At its core, a vacuum press is a specialized machine that uses a combination of vacuum and pressure to laminate, bond, or densify materials. By removing air from a sealed chamber or bag, it allows for the application of perfectly uniform pressure, resulting in a bond or form that is free of voids and defects. For applications requiring heat, a vacuum hot press integrates a heating system to achieve specific material properties like increased density or mechanical strength.

The fundamental advantage of a vacuum press is its ability to create a controlled, low-pressure environment. This prevents contamination and ensures that pressure is applied evenly across the entire surface of a material, achieving a level of quality and consistency that is often impossible with conventional mechanical presses.

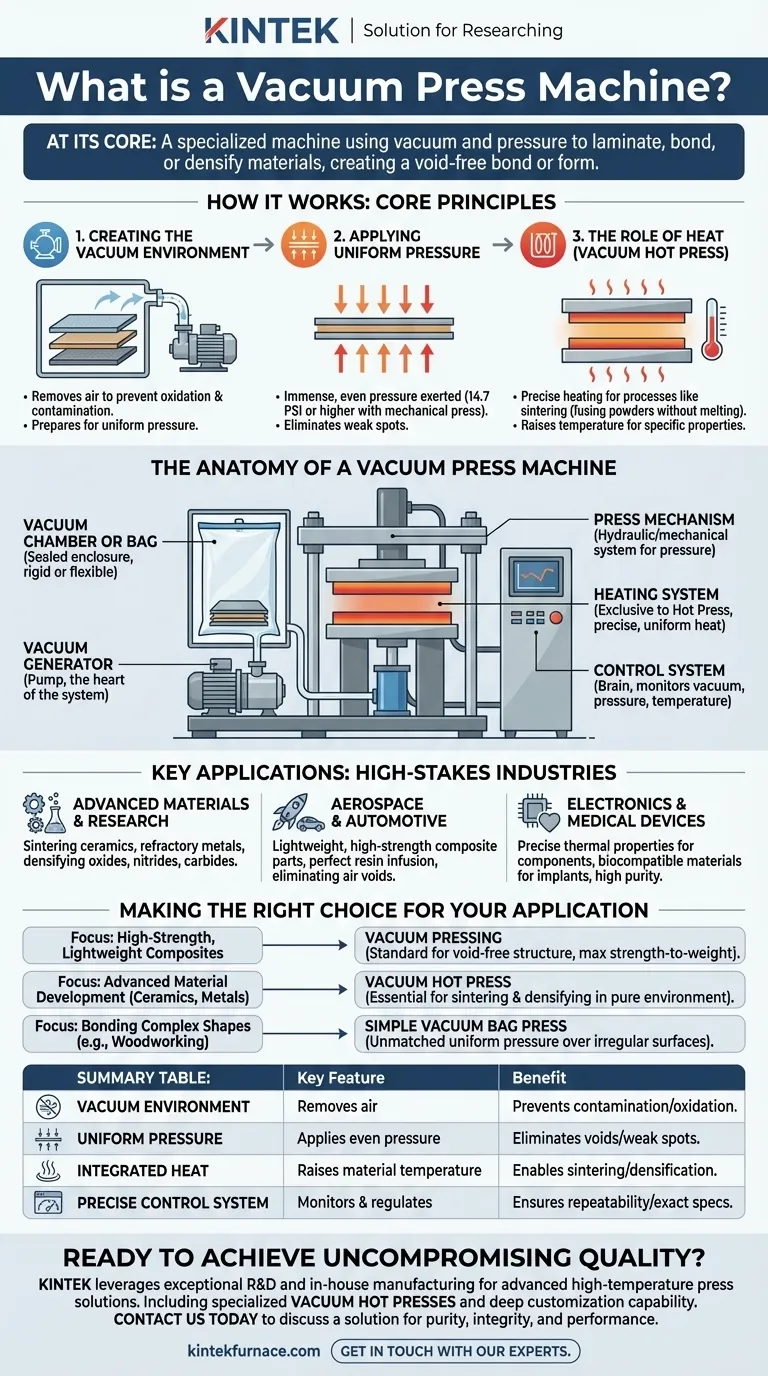

How a Vacuum Press Works: The Core Principles

A vacuum press operates on a simple yet powerful concept. By manipulating atmospheric pressure and temperature in a controlled space, it fundamentally changes how materials can be shaped and bonded together.

Creating the Vacuum Environment

The process begins by placing the materials inside a sealed vacuum chamber or a flexible vacuum bag. A vacuum generator, or pump, then evacuates the air and other gases from this sealed environment.

This step is critical for two reasons. First, it prevents oxidation and contamination of the materials, which is crucial when working with sensitive metals or composites at high temperatures. Second, it prepares the stage for uniform pressure application.

Applying Uniform Pressure

Once a vacuum is established, immense and even pressure is exerted on the material. In a simple bag press, this is the surrounding atmospheric pressure (about 14.7 PSI at sea level) pushing down evenly on every square inch of the object.

In more advanced vacuum hot presses, a mechanical press mechanism works in tandem with the vacuum to apply even greater, highly controlled forces. This uniformity eliminates weak spots and ensures a consistent bond or density throughout the material.

The Role of Heat (in a Hot Press)

For many advanced applications, pressure alone is not enough. A vacuum hot press integrates a sophisticated heating system, often using resistance or induction elements, to raise the material's temperature with extreme precision.

This combination of heat, pressure, and a pure vacuum environment is essential for processes like sintering, where powdered materials (like ceramics or metals) are fused into a solid, dense mass without melting.

The Anatomy of a Vacuum Press Machine

While designs vary, all vacuum presses share several key components that work in concert to achieve a precise outcome.

The Vacuum Chamber or Bag

This is the sealed enclosure where the work takes place. It can be a rigid steel chamber for high-temperature industrial processes or a flexible polymer bag for woodworking and composite lamination.

The Vacuum Generator

This pump is the heart of the system, responsible for removing air to create the necessary low-pressure environment.

The Press Mechanism

In heavy-duty hot presses, this is the hydraulic or mechanical system that applies immense, controlled pressure to the materials inside the chamber.

The Heating System

Exclusive to hot presses, this system provides precise and uniform heat. Its design is critical for ensuring materials reach the target temperature consistently without hot spots.

The Control System

This is the brain of the machine. A modern control system monitors and regulates vacuum levels, pressure, and temperature throughout the process, ensuring the final product meets exact specifications.

Understanding the Key Applications

The unique capabilities of vacuum pressing make it an indispensable tool across several high-stakes industries.

Advanced Materials and Research

Vacuum hot presses are vital for creating advanced materials with enhanced properties. This includes sintering industrial ceramics, refractory metals, and densifying materials like oxides, nitrides, and carbides for use in cutting tools or wear-resistant coatings.

Aerospace and Automotive

In these industries, the focus is on creating lightweight, high-strength components. Vacuum pressing is used to manufacture composite parts, ensuring perfect resin infusion and eliminating air voids that could lead to catastrophic failure.

Electronics and Medical Devices

The clean, controlled environment of a vacuum press is perfect for producing electronic components with precise thermal properties or fabricating biocompatible materials for medical implants where purity and structural integrity are non-negotiable.

Making the Right Choice for Your Application

Understanding the process helps clarify when to employ this technology. Your decision should be guided by the required quality and material properties of the final product.

- If your primary focus is producing high-strength, lightweight composites: Vacuum pressing is the standard for ensuring a void-free structure with maximum strength-to-weight ratio.

- If your primary focus is advanced material development (ceramics, metals): A vacuum hot press is essential for sintering and densifying powdered materials in a pure, controlled environment to achieve superior hardness and thermal resistance.

- If your primary focus is bonding or veneering complex shapes (e.g., in woodworking): A simple vacuum bag press offers an unmatched ability to apply perfectly uniform pressure over irregular surfaces.

Ultimately, a vacuum press is the tool of choice when material integrity, purity, and performance cannot be compromised.

Summary Table:

| Key Feature | Function | Benefit |

|---|---|---|

| Vacuum Environment | Removes air from a sealed chamber or bag. | Prevents contamination and oxidation for pure material processing. |

| Uniform Pressure | Applies even pressure across the entire material surface. | Eliminates voids and weak spots for consistent, high-quality results. |

| Integrated Heat (Hot Press) | Precisely raises material temperature. | Enables sintering and densification of advanced materials like ceramics and metals. |

| Precise Control System | Monitors and regulates vacuum, pressure, and temperature. | Ensures repeatable processes and exact material specifications are met. |

Ready to Achieve Uncompromising Quality in Your Materials?

Whether you are developing advanced ceramics, manufacturing high-strength aerospace composites, or bonding complex shapes, the right vacuum press is critical to your success. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature press solutions.

Our product line, including specialized Vacuum Hot Presses, is complemented by our strong deep customization capability to precisely meet your unique experimental and production requirements.

Contact us today to discuss how we can engineer a vacuum press solution that delivers the purity, integrity, and performance your materials demand.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

People Also Ask

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials