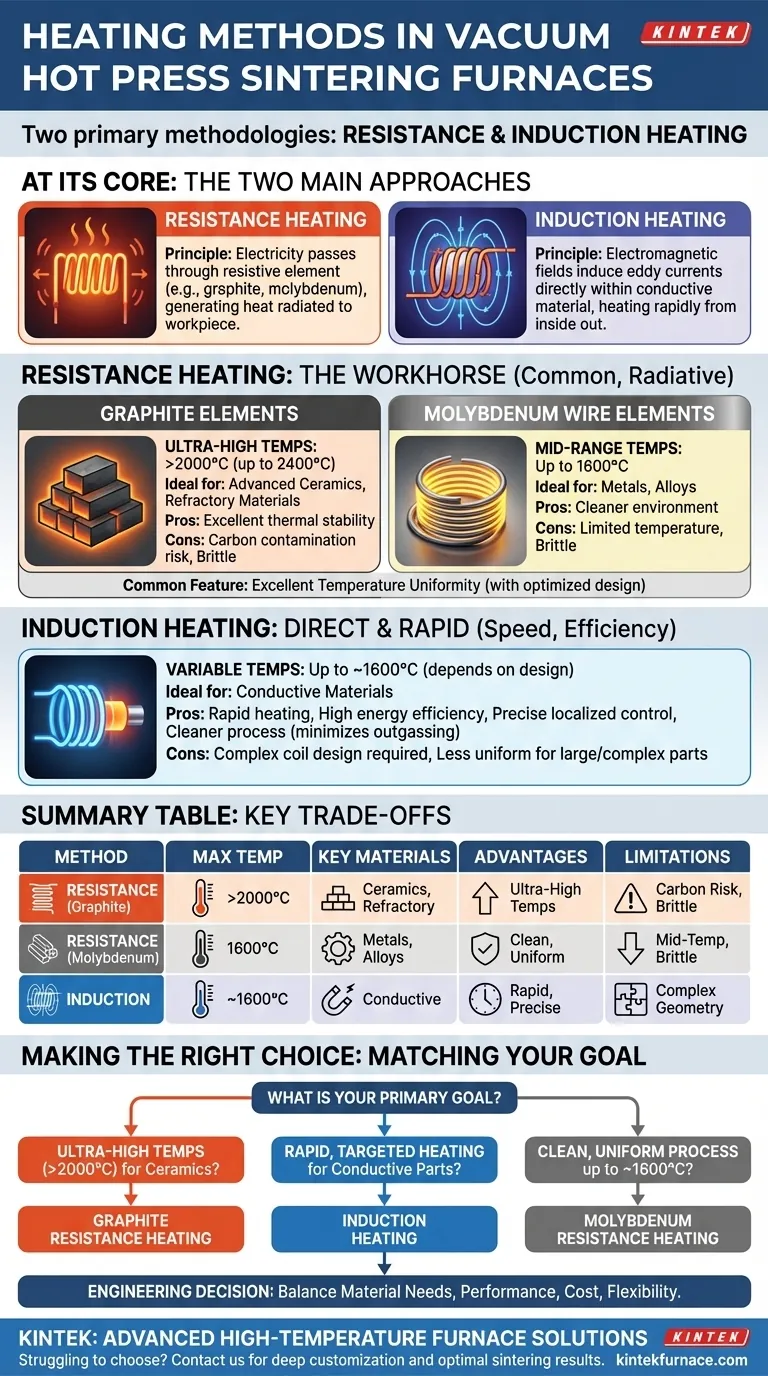

At its core, a vacuum hot press sintering furnace primarily uses two distinct heating methodologies: resistance heating and induction heating. Resistance heating generates heat by passing an electrical current through a resistive element, such as graphite or molybdenum wire, which then radiates heat to the workpiece. Induction heating uses electromagnetic fields to directly and rapidly generate heat within the conductive material itself.

The choice between heating methods is not about which is universally superior, but which is strategically aligned with your specific material, required processing temperature, and sensitivity to contamination. Understanding this relationship is the key to successful sintering.

The Primary Heating Methods Explained

The heating method is the heart of the furnace, directly influencing processing time, temperature uniformity, and the final properties of your component. The two main approaches serve different operational needs.

Resistance Heating: The Workhorse Method

Resistance heating is the most common method, relying on the simple principle of passing electricity through a material that resists the flow, generating heat. This heat is then radiated throughout the furnace chamber.

The specific material used for the heating element is a critical decision.

Graphite Elements

Graphite is the go-to choice for achieving ultra-high temperatures, often exceeding 2000°C and up to 2400°C. Its excellent thermal stability makes it ideal for sintering advanced ceramics and other refractory materials.

Molybdenum Wire Elements

Molybdenum (often as molybdenum wire) is used for mid-range temperature applications, typically up to 1600°C. Its primary advantage is providing a cleaner heating environment compared to graphite, which can introduce carbon.

Induction Heating: Direct and Rapid

Induction heating operates on a completely different principle. It uses an induction coil to create a powerful, alternating electromagnetic field around the workpiece.

This field induces electrical currents (eddy currents) directly within the conductive material, causing it to heat up rapidly from the inside out. This is often referred to as medium-frequency heating in technical specifications.

The key advantage here is speed and efficiency, as energy is transferred directly to the part rather than heating the entire furnace chamber first.

Matching the Method to Your Operational Needs

Selecting the right heating system requires balancing three key factors: the target temperature, the material being processed, and the need for process control.

Required Sintering Temperature

The single most important factor is your maximum required temperature. This will immediately narrow your options.

- Ultra-High Temperatures (>1800°C): Graphite resistance heating is effectively the only choice for processes requiring temperatures in the 2000-2400°C range.

- Mid-to-High Temperatures (up to 1600°C): Molybdenum resistance heating offers a clean and stable environment for a wide range of materials.

- Variable & Rapid Heating: Induction heating excels where speed is critical, though its temperature ceiling depends on the coil and workpiece design.

Material Properties and Contamination

The furnace atmosphere and heating elements can interact with your material.

Graphite elements can introduce carbon into the furnace atmosphere, which may be undesirable for certain alloys but can be beneficial for others (like carbides).

Induction heating only heats the conductive part, minimizing outgassing from furnace insulation and offering a cleaner process, provided the workpiece itself is conductive.

Heating Uniformity and Control

Achieving a uniform temperature is critical for consistent densification and preventing internal stresses.

Resistance furnaces with optimized element distribution and robust insulation (often made of graphite felt) are designed to provide excellent temperature uniformity across a large volume.

Induction heating provides highly localized and precise control, which is ideal for specific geometries but can pose a challenge for achieving uniformity across large or complex-shaped parts without careful coil design.

Understanding the Trade-offs

Each method comes with inherent limitations that you must consider for long-term operation and maintenance.

Resistance Heating: Lifespan and Brittleness

Heating elements are consumables. Both graphite and molybdenum elements have a finite lifespan and become brittle over time, requiring periodic replacement. This should be factored into your operational costs and maintenance schedule.

Induction Heating: Complexity and Specificity

The primary trade-off for induction heating's speed is its complexity. The induction coil must often be designed and tuned for a specific part geometry to ensure efficient and uniform heating. This makes it less flexible for running a wide variety of different parts compared to a resistance furnace.

The Risk of Carbon Contamination

When using graphite resistance elements, you must always account for the carbon-rich environment. This is a critical failure point for processing oxygen-sensitive materials or alloys where carbon pickup would be detrimental to their final properties.

Making the Right Choice for Your Goal

Your application's primary driver will dictate the best heating technology.

- If your primary focus is reaching ultra-high temperatures (>2000°C) for ceramics or refractory metals: Graphite resistance heating is the necessary and most effective choice.

- If your primary focus is rapid, targeted heating of conductive parts with high process control: Induction heating offers unmatched speed and energy efficiency.

- If your primary focus is a clean, uniform process for metals and alloys up to ~1600°C: Molybdenum resistance heating provides an excellent balance of performance and purity.

Ultimately, choosing the right heating method is an engineering decision that balances your material's needs against the performance, cost, and flexibility of the technology.

Summary Table:

| Heating Method | Max Temperature | Key Materials | Primary Advantages | Key Limitations |

|---|---|---|---|---|

| Resistance (Graphite) | Up to 2400°C | Advanced ceramics, refractory materials | Ultra-high temperatures, excellent thermal stability | Carbon contamination risk, brittle elements |

| Resistance (Molybdenum) | Up to 1600°C | Metals, alloys | Clean environment, good temperature uniformity | Limited to mid-range temperatures, brittle elements |

| Induction | Variable, up to ~1600°C | Conductive materials | Rapid heating, high efficiency, precise control | Requires specific part geometry, less uniform for large parts |

Struggling to choose the right heating method for your vacuum hot press sintering furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're processing ceramics, metals, or other materials, we can help you achieve optimal sintering results. Contact us today to discuss your project and discover how our expertise can enhance your lab's efficiency and success!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- What are the applications of hot pressing? Achieve Maximum Material Performance

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density