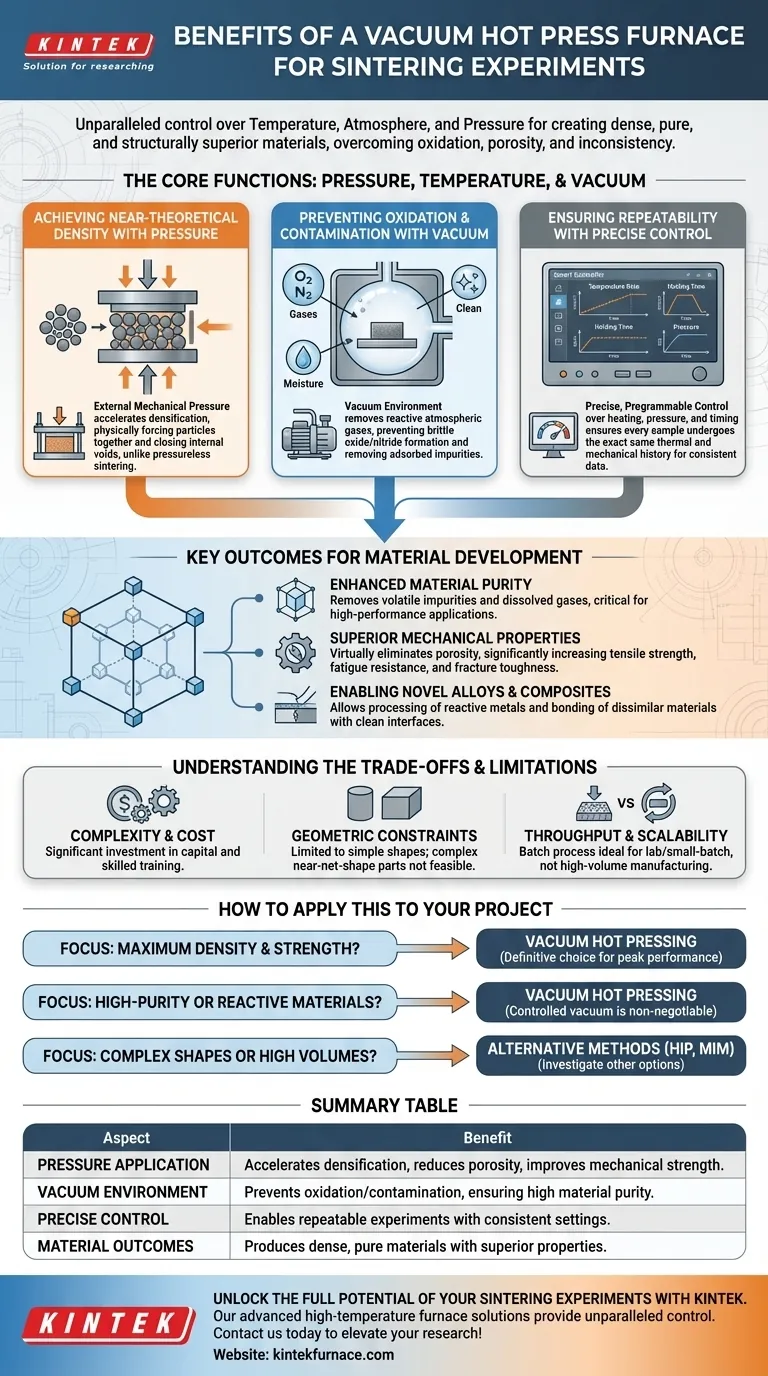

In essence, a vacuum hot press furnace provides an unparalleled level of control over the three most critical variables in sintering: temperature, atmosphere, and pressure. This combination allows for the creation of dense, pure, and structurally superior materials that are often impossible to achieve with conventional atmospheric furnaces. It solves the fundamental problems of oxidation, porosity, and inconsistent results that plague many advanced material experiments.

The core challenge in sintering is fusing powder particles into a solid mass without defects. A vacuum hot press furnace addresses this directly by using a clean vacuum to prevent contamination while simultaneously applying mechanical pressure to physically force the material into a dense state.

The Core Functions: Unpacking Pressure, Temperature, and Vacuum

A vacuum hot press is not just a furnace; it is a highly controlled processing environment. Understanding how its core functions work together is key to appreciating its benefits for experimental work.

Achieving Near-Theoretical Density with Pressure

Sintering relies on atomic diffusion to bond particles and eliminate the gaps, or pores, between them.

Applying external mechanical pressure dramatically accelerates this process. It physically forces particles closer together, closes off internal voids, and promotes the diffusion mechanisms that lead to densification.

This is a significant advantage over conventional "pressureless" sintering, which relies solely on heat and can often leave residual porosity, weakening the final material.

Preventing Oxidation and Contamination with Vacuum

Many advanced materials, particularly metals like titanium or certain ceramics, are highly reactive with oxygen and nitrogen at sintering temperatures.

Creating a vacuum environment removes these reactive atmospheric gases. This prevents the formation of brittle oxide or nitride layers on the particle surfaces, which would inhibit proper bonding and degrade the final properties.

This clean environment also removes adsorbed gases and moisture from the initial powder, leading to higher purity and improved wettability in liquid-phase sintering.

Ensuring Repeatability with Precise Control

Scientific experiments demand consistency. The furnace's integrated systems allow for precise, programmable control over the heating rate, final temperature, holding time, and applied pressure.

This ensures that every sample is subjected to the exact same thermal and mechanical history. This level of control is critical for minimizing grain growth, controlling phase transformations, and producing reliable, repeatable data for analysis.

Key Outcomes for Material Development

The precise control over the sintering environment translates directly into superior material outcomes that are critical for research and development.

Enhanced Material Purity

The combination of high heat and vacuum acts as a refining process. It helps to remove volatile impurities and dissolved gases like hydrogen and oxygen from the material.

The resulting high-purity material is essential for applications where even trace contaminants can degrade electrical, optical, or mechanical performance.

Superior Mechanical Properties

The end goal of sintering is often a material with optimal strength and durability.

By virtually eliminating porosity and preventing weak, brittle oxide inclusions, vacuum hot pressing produces materials with significantly higher tensile strength, fatigue resistance, and fracture toughness. The final part is dense, clean, and structurally sound.

Enabling Novel Alloys and Composites

This technology opens the door to materials that could not otherwise be fabricated.

It is indispensable for processing reactive metals and alloys, or for creating composites by bonding dissimilar materials that require an impeccably clean interface to form a strong bond.

Understanding the Trade-offs and Limitations

While powerful, a vacuum hot press is not a universal solution. An objective assessment requires understanding its limitations.

Complexity and Cost

These are sophisticated and expensive pieces of equipment. They require skilled operators to manage the vacuum systems, pressure controls, and programming, representing a significant investment in both capital and training.

Geometric Constraints

The use of a uniaxial press (pushing from one or two directions) means that hot pressing is typically limited to producing relatively simple shapes, such as cylinders, discs, and rectangular blocks. Complex, near-net-shape parts are not feasible with this method.

Throughput and Scalability

Vacuum hot pressing is fundamentally a batch process. While ideal for laboratory-scale experiments and small-batch production of high-value components, it is not well-suited for high-volume, continuous manufacturing.

How to Apply This to Your Project

Your choice of sintering method should be driven by the ultimate goal of your experiment or product.

- If your primary focus is maximum density and mechanical performance: Vacuum hot pressing is the definitive choice for eliminating porosity and achieving peak material strength.

- If your primary focus is creating high-purity or reactive materials: The controlled vacuum atmosphere is non-negotiable, making this furnace a leading option.

- If your primary focus is producing complex shapes or high volumes: You should investigate alternative methods like Hot Isostatic Pressing (HIP) or powder injection molding, as the geometric and batch limitations of a hot press may be prohibitive.

Ultimately, mastering your material's properties begins with mastering its processing environment.

Summary Table:

| Aspect | Benefit |

|---|---|

| Pressure Application | Accelerates densification, reduces porosity, and improves mechanical strength. |

| Vacuum Environment | Prevents oxidation and contamination, ensuring high material purity. |

| Precise Control | Enables repeatable experiments with consistent temperature and pressure settings. |

| Material Outcomes | Produces dense, pure materials with superior mechanical properties for advanced applications. |

Unlock the Full Potential of Your Sintering Experiments with KINTEK

Struggling with oxidation, porosity, or inconsistent results in your material development? KINTEK's advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, are designed to provide unparalleled control over temperature, pressure, and atmosphere. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs, whether you're working with reactive metals, ceramics, or novel composites. Achieve superior density, purity, and repeatability in your lab—contact us today to discuss how our tailored furnace systems can elevate your research and drive innovation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%