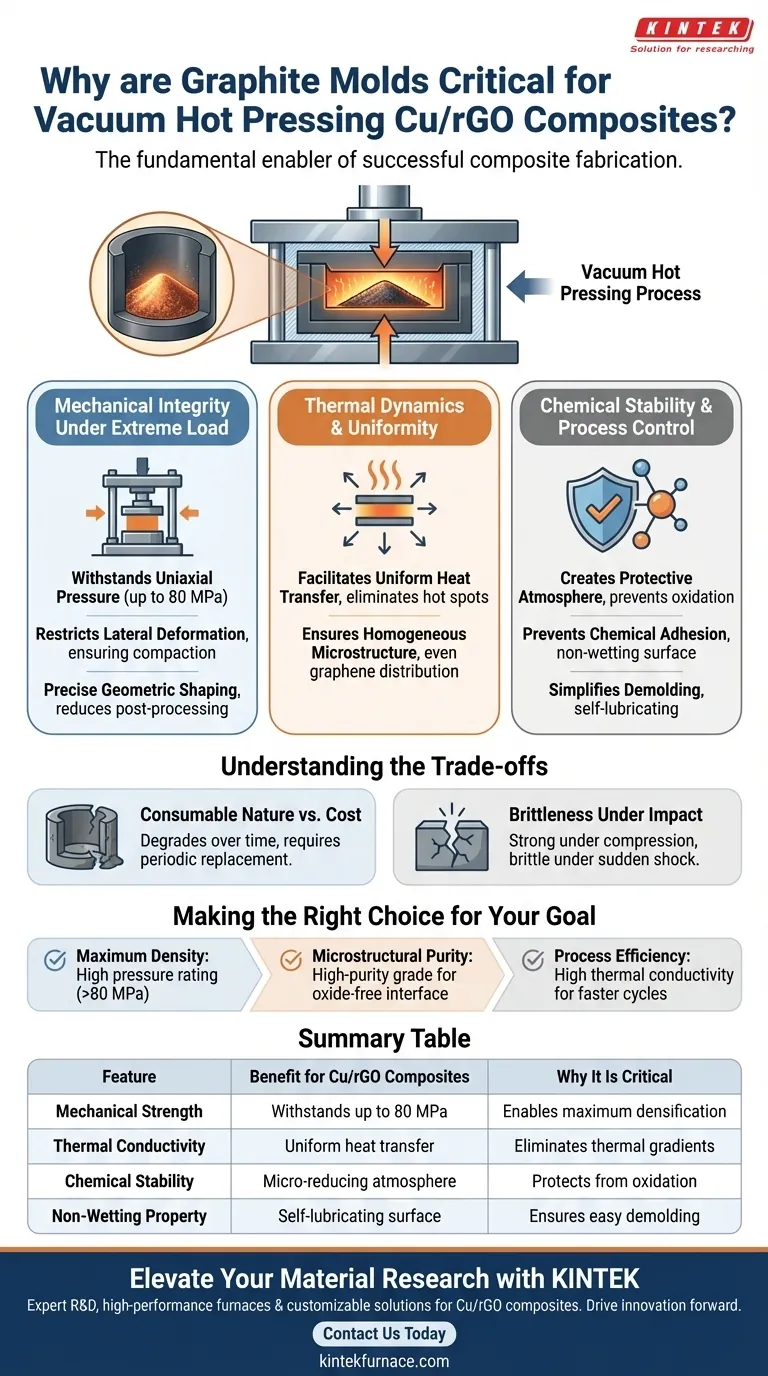

Graphite molds are the fundamental enabler of successful vacuum hot pressing for Copper/reduced Graphene Oxide (Cu/rGO) composites. They are considered critical consumables because they combine exceptional high-temperature strength with superior thermal conductivity. These properties allow the molds to withstand significant uniaxial pressures (up to 80 MPa) without deforming, ensuring the composite material is precisely shaped and achieves a uniform microstructure during the sintering process.

The core value of graphite molds lies in their ability to maintain structural rigidity while ensuring thermal equilibrium. They transmit the massive mechanical force required for densification while simultaneously creating a stable chemical environment that protects the copper matrix from oxidation.

Mechanical Integrity Under Extreme Load

Withstanding Uniaxial Pressure

The primary function of the graphite mold is to act as a load-bearing container.

In vacuum hot pressing, the Cu/rGO powder mixture must be compressed to achieve high density. Graphite molds can withstand significant uniaxial pressures, such as 80 MPa, without succumbing to fracture or creep. This allows for maximum densification of the composite powders.

Restricting Lateral Deformation

While the press applies vertical force, the mold must contain the powder horizontally.

High-strength graphite resists lateral expansion, effectively confining the powder mixture. This ensures that the applied pressure is directed entirely toward consolidating the material rather than deforming the container.

Precise Geometric Shaping

Because graphite retains its dimensions at high temperatures, it acts as a precise forming tool.

It defines the final geometry of the sample, ensuring that the sintered Cu/rGO composite emerges with accurate dimensions and flat surfaces. This reduces the need for extensive post-processing or machining.

Thermal Dynamics and Uniformity

Facilitating Uniform Heat Transfer

Graphite possesses excellent thermal conductivity, which is vital for the sintering process.

It transfers heat quickly and evenly from the heating elements to the internal composite powder. This eliminates "hot spots" or "cold zones" within the mold, which could otherwise lead to uneven sintering or cracking.

Ensuring Homogeneous Microstructure

Thermal uniformity directly translates to structural quality.

By ensuring the entire sample reaches the sintering temperature simultaneously, the graphite mold promotes a uniform microstructure. This is critical for Cu/rGO composites, as it ensures the graphene reinforcement is evenly distributed and bonded within the copper matrix.

Chemical Stability and Process Control

Creating a Protective Atmosphere

Graphite offers a unique chemical advantage when working with copper.

In a vacuum environment, the graphite mold can generate a micro-reducing atmosphere. This helps scavenge residual oxygen, further protecting the copper matrix from oxidation during the high-temperature cycle.

Preventing Chemical Adhesion

Graphite is chemically stable and generally inert regarding the copper matrix at sintering temperatures.

It resists severe chemical adhesion, meaning the molten or sintered metal does not bond to the mold walls. This compatibility is crucial for preserving the surface integrity of the composite.

Simplifying Demolding

The physical properties of graphite facilitate the manufacturing workflow.

Graphite is naturally self-lubricating and non-wetting to many metals. This makes the demolding operation significantly easier after sintering, reducing the risk of damaging the sample during extraction.

Understanding the Trade-offs

Consumable Nature vs. Cost

While mechanically robust, graphite molds are ultimately consumables.

They degrade over time due to repeated thermal cycling and mechanical stress. You must account for the periodic replacement of molds in your operational costs, as using a worn mold can compromise dimensional accuracy.

Brittleness Under Impact

Graphite is strong under compression but brittle under tension or impact.

Care must be taken during handling and loading. A sudden shock or uneven loading during the press setup can cause the mold to crack before the sintering process even begins.

Making the Right Choice for Your Goal

To maximize the quality of your Cu/rGO composites, you must match your mold selection to your specific processing parameters.

- If your primary focus is Maximum Density: Ensure your graphite grade is rated for pressures exceeding 80 MPa to prevent mold wall deflection during the compaction phase.

- If your primary focus is Microstructural Purity: Rely on high-purity graphite to enhance the micro-reducing effect, ensuring the copper interface remains oxide-free.

- If your primary focus is Process Efficiency: Prioritize graphite with high thermal conductivity ratings to shorten heating cycles and improve throughput.

The graphite mold is not just a container; it is an active participant in the thermal and mechanical history of your final material.

Summary Table:

| Feature | Benefit for Cu/rGO Composites | Why It Is Critical |

|---|---|---|

| Mechanical Strength | Withstands up to 80 MPa | Enables maximum densification without mold deformation. |

| Thermal Conductivity | Uniform heat transfer | Eliminates thermal gradients for a homogeneous microstructure. |

| Chemical Stability | Micro-reducing atmosphere | Protects the copper matrix from oxidation during sintering. |

| Non-Wetting Property | Self-lubricating surface | Ensures easy demolding and preserves sample surface integrity. |

Elevate Your Material Research with KINTEK

Precision in vacuum hot pressing starts with the right equipment and consumables. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside customizable lab high-temp furnaces tailored to your unique research needs.

Whether you are developing advanced Cu/rGO composites or exploring new alloy frontiers, our team provides the technical expertise to ensure your sintering process is efficient, uniform, and scalable. Contact us today to discuss your specific requirements and discover how our specialized furnace solutions can drive your innovation forward.

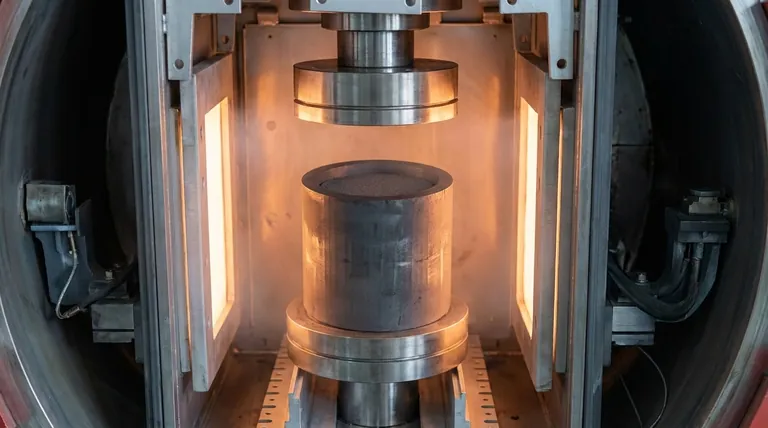

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is hot pressing and what does it involve? Unlock Superior Material Density and Strength

- What is hot pressing and how does it work? Achieve Superior Material Density and Strength

- What is the role of sacrificial inserts in the Spark Plasma Sintering (SPS) process? Master Complex Geometry Design

- What factors should be considered when choosing a vacuum press for metalworking? Optimize Your Investment for Precision and Efficiency

- What critical environmental conditions does a vacuum hot press furnace provide? Optimizing Copper-MoS2-Mo Composites

- Why are hot press furnaces essential in research and development? Unlock Advanced Material Innovations

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- How does a vacuum hot press furnace benefit sintering experiments? Achieve Superior Material Density and Purity