At its core, hot pressing is a high-performance manufacturing technique that simultaneously applies high temperature and immense pressure to a material. This combination forces the material's particles to fuse together, creating a final product that is exceptionally dense and strong. It is primarily used for advanced materials like ceramics and composites where internal defects must be minimized.

The true value of hot pressing lies in its ability to achieve near-theoretical density and superior mechanical properties. It accomplishes this by applying pressure during the heating and sintering phase, a result that heat alone cannot produce.

How Hot Pressing Fundamentally Works

To understand why hot pressing is chosen for critical applications, it's essential to look at the synergy between its two main components: heat and pressure.

The Core Principle: Simultaneous Application

Traditional sintering uses heat to bond material particles together, but this can leave behind small voids or pores. Hot pressing solves this by adding mechanical pressure at the same time. The heat makes the material pliable, while the pressure physically forces the particles together, eliminating空隙.

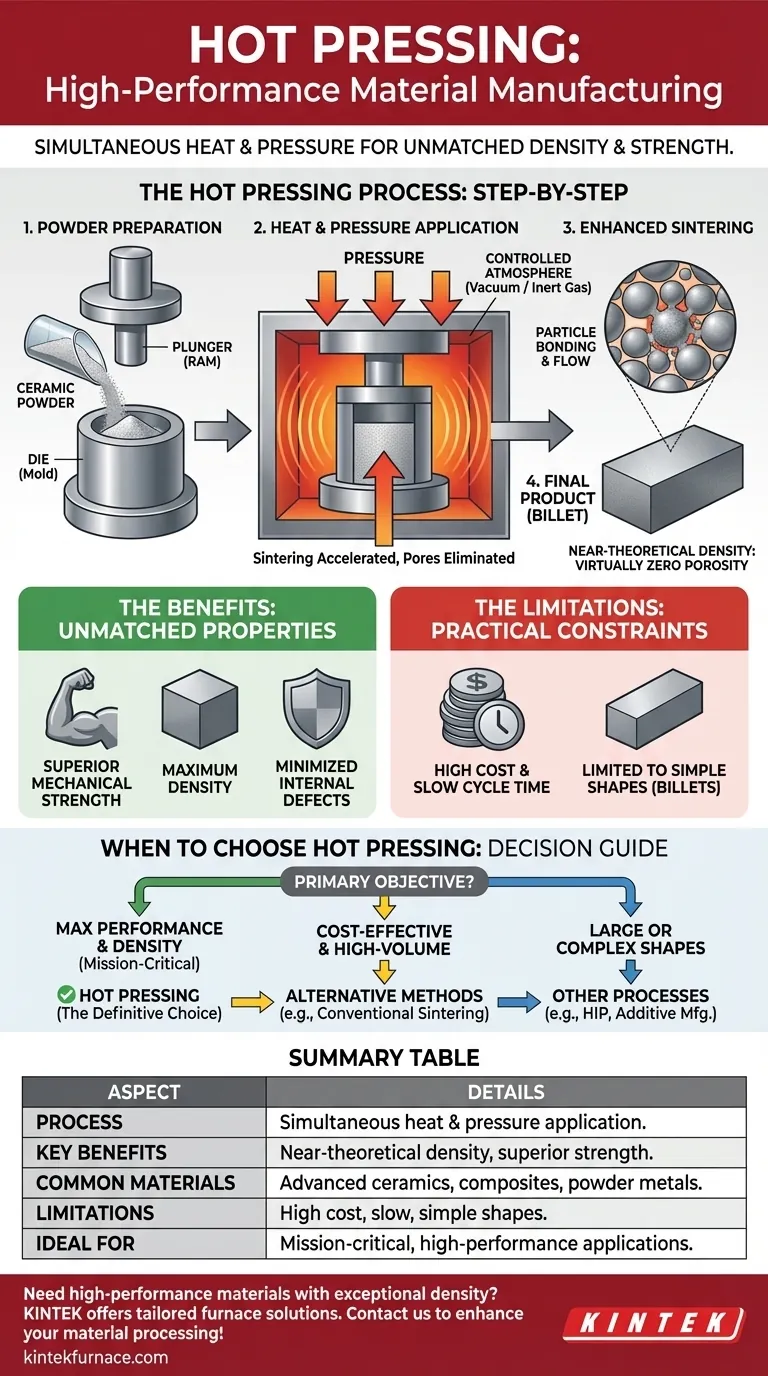

The Process Step-by-Step

The process begins by placing a powdered form of the material into a sturdy mold, typically made of graphite or a ceramic composite, called a die. A plunger, or ram, is then used to apply pressure. The entire assembly is heated in a controlled environment, often a vacuum or an inert gas atmosphere, to prevent oxidation at high temperatures.

The Role of Enhanced Sintering

As the temperature rises, the material particles begin to bond, a process known as sintering. The applied pressure dramatically accelerates this process and makes it more effective. It helps break down any surface contaminants on the powder particles and facilitates material flow, closing the pores that would otherwise become trapped.

Achieving Near-Theoretical Density

The ultimate goal is to achieve a density as close to the material's theoretical maximum as possible. This means creating a solid part with virtually zero internal porosity. The dense, void-free microstructure Ergebnisse from hot pressing leads directly to superior mechanical strength, hardness, and thermal and electrical properties. The final product is often a simple shape, like a disc or block, called a billet, which is then machined to its final dimensions.

Understanding the Trade-offs

Hot pressing is a powerful tool, but it is not a universal solution. Its benefits are balanced by significant practical limitations.

The Benefit: Unmatched Material Properties

For applications where performance is non-negotiable, hot pressing is often the only option. It produces materials with the highest possible density and mechanical strength, minimizing the risk of failure originating from internal pores or defects.

The Limitation: Cost and Cycle Time

Hot pressing equipment is specialized and expensive. The process is also relatively slow, as it involves heating and cooling the large die assembly. This makes it unsuitable for high-volume, low-cost manufacturing.

The Limitation: Shape and Size Constraints

The final part's geometry is limited by the shape of the die. Creating complex shapes is difficult and costly, and the overall size is constrained by the press's capacity. This is why it is often used to produce simple billets for subsequent machining.

When to Choose Hot pressing

Your choice to use hot pressing depends entirely on your project's primary objective.

- If your primary focus is maximum performance and density: Hot pressing is the superior method for creating mission-critical components from advanced ceramics, composites, or powder metals where porosity is a failure point.

- If your primary focus is cost-effective, high-volume production: Alternative methods like conventional sintering, die-casting, or metal injection molding are far more economical and faster.

- If your primary focus is creating large or geometrically complex parts: You should investigate other processes, such as hot isostatic pressing (HIP) or additive manufacturing, which offer greater design freedom.

Ultimately, hot pressing is the definitive choice when material integrity and performance cannot be compromised.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Simultaneous application of heat and pressure to fuse material particles |

| Key Benefits | Achieves near-theoretical density, superior mechanical strength, and minimal porosity |

| Common Materials | Advanced ceramics, composites, powder metals |

| Limitations | High cost, slow cycle time, limited to simple shapes and sizes |

| Ideal For | Mission-critical applications where performance and density are paramount |

Need high-performance materials with exceptional density and strength? At KINTEK, we leverage our advanced R&D and in-house manufacturing to provide tailored high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and more. Our deep customization capabilities ensure your unique experimental requirements are met precisely. Contact us today to discuss how our expertise can enhance your material processing and achieve superior results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- How do hot press furnaces contribute to graphene synthesis? Unlock High-Quality Material Production

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing