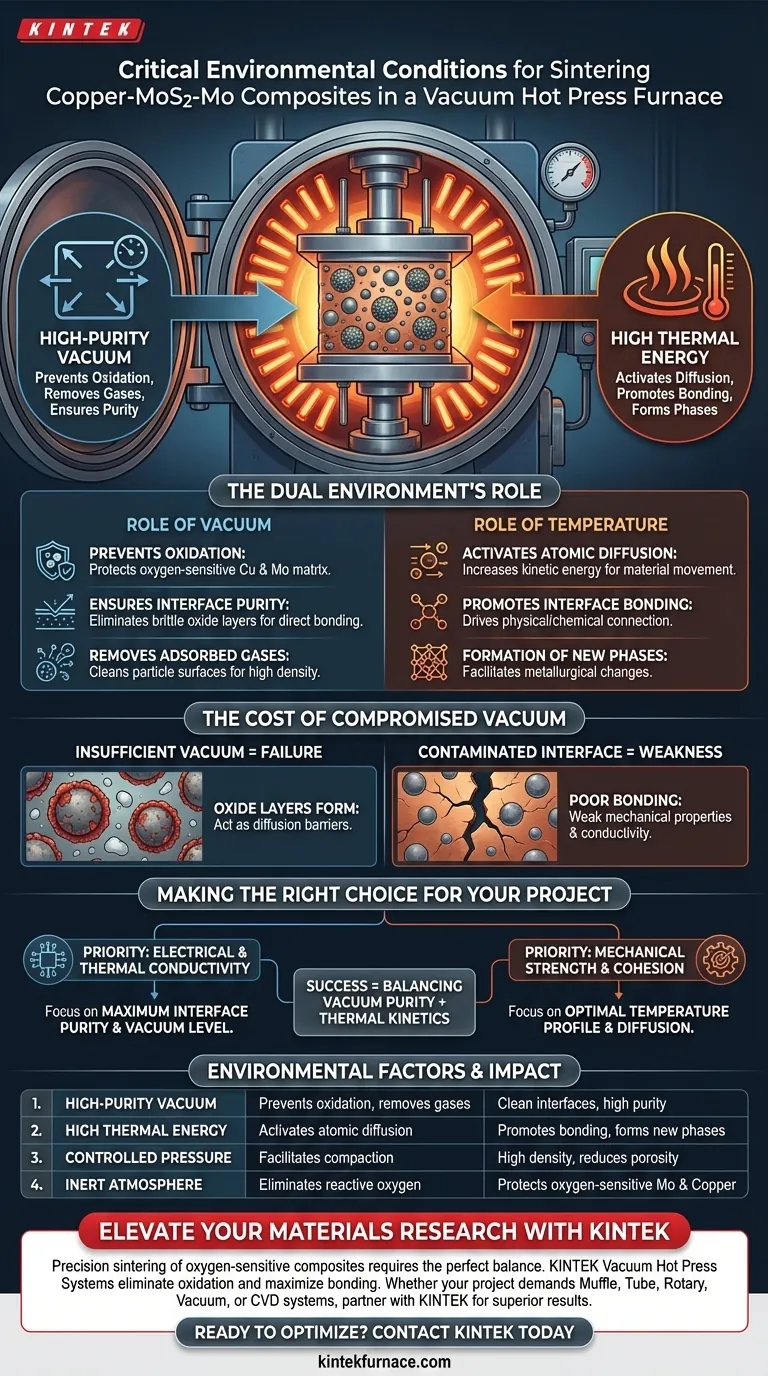

A vacuum hot press furnace creates a critical dual environment consisting of high thermal energy and a high-purity vacuum. For dispersion copper-MoS2-Mo composites, this specific combination is required to prevent the oxidation of the copper matrix and oxygen-sensitive molybdenum powder, ensuring a clean interface while driving the atomic diffusion necessary for bonding.

Core Takeaway The integrity of copper-MoS2-Mo composites relies on the simultaneous exclusion of oxygen and application of heat. The vacuum environment preserves material purity by preventing oxidation, while high temperature activates the atomic mechanisms required to bond the matrix with reinforcement phases.

The Role of the High Vacuum Environment

Prevention of Material Oxidation

The most immediate function of the vacuum environment is the protection of the raw materials.

Specifically, it prevents the oxidation of the copper matrix, which acts as the base material.

Crucially, it protects the molybdenum powder, which is explicitly noted as being oxygen-sensitive.

Ensuring Interface Purity

By eliminating oxygen from the chamber, the furnace ensures the purity of the internal interfaces.

Oxidation typically creates brittle layers or barriers between particles.

Removing this threat allows for a direct, clean interaction between the copper and the reinforcement phases.

Removal of Adsorbed Gases

While the primary focus is preventing new oxidation, the vacuum also helps manage existing surface contaminants.

The low-pressure environment effectively removes gases that may be adsorbed onto the surface of the powder particles.

This "cleaning" action is a prerequisite for achieving high-density material without gas pockets or weak spots.

The Role of High Temperature

Activating Atomic Diffusion

High temperature acts as the catalyst for movement within the material.

It activates atomic diffusion, increasing the kinetic energy of atoms within the copper and molybdenum.

This movement is essential for moving material from a loose powder state to a solid, cohesive composite.

Promoting Interface Bonding

The heat drives the physical and chemical connection between the matrix (copper) and the reinforcement phases.

This ensures that the reinforcing particles are not just sitting in the copper, but are structurally bonded to it.

Formation of New Phases

The thermal environment facilitates metallurgical changes beyond simple bonding.

The primary reference notes that this heat promotes the formation of new phases, which can be critical for tailoring the specific properties of the composite.

Common Pitfalls: The Cost of Compromised Vacuum

The Barrier of Oxide Layers

If the vacuum level is insufficient, oxide layers will inevitably form on particle surfaces.

These layers act as a diffusion barrier, physically blocking the atomic movement described above.

Weakened Mechanical Properties

Even minor oxidation can degrade the "interface purity" that the vacuum is designed to protect.

A contaminated interface results in poor bonding between the copper and the molybdenum, leading to a composite that may fail under stress or exhibit poor conductivity.

Making the Right Choice for Your Project

To optimize the sintering of copper-MoS2-Mo composites, prioritize your process parameters based on the desired material outcome:

- If your primary focus is electrical and thermal conductivity: Prioritize maintaining a high-level vacuum to ensure maximum interface purity and prevent oxide barriers that impede electron flow.

- If your primary focus is mechanical strength and cohesion: Ensure the temperature profile is sufficient to fully activate atomic diffusion and promote the formation of strengthening phases.

Success in sintering this composite is defined by balancing the purity provided by the vacuum with the kinetic activity driven by the temperature.

Summary Table:

| Environmental Factor | Primary Function | Impact on Composite |

|---|---|---|

| High-Purity Vacuum | Prevents oxidation & removes adsorbed gases | Ensures clean interfaces & high material purity |

| High Thermal Energy | Activates atomic diffusion | Promotes bonding and the formation of new phases |

| Controlled Pressure | Facilitates particle compaction | Achieves high density and reduces porosity |

| Inert Atmosphere | Eliminates reactive oxygen | Protects oxygen-sensitive Mo and Copper matrix |

Elevate Your Materials Research with KINTEK

Precision sintering of oxygen-sensitive composites like Copper-MoS2-Mo requires the perfect balance of vacuum purity and thermal control. KINTEK provides industry-leading Vacuum Hot Press Systems designed to eliminate oxidation and maximize interface bonding through advanced R&D and precision manufacturing.

Whether your project demands Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temp lab furnaces are fully customizable to meet your specific research or production requirements. Partner with KINTEK to achieve superior density and mechanical strength in your next composite project.

Ready to optimize your sintering process? Contact KINTEK today for a custom solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the core advantages of using a vacuum hot press furnace? Achieve Near-Forged Density for Ti-6Al-4V Alloys

- What is a vacuum press machine? Achieve Perfect, Void-Free Lamination and Densification

- What are the different types of heating methods in vacuum hot press sintering furnaces? Compare Resistance vs. Induction

- Why are Carbon Fiber Reinforced Composite (CFRC) plates used in SPS? Optimize Thermal Stability in Sintering

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How does the vacuum system in these furnaces work? Achieve Purity and Performance in High-Temperature Processes

- How does a hot press machine work? Master Heat, Pressure, and Time for Perfect Results