When choosing a vacuum press for metalworking, the key factors are the machine's capacity and size, its ability to handle the required temperature and pressure for your specific materials, and the precision of its control systems. These technical capabilities must then be weighed against your budget, maintenance considerations, and plans for future production.

The goal is not simply to buy a vacuum press, but to make a strategic investment. The right machine is one whose core capabilities—pressure, temperature, size, and control—are precisely aligned with the complexity of the parts you need to produce and the materials you intend to use.

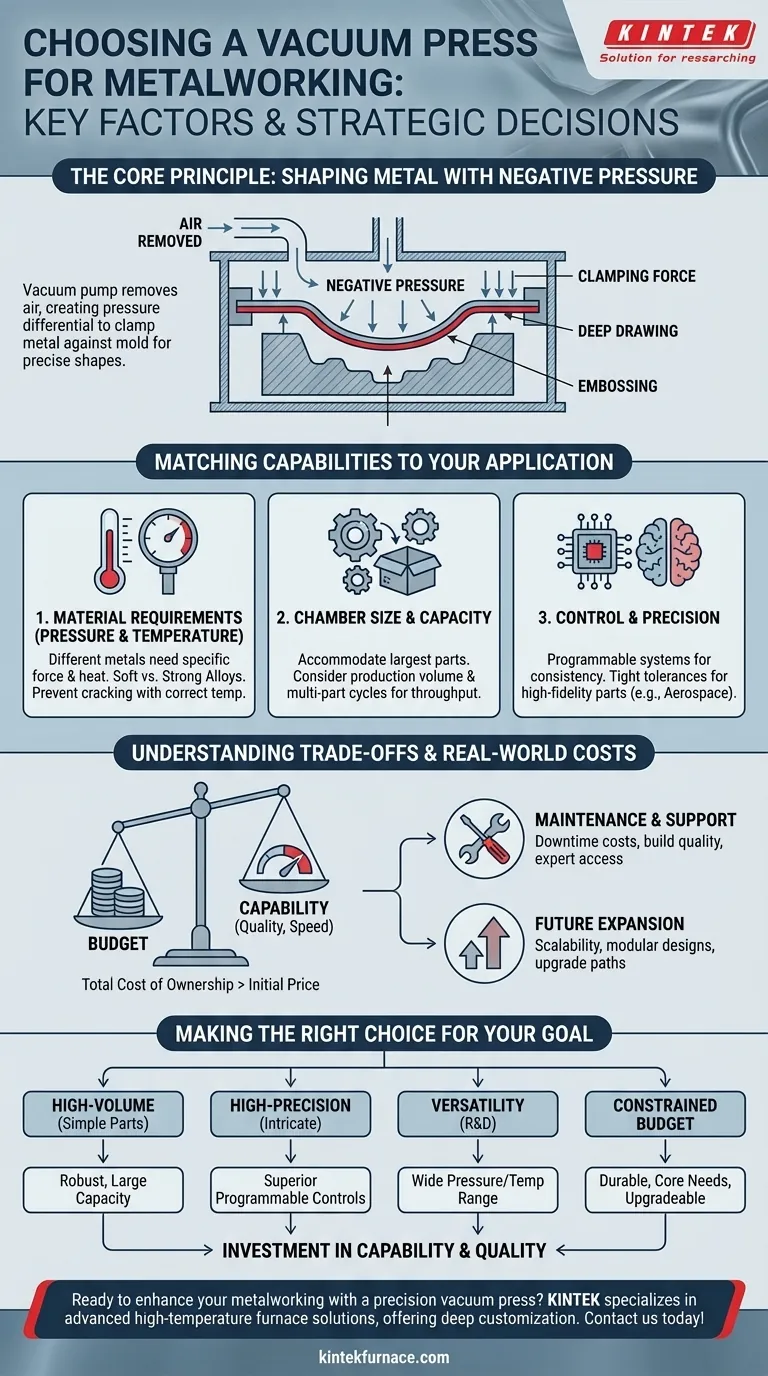

The Core Principle: How a Vacuum Press Shapes Metal

Understanding Negative Pressure

A vacuum press operates on a simple yet powerful principle. It uses a vacuum pump to remove the air from a sealed chamber, creating a significant difference in pressure between the inside and outside of the chamber.

This negative pressure acts as a powerful clamping force, drawing a sheet of metal tightly against a mold placed within the chamber. This process allows for the creation of precise shapes and complex curves without the need for a matching male and female die set used in traditional stamping.

Common Metalworking Applications

This technology is indispensable for tasks like deep drawing, where a metal sheet is stretched into a deep form, and embossing, where fine details are pressed into the surface. Industries from aerospace and automotive to jewelry manufacturing rely on vacuum presses to produce intricate, high-quality components efficiently.

Matching Machine Capabilities to Your Application

The most common mistake is focusing on one feature, like price or size, in isolation. A successful selection requires a holistic view of how the machine's specifications serve your manufacturing goals.

Factor 1: Material Requirements (Pressure & Temperature)

Different metals have vastly different forming characteristics. Softer metals like aluminum may require less pressure, while stronger alloys demand significantly more force to shape accurately.

Some advanced forming processes also require elevated temperatures to increase the metal's ductility and prevent cracking. Your press must be able to generate and sustain the specific pressure and temperature your materials demand.

Factor 2: Chamber Size and Capacity

The press chamber must be large enough to accommodate your largest mold and material blank. However, capacity isn't just about single-part dimensions.

Consider your production volume. A larger chamber may allow you to form multiple smaller parts in a single cycle, dramatically increasing throughput. It's crucial to balance current needs with potential future requirements for larger parts or higher volumes.

Factor 3: Control and Precision

For applications requiring high fidelity and repeatability, such as aerospace components, the level of control is paramount. Basic presses may have simple on/off vacuum controls.

Advanced systems offer programmable control over the rate of vacuum application and temperature ramping. This precision is what allows for the consistent production of complex parts with tight tolerances, minimizing defects and material waste.

Understanding the Trade-offs and Real-World Costs

A vacuum press is a long-term capital asset. The initial purchase price is only one part of its total cost of ownership.

The Budget vs. Capability Dilemma

The least expensive machine is rarely the most cost-effective. A press that cannot achieve the required pressure or control for your parts will lead to high scrap rates and production delays, quickly eroding any initial savings.

Frame your budget as an investment in capability. Prioritize the technical specifications that are non-negotiable for your product quality, and be wary of sacrificing them for a lower upfront cost.

Maintenance, Durability, and Support

Downtime is a direct cost to your operation. Assess the build quality, the reputation of the components (like the vacuum pump), and the ease of maintenance.

Furthermore, evaluate the manufacturer's or vendor's support. When a problem occurs, having access to expert technical support and readily available spare parts can be the difference between a minor delay and a catastrophic shutdown.

Thinking About Future Expansion

The press you buy today should not limit your business tomorrow. If you anticipate moving into more complex products or new materials, investing in a machine with capabilities beyond your immediate needs can be a wise decision.

Consider modular designs or manufacturers that offer clear upgrade paths for control systems or heating elements. This foresight prevents you from having to purchase an entirely new machine in just a few years.

Making the Right Choice for Your Goal

To select the right vacuum press, start by defining your primary objective.

- If your primary focus is high-volume production of simple parts: Prioritize a robust machine with a large chamber capacity and proven reliability over advanced control features.

- If your primary focus is intricate, high-precision components: Invest in a press with superior programmable controls for pressure and temperature, as this will define your product quality and repeatability.

- If your primary focus is versatility for R&D or varied projects: Look for a machine that offers a wide operational range of pressure and temperature, even if it has a smaller chamber.

- If you are working with a constrained budget: Concentrate on a durable, well-built machine that meets your core needs perfectly, and inquire about future upgrade possibilities.

Ultimately, choosing the right vacuum press is an investment in your production capability and quality.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material Requirements | Pressure and temperature needed for metals like aluminum or alloys to prevent cracking and ensure ductility. |

| Chamber Size and Capacity | Must fit largest mold and material blank; consider production volume for multiple parts per cycle. |

| Control and Precision | Programmable controls for vacuum rate and temperature ramping to achieve high repeatability and tight tolerances. |

| Budget and Costs | Total cost of ownership, including maintenance, downtime, and support to avoid high scrap rates and delays. |

| Future Expansion | Modular designs or upgrade paths for handling new materials or increased complexity in production. |

Ready to enhance your metalworking with a precision vacuum press? KINTEK specializes in advanced high-temperature furnace solutions, including vacuum and atmosphere furnaces, tailored for diverse laboratory needs. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique requirements for pressure, temperature, and control. Contact us today to discuss how our expertise can boost your production efficiency and quality!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- Why is a Vacuum Hot Press (VHP) furnace preferred over stir casting? Achieve Near-Theoretical Density for Composites

- What is the role of HIP equipment in the diffusion bonding of 6061 aluminum alloy? Achieve High-Integrity Metallurgy

- Why is isostatic graphite the most common material for SPS molds? Unlock High-Performance Sintering Precision

- How does graphite felt function as an insulation material in FAST equipment? Boost Efficiency & Thermal Uniformity

- Why is a hot pressing furnace equipped with a vacuum system necessary for sintering high-entropy alloy coatings? Ensure Purity, Density, and Superior Performance

- What are the advantages of benchtop SPS/FAST for titanium R&D? Accelerate Your Microstructural Engineering

- What processes are used for vacuum pressing and preforming of fabrics and fiber materials? Master Uniform Consolidation for Composites

- What are the features of a hot press sintering furnace? Achieve High-Density Materials with Precision Control