In research and development, a hot press furnace is essential because it is one of the few tools that can simultaneously apply high temperature, high mechanical pressure, and a controlled atmosphere. This unique combination allows scientists to create novel materials with superior density, explore new manufacturing techniques on a small scale, and study how materials behave under extreme conditions that mimic demanding industrial applications.

The core value of a hot press furnace in R&D is its ability to force powdered materials to bond and densify into a solid, near-perfect state without melting them. This process, known as sintering, is critical for fabricating advanced ceramics, composites, and alloys that cannot be made any other way.

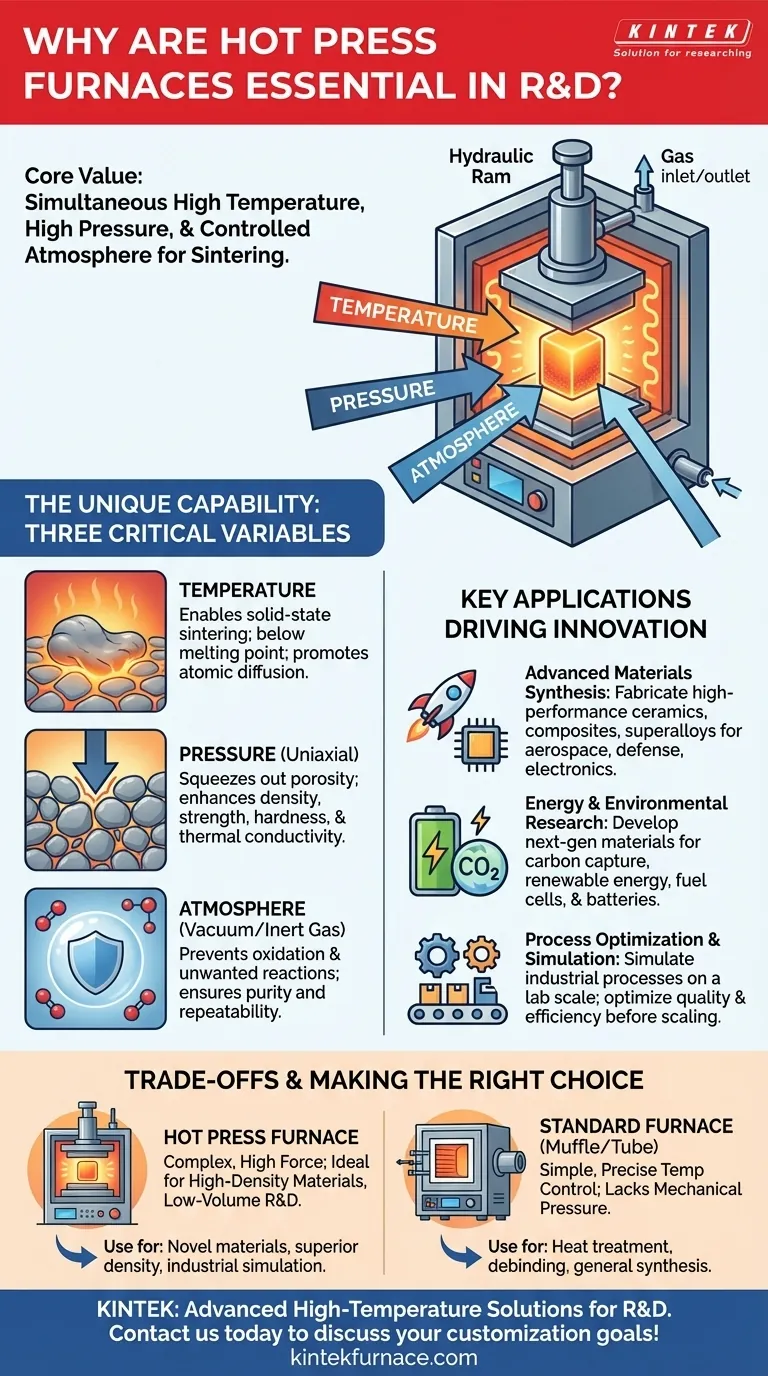

The Unique Capability: Combining Heat, Pressure, and Atmosphere

The power of a hot press furnace comes from the precise interplay of three critical variables. Each serves a distinct purpose in transforming loose powders into a high-performance solid.

The Role of Temperature

High heat makes the individual grains of a material more malleable and encourages atomic diffusion across their boundaries.

Crucially, this is often done below the material's melting point, a process called solid-state sintering. This avoids the problems associated with casting, such as shrinkage, cracking, and undesirable microstructures.

The Critical Impact of Pressure

While heat makes the material workable, the uniaxial pressure applied by the press is what physically forces the grains together.

This mechanical force is highly effective at squeezing out the voids (porosity) between particles. The result is an exceptionally dense material with significantly improved mechanical strength, hardness, and thermal conductivity.

The Importance of a Controlled Atmosphere

Many advanced materials are highly reactive with oxygen, especially at high temperatures. Performing the process in a vacuum or an inert gas (like argon) prevents oxidation and other unwanted chemical reactions.

This ensures the purity of the final material and guarantees that its properties are a direct result of the intended composition and structure, providing precise and repeatable results for research.

Key Applications Driving Innovation

This combination of heat, pressure, and atmospheric control makes hot press furnaces indispensable for pushing the boundaries in several key scientific fields.

Advanced Materials Synthesis

Hot pressing is a cornerstone of modern materials science. It is used to fabricate high-performance ceramics, metal-matrix composites, and superalloys that are lighter, stronger, and more heat-resistant than conventional materials.

These advanced materials are critical for applications in aerospace, defense, and cutting-edge electronics.

Energy and Environmental Research

Researchers use hot press furnaces to develop next-generation materials for a sustainable future.

This includes developing novel materials for carbon capture, testing biomass pyrolysis for renewable energy production, and preparing and testing durable components for fuel cells and next-generation batteries.

Process Optimization and Simulation

Instead of running expensive and time-consuming trials on a full production line, R&D labs use hot presses to simulate industrial manufacturing processes.

They can rapidly test different temperature profiles, pressure levels, and cycle times to optimize a process for quality and efficiency before scaling it up.

Understanding the Trade-offs and Distinctions

While powerful, a hot press furnace is a specialized tool. Understanding its role relative to other thermal equipment is key to appreciating its value.

Hot Press vs. Standard Furnaces (Muffle/Tube)

Standard muffle or tube furnaces are excellent for providing precise temperature control in a regulated atmosphere. They are used for processes like annealing, heat treatment, and some types of material synthesis.

However, they lack the critical component of applied mechanical pressure. They cannot achieve the high levels of densification that are the primary advantage of a hot press.

The Role of Simplicity and Cost

Hot press systems are significantly more complex and expensive to operate than standard furnaces. They require robust frameworks to handle the high forces involved and sophisticated control systems.

This complexity makes them ideal for cutting-edge R&D and the production of low-volume, high-value components, but less practical for general-purpose heat treatment or mass production.

Making the Right Choice for Your Research

Choosing the correct thermal processing equipment depends entirely on the scientific or engineering goal.

- If your primary focus is creating new, high-density materials with superior mechanical properties: A hot press furnace is essential for its ability to combine heat and uniaxial pressure to eliminate porosity.

- If your primary focus is heat treatment, debinding, or material synthesis where maximum density is not the goal: A simpler and more cost-effective tube or muffle furnace is often the more appropriate tool.

- If your primary focus is simulating an industrial compaction process at a lab scale: A hot press provides the necessary parameters to test and optimize the manufacturing cycle before full-scale implementation.

Ultimately, the hot press furnace empowers researchers with a fundamental tool to build stronger, purer, and more advanced materials from the atomic level up.

Summary Table:

| Variable | Role in Hot Press Furnace |

|---|---|

| Temperature | Enables malleability and atomic diffusion below melting point for solid-state sintering |

| Pressure | Applies uniaxial force to eliminate porosity, enhancing density and mechanical properties |

| Atmosphere | Uses vacuum or inert gas to prevent oxidation, ensuring material purity and repeatability |

Ready to elevate your R&D with tailored high-temperature solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced hot press furnaces and other systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for creating novel materials with superior density and performance. Contact us today to discuss how we can support your innovation goals!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What is a vacuum hot press furnace? Unlock Superior Material Performance