At its core, a furnace's vacuum system is an advanced air pump. It is designed to remove air, moisture, and other reactive gases from a sealed chamber before and during a high-temperature process. This is accomplished using a series of specialized pumps that can achieve extremely low pressures, while gauges and valves provide precise monitoring and control over this environment.

The true purpose of a vacuum system isn't simply to create emptiness; it's to engineer a chemically pure environment. By removing reactive gases like oxygen, the system enables high-temperature material processing without the contamination and oxidation that would occur in open air.

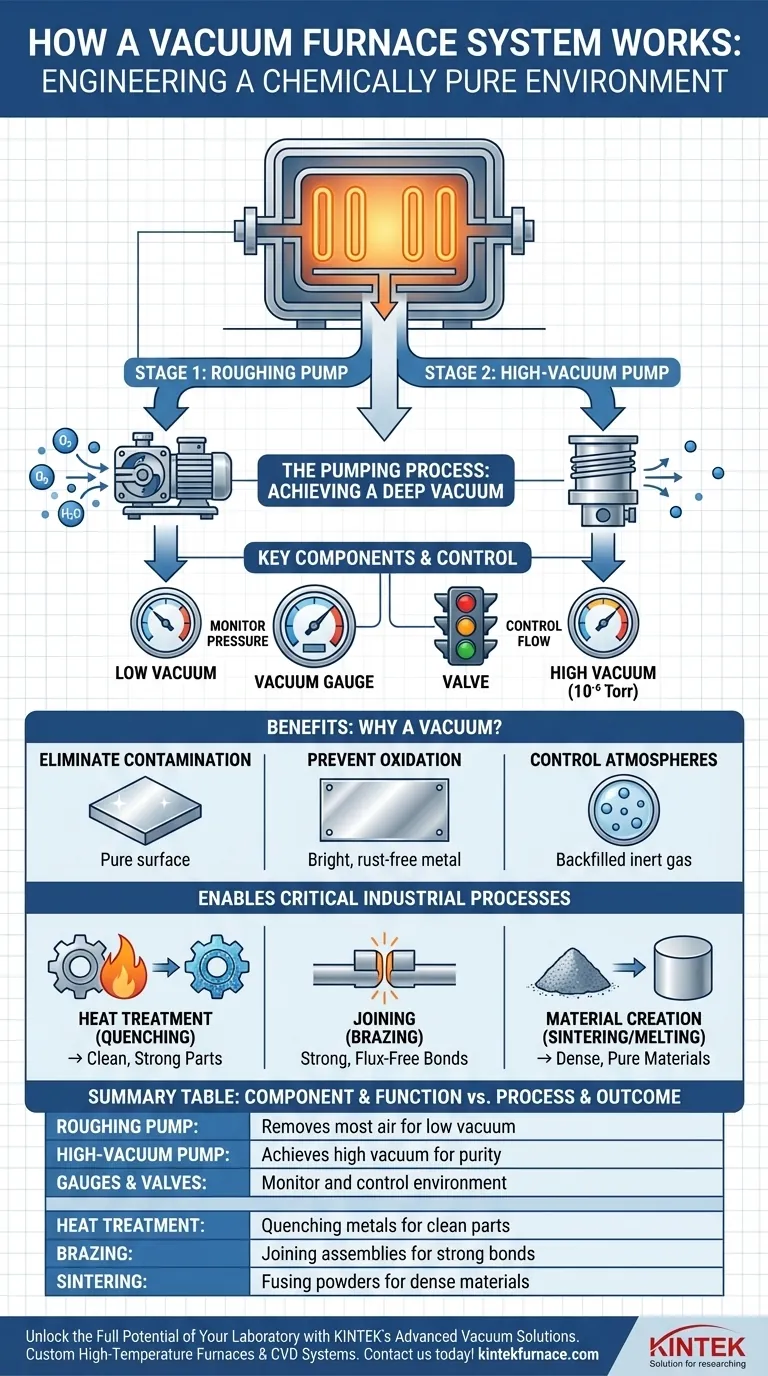

The Fundamental Goal: A Chemically Pure Environment

A vacuum furnace's primary advantage is its ability to control the atmosphere, or lack thereof, around a workpiece. This control is critical for achieving specific material properties that are impossible in a standard furnace.

Eliminating Contamination

When materials are heated to extreme temperatures, their surfaces become highly reactive. Any atmospheric gases present, such as oxygen or water vapor, will readily react with the material. The vacuum system removes these contaminants, ensuring the final product is pure and free from unwanted surface layers or chemical changes.

Preventing Oxidation

The most common and detrimental reaction at high temperatures is oxidation (rusting). By evacuating the chamber to a near-perfect vacuum, the system starves the environment of the oxygen needed for this process to occur. This results in bright, clean, oxidation-free parts.

Deconstructing the Pumping Process

Achieving a deep vacuum is typically a two-stage process, as no single pump is efficient across the entire pressure range from atmospheric pressure down to near-nothing.

Stage 1: The Roughing Pump

The process begins with a mechanical pump, often called a "roughing" pump. Its job is to do the heavy lifting, removing the vast majority of air from the chamber. This pump efficiently brings the chamber from atmospheric pressure down to a "soft" or "low" vacuum level.

Stage 2: The High-Vacuum Pump

Once the roughing pump has done its work, a high-vacuum pump takes over. This can be a diffusion pump or a turbomolecular pump, which operate on different principles but share the same goal. They are specialized for removing the remaining, sparsely distributed gas molecules to achieve the "high" or "hard" vacuum required for sensitive processes, reaching pressures as low as 10⁻⁶ Torr or even lower.

The Role of Gauges and Valves

This entire process is managed by a sophisticated control system. Vacuum gauges act as the speedometer, constantly measuring the pressure inside the chamber. Valves act as the traffic signals, opening and closing to isolate different pumps, control the pumpdown rate, or introduce specific inert gases like argon for partial pressure applications.

Understanding the Trade-offs and Considerations

While powerful, vacuum systems introduce complexities and require careful selection based on the specific industrial goal.

System Complexity and Cost

A vacuum furnace is inherently more complex and expensive than an atmospheric furnace. The need for robust sealed chambers, multiple pump types, and precise control systems adds significant cost and maintenance requirements.

Matching the Pump to the Process

Not all applications require an ultra-high vacuum. A process that only needs to prevent heavy oxidation might be successful with a simple mechanical pump system (a "soft" vacuum). However, applications requiring extreme purity, like vacuum brazing of aerospace components, demand a two-stage system to achieve a "high" vacuum.

Introducing Specific Atmospheres

Sometimes, a pure vacuum is not the final goal. The system can be used to first evacuate all contaminants and then backfill the chamber with a specific, high-purity inert gas. This creates a controlled, non-reactive atmosphere for processes like vacuum sintering, where the gas can aid in heat transfer without causing contamination.

How a Vacuum Enables Key Industrial Processes

The controlled environment created by the vacuum system is the key enabler for several critical manufacturing techniques.

For Heat Treatment (Quenching)

Heating and rapidly cooling metals in a vacuum (quenching) achieves desired hardness and strength without the scale and discoloration that occurs in air. The result is a cleaner, superior part that often requires no post-process cleaning.

For Joining (Brazing)

Vacuum brazing allows for the joining of complex assemblies. The filler metal melts and flows in a clean environment, creating a bond that is exceptionally strong and free from voids or flux contamination.

For Material Creation (Sintering & Arc Melting)

Processes like vacuum sintering fuse metal powders into solid objects, while vacuum arc melting purifies metals by melting them with an electric arc. In both cases, the vacuum ensures the final material is dense, pure, and possesses the desired structural integrity.

Choosing the Right Approach for Your Application

The configuration of a vacuum system is dictated entirely by the desired outcome of the process.

- If your primary focus is preventing basic oxidation: A simpler, single-pump system creating a "soft" vacuum is often sufficient and more cost-effective.

- If your primary focus is maximum purity and bond strength: A multi-stage system with high-vacuum pumps is non-negotiable to remove trace contaminants.

- If your primary focus is controlled chemical reactions: The system must be capable of both deep evacuation and precise backfilling with a specific process gas.

Ultimately, the vacuum system gives you absolute control over the chemical environment at high temperatures, empowering you to create materials and parts with unparalleled purity and performance.

Summary Table:

| Component | Function | Key Benefit |

|---|---|---|

| Roughing Pump | Removes most air for low vacuum | Cost-effective for basic oxidation prevention |

| High-Vacuum Pump | Achieves high vacuum for purity | Enables contamination-free processes |

| Gauges and Valves | Monitor and control vacuum environment | Ensures precise pressure management |

| Process | Application | Outcome |

| Heat Treatment | Quenching metals | Clean, strong parts without scale |

| Brazing | Joining assemblies | Strong, flux-free bonds |

| Sintering | Fusing metal powders | Dense, pure materials |

Unlock the Full Potential of Your Laboratory with KINTEK's Advanced Vacuum Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your experimental requirements.

Whether you're focused on preventing oxidation, achieving maximum purity, or enabling controlled chemical reactions, our vacuum systems deliver unparalleled performance and reliability. Don't let contamination hold back your research—contact us today to discuss how we can optimize your processes and drive innovation in your lab!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing