At its core, a hot press machine works by using a heated plate, known as a platen, to apply both high temperature and significant pressure to a substrate. This controlled combination of heat and force is used to permanently transfer a design or to fuse materials together. The process relies on three critical components working in unison: a heating element to generate the heat, the platen to distribute it evenly, and a mechanical system to apply consistent pressure.

A hot press is not simply a source of heat. It is a precision tool designed to control the interplay of heat, pressure, and time—the three fundamental variables that determine the success or failure of any transfer or material bonding process.

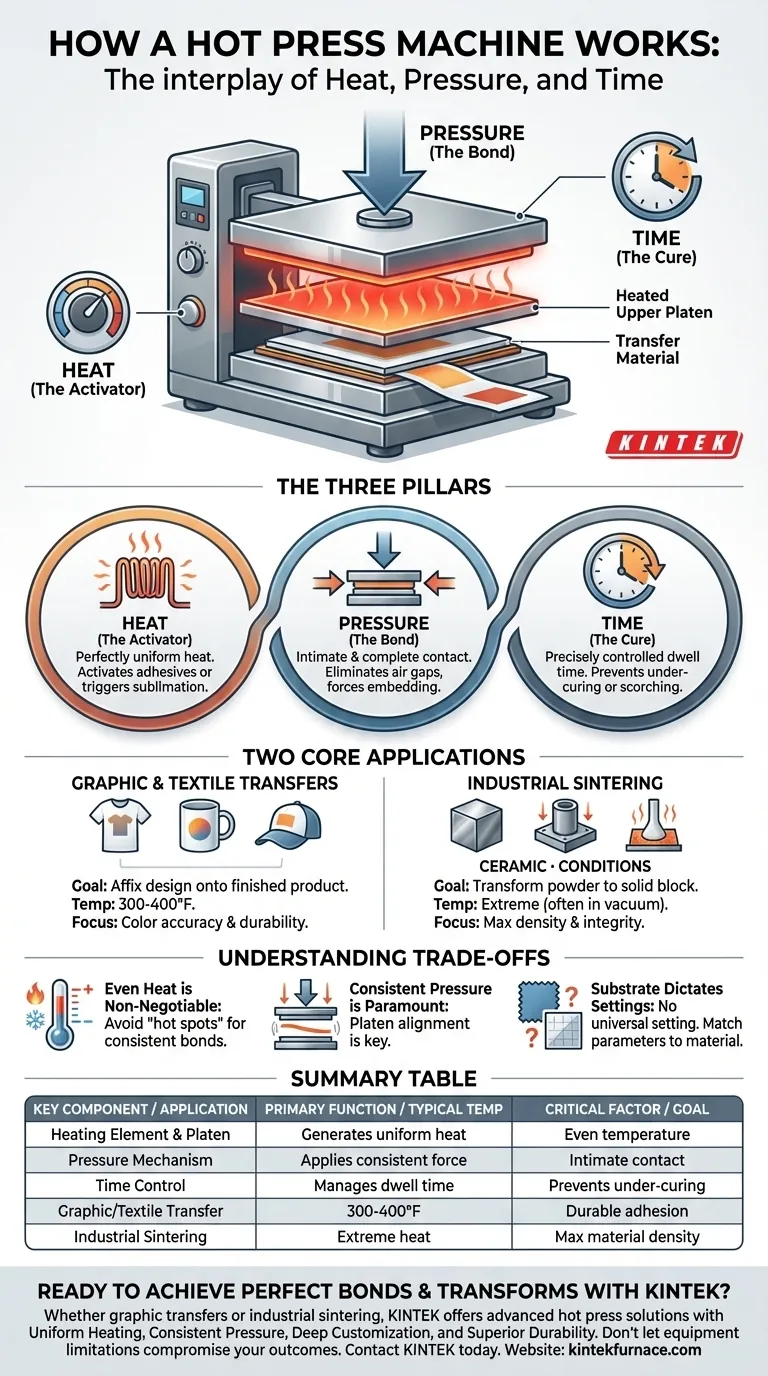

The Three Pillars of Hot Pressing

To truly understand how a hot press works, you must see it as a system for managing three distinct but interconnected factors. Each one plays a crucial role in the final outcome.

The Role of Heat (The Activator)

The process begins with the internal heating element, which warms the metal platen. This platen’s most important job is to provide perfectly uniform heat across its entire surface.

This heat acts as an activator. In graphic transfers, it might activate special adhesives on the back of heat transfer vinyl (HTV) or trigger sublimation, where solid ink turns directly into a gas to dye the fibers of a substrate.

The Role of Pressure (The Bond)

The pressure mechanism, which can be a manual lever or an automated pneumatic system, is what ensures intimate and complete contact.

This force presses the transfer medium (like paper or vinyl) firmly against the substrate (like a t-shirt or ceramic tile). It eliminates air gaps and forces the activated ink or adhesive to physically embed itself into the surface or fibers of the material, creating a permanent bond that resists peeling and fading.

The Role of Time (The Cure)

Time is the element that allows the heat and pressure to do their work effectively. The duration of the press, known as "dwell time," is precisely controlled.

Too little time, and the transfer will be incomplete, resulting in a weak bond. Too much time, and you risk scorching the substrate, burning the adhesive, or causing the colors in the design to bleed or fade.

Two Core Applications: Transfer vs. Transformation

While the principles are the same, hot presses are used for two very different scales of application.

Application 1: Graphic and Textile Transfers

This is the most common use, seen in creating custom apparel, mugs, signs, and other promotional items. The goal is to affix a separate design layer onto a finished product.

Here, temperatures are typically in the range of 300-400°F (150-200°C). The focus is on color accuracy and the durability of the transfer through washing and use.

Application 2: Industrial Material Sintering

In advanced manufacturing, hot pressing is used for a process called sintering. This involves transforming powdered materials, like ceramics or metal alloys, into a solid, incredibly dense block.

Here, immense pressure and extreme temperatures are applied in a vacuum or an inert gas environment. The force compacts the powder while the heat fuses the particles together, creating a final product with near-perfect density and superior material properties.

Understanding the Trade-offs

The effectiveness of a hot press is not guaranteed by its existence alone. The quality of the components and their application create significant trade-offs.

Even Heat is Non-Negotiable

A common failure point in lower-quality machines is the presence of "hot spots" or cold spots on the platen. An uneven temperature will result in a transfer that is perfectly bonded in one area and faded or peeling in another.

Consistent Pressure is Paramount

The pressure must be applied evenly across the entire surface. If the platen wobbles or is misaligned, the pressure will be greater on one side, leading to an inconsistent and unprofessional result. This is a key differentiator between well-engineered machines and their cheaper counterparts.

The Substrate Dictates the Settings

There is no universal setting. A cotton shirt requires a different combination of heat, pressure, and time than a polyester performance garment or a hard ceramic tile. Using the wrong settings for your specific substrate is the most common source of error.

Making the Right Choice for Your Goal

Understanding the core principles allows you to focus on what matters for your specific application.

- If your primary focus is crafting and apparel: Prioritize a machine known for excellent heat consistency across the platen and learn the specific settings required for your chosen transfer materials.

- If your primary focus is industrial manufacturing: Your concerns are achieving maximum material density and integrity, which requires precise control over temperature ramps, atmospheric conditions, and immense, quantifiable pressure.

Mastering a hot press comes from understanding that you are not just operating a machine; you are controlling a fundamental material transformation.

Summary Table:

| Key Component | Primary Function | Critical Factor |

|---|---|---|

| Heating Element & Platen | Generates and distributes uniform heat | Even temperature across the entire surface |

| Pressure Mechanism | Applies consistent force for bonding | Intimate contact without air gaps |

| Time Control | Manages the duration of the press cycle | Prevents under-curing or scorching |

| Application | Typical Temperature Range | Goal |

| Graphic/Textile Transfer | 300-400°F (150-200°C) | Durable, color-accurate adhesion |

| Industrial Sintering | Extreme heat (often in a vacuum) | Maximum material density and integrity |

Ready to Achieve Perfect Bonds and Transforms?

Whether your project requires the precision of graphic transfers or the robust performance of industrial sintering, the right equipment is critical. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced hot press solutions.

Our expertise ensures:

- Uniform Heating & Consistent Pressure: Eliminate hot spots and uneven bonds for flawless results every time.

- Deep Customization: We tailor our machines to your unique material and process requirements.

- Superior Durability: Built for reliability in both craft and demanding industrial environments.

Don't let equipment limitations compromise your outcomes. Contact KINTEL today to discuss how our hot press solutions can transform your production process.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%