilitates plastic flow while controlling grain growth |

| Axial Pressure | 70 MPa | Eliminates pores to achieve >96% relative density |

| Atmosphere | High Vacuum | Protects reactive Magnesium from oxidation and impurities |

| Microstructure | Fine-grained | Optimizes electrical transport and reduces thermal conductivity |

Elevate Your Materials Research with KINTEK

Precision matters when engineering the next generation of thermoelectric materials. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Pressing systems, Muffle, Tube, Rotary, and CVD furnaces specifically designed to meet the rigorous demands of advanced lab environments.

Whether you are processing reactive alloys like Mg3Sb2 or require customizable high-temperature solutions for unique applications, our systems provide the precise control over temperature and pressure you need to achieve near-theoretical density and superior purity.

Ready to optimize your material performance? Contact KINTEK experts today to find the perfect customizable furnace solution for your laboratory.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why are graphite molds critical for Cu/rGO vacuum hot pressing? Enhance Precision and Densification

- What applications does Vacuum Hot Press technology have in the electronics and semiconductor industry? Unlock High-Performance Component Manufacturing

- What are the primary advantages of FAST/SPS in Ti-6Al-4V recycling? Transform Efficiency with Solid-State Sintering

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys

- What is the significance of the rapid heating capability of a hot press furnace? Unlock Nanoscale Sintering Precision

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the advantages of industrial SPS vs traditional sintering for SiC? Superior Density and Fine-Grain Structure

- What are the steps in the hot press sintering process? Achieve Superior Material Density and Performance