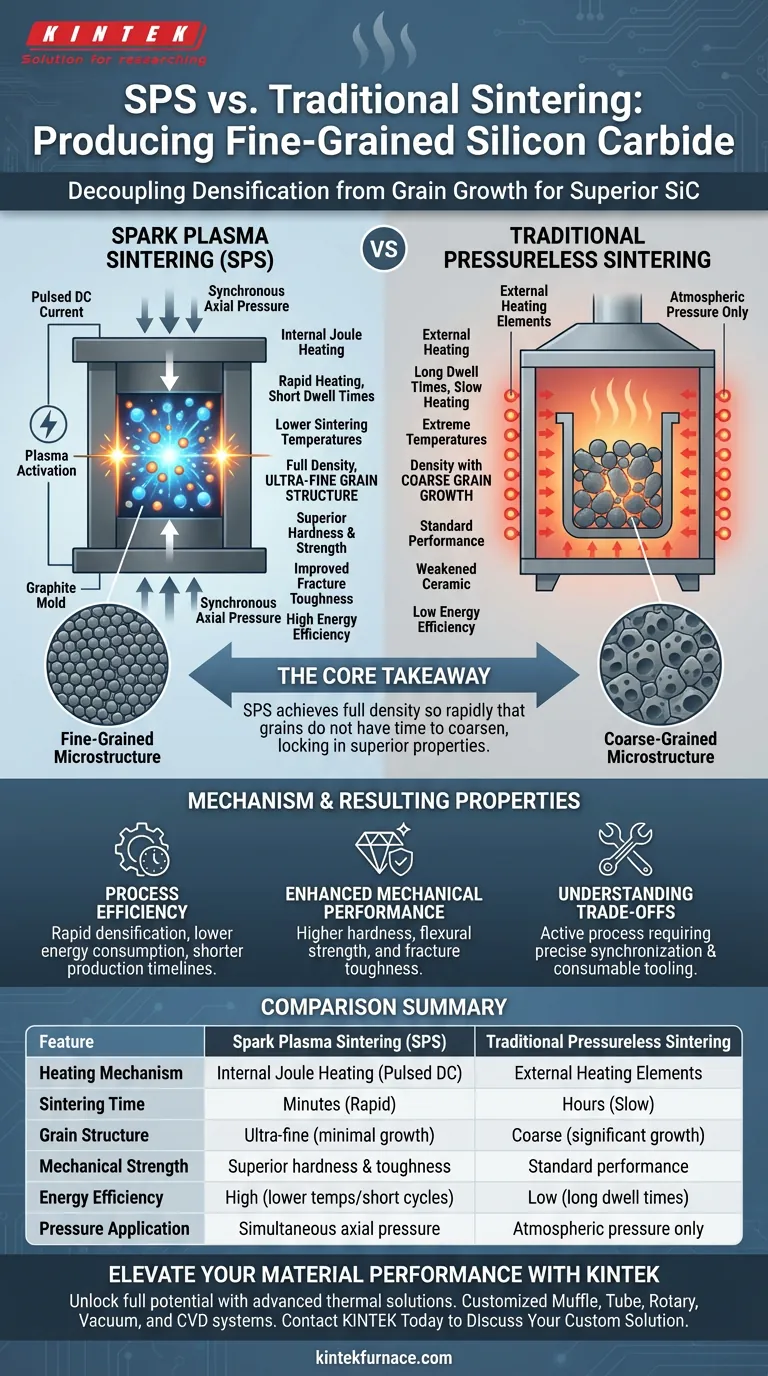

Industrial-grade Spark Plasma Sintering (SPS) offers a definitive advantage over traditional methods by decoupling densification from grain growth. utilizing field-assisted technology, SPS applies pulsed current and synchronous pressure to sinter Silicon Carbide (SiC) rapidly. This results in a fully dense material with an ultra-fine grain structure, superior mechanical properties, and significantly reduced energy consumption compared to pressureless sintering furnaces.

The Core Takeaway The critical flaw in traditional sintering is that the long dwell times required for density also allow grains to grow large, weakening the ceramic. SPS solves this by achieving full density so rapidly that the grains do not have time to coarsen, locking in superior hardness and strength.

The Mechanism: How SPS Achieves Superior Structure

Rapid Heating and Short Dwell Times

Traditional tube furnaces rely on external heating elements, which heat the sample slowly from the outside in. In contrast, SPS utilizes pulsed direct current to generate Joule heat directly within the mold or the sample itself.

This internal heating mechanism achieves heating rates of several hundred degrees per minute. By drastically reducing the dwell time at high temperatures, SPS prevents the uncontrolled grain growth inevitable in slower processes.

The Role of Synchronous Pressure

SPS does not rely on heat alone; it applies axial pressure simultaneously with the pulsed current. This mechanical force physically drives the densification of the Silicon Carbide powder.

Because pressure aids in closing pores, the material can reach full density at significantly lower temperatures than those required by pressureless sintering.

Plasma Activation Effect

The application of pulsed current promotes grain boundary diffusion through a phenomenon often referred to as the plasma activation effect. This accelerates the bonding process between particles, further shortening the processing time required to achieve a solid ceramic body.

Resulting Mechanical Properties

Enhanced Hardness and Strength

The primary output of maintaining an ultra-fine grain structure is a substantial increase in mechanical performance. Industrial SPS systems produce Silicon Carbide with higher hardness and flexural strength compared to coarse-grained counterparts produced in conventional furnaces.

Improved Fracture Toughness

Beyond static strength, the fine-grained microstructure contributes to superior fracture toughness. This makes the ceramic more resistant to crack propagation, a critical factor for industrial components under stress.

Process Efficiency and Energy Dynamics

Lower Sintering Temperatures

Because the synchronous pressure assists in compaction, SPS achieves complete densification at lower overall bulk temperatures. This is a distinct advantage over pressureless sintering, which often requires extreme heat to force particle coalescence.

Reduced Energy Consumption

The combination of rapid heating rates, short holding times, and lower operating temperatures results in significantly lower energy consumption. This makes SPS a more energy-efficient alternative to the prolonged heating cycles of high-temperature resistance furnaces.

Understanding the Trade-offs

Process Complexity vs. Simplicity

While pressureless sintering is a passive process (heat and wait), SPS is an active, dynamic process. It requires the precise synchronization of current, pressure, and temperature.

Tooling Dependencies

Unlike a pressureless furnace where parts are simply placed inside, SPS requires the powder to be contained within a conductive mold (typically graphite) to facilitate the current and pressure application. This introduces a requirement for consumable tooling and specific mold designs that withstand high mechanical loads.

Making the Right Choice for Your Goal

While SPS offers superior material properties, aligning the technology with your specific production goals is essential.

- If your primary focus is Maximum Mechanical Performance: Choose SPS to guarantee the ultra-fine grain structure required for peak hardness, flexural strength, and fracture toughness.

- If your primary focus is Process Efficiency: Choose SPS to utilize rapid densification cycles that reduce energy consumption and shorten production timelines.

- If your primary focus is Low-Temperature Processing: Choose SPS to achieve full density at temperatures lower than those required by traditional resistance furnaces, minimizing thermal stress on the facility.

SPS transforms Silicon Carbide production by substituting time and temperature with energy and pressure, yielding a stronger material in a fraction of the time.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Pressureless Sintering |

|---|---|---|

| Heating Mechanism | Internal Joule heating (Pulsed DC) | External heating elements |

| Sintering Time | Minutes (Rapid) | Hours (Slow) |

| Grain Structure | Ultra-fine (minimal growth) | Coarse (significant growth) |

| Mechanical Strength | Superior hardness & toughness | Standard performance |

| Energy Efficiency | High (lower temps/short cycles) | Low (long dwell times) |

| Pressure Application | Simultaneous axial pressure | Atmospheric pressure only |

Elevate Your Material Performance with KINTEK

Unlock the full potential of your Silicon Carbide production with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of high-temperature laboratory equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to meet your unique sintering requirements.

Whether you are aiming for peak mechanical hardness or energy-efficient processing, our experts are ready to help you design the perfect system for your lab or industrial facility.

Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

References

- Jie Long, Орест Кочан. Preparation of Oily Sludge-Derived Activated Carbon and Its Adsorption Performance for Tetracycline Hydrochloride. DOI: 10.3390/molecules29040769

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What types of heating elements are used in vacuum hot press furnaces? Optimize for High-Temp Performance

- What advantages does vacuum press technology offer in metal shaping processes? Achieve Precision and Efficiency in Metal Forming

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What is the key principle of a hot press sintering furnace? Achieve Superior Densification for High-Performance Materials

- What role does a vacuum hot pressing furnace play in (Ti2AlC + Al2O3)p/TiAl fabrication? Achieve 100% Densification

- What critical environmental conditions does a vacuum hot press furnace provide? Optimizing Copper-MoS2-Mo Composites

- What control features does a vacuum hot press furnace offer? Precision Control for Advanced Materials Processing

- How does Vacuum Hot Pressing (VHP) compare to CVD for ZnS ceramics? Unlock Superior Strength and Efficiency