At its core, a vacuum hot press furnace is an instrument of precision. It provides comprehensive, programmable control over the three most critical parameters in advanced materials processing: temperature, pressure, and the atmospheric environment. These systems are designed to execute complex, multi-stage recipes with high repeatability, ensuring consistent and predictable results for materials like ceramics, metals, and composites.

The true value of a vacuum hot press lies not just in its ability to get hot and press hard, but in its integrated control system. This system acts as a central brain, automating the entire process from start to finish, which is essential for both cutting-edge research and high-quality production.

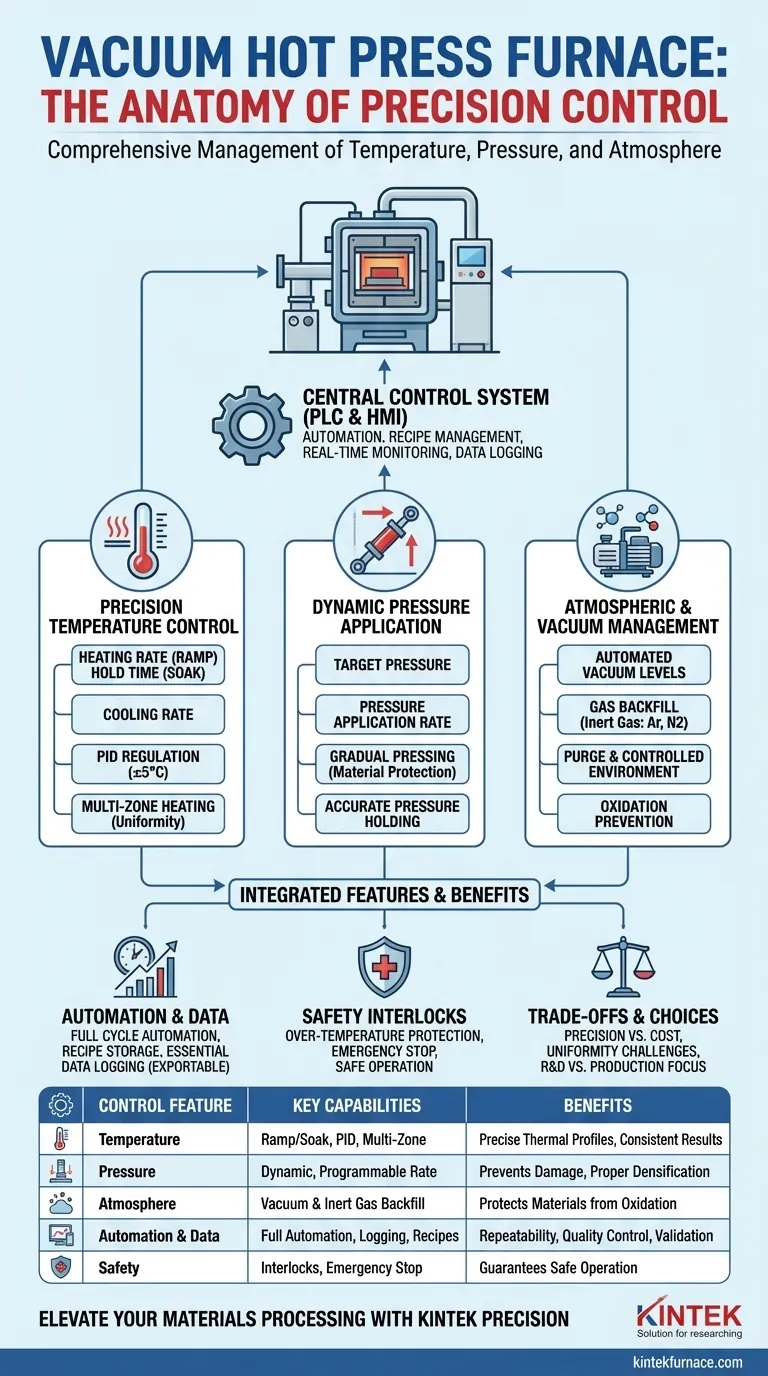

The Anatomy of Control: From System to Parameter

Modern vacuum hot press furnaces are managed by a centralized control system that coordinates the function of all other components. This integration is what enables their precision.

The Central Control System (PLC & HMI)

The heart of the furnace is a Programmable Logic Controller (PLC). This industrial computer is responsible for executing your pre-programmed instructions with high reliability.

The operator interacts with the PLC through a Human-Machine Interface (HMI), which is typically a color touch-panel display. This interface allows you to define every step of the process, save recipes, monitor progress in real-time, and access logged data.

Mastering the Key Process Variables

The control system gives you direct and programmable command over every essential physical variable. This allows you to create a unique "recipe" of heating, pressing, and atmospheric changes tailored to your specific material.

Precision Temperature Control

Controlling temperature involves more than just setting a single number. The system offers dynamic control over the entire thermal profile.

This includes setting the heating rate (ramp), holding a stable temperature for a set duration (soak), and controlling the cooling rate. Advanced systems use PID regulation and self-tuning technologies to maintain temperature stability often within ±5°C.

For greater uniformity, many furnaces feature multi-zone heating, allowing for independent temperature control in different sections of the furnace chamber.

Dynamic Pressure Application

The pressure system, typically hydraulic, is fully integrated into the control program. You can define not only the final target pressure but also the rate of pressure application.

This allows for gradual pressing, which is critical for preventing damage to brittle materials or ensuring complete densification of powders. The system will maintain the set pressure for the programmed duration with high accuracy.

Atmospheric and Vacuum Management

The furnace's atmosphere is a tightly controlled variable. The control system automates the vacuum system, allowing you to program specific vacuum levels (pump downs) to be reached and held.

It also manages the gas backfill system. This feature allows you to purge the vacuum and introduce a precise, inert gas like argon or nitrogen, creating a specific processing atmosphere that prevents oxidation and unwanted chemical reactions.

Automation, Data, and Safety

Beyond direct parameter control, the system provides features essential for process validation, repeatability, and safe operation.

Programmable Process Automation

A key feature is the ability to automate an entire cycle. An operator can program a complete recipe—including pump down, gas purge, heat ramp, soak, pressure application, cooling, and venting—and have the PLC execute it automatically from start to finish.

Essential Data Logging

For quality control and research, the system logs all critical process variables over time. This data, including temperature, pressure, and vacuum levels, can be exported for analysis, providing a definitive record of the process conditions for certification or process replication.

Integrated Safety Interlocks

Safety is paramount. The control system includes built-in safety features like over-temperature protection, which automatically shuts down the heating elements if a set limit is exceeded. It also includes interlocks and a prominent emergency stop function to ensure safe operation.

Understanding the Trade-offs

While powerful, these control systems come with inherent complexities and limitations that are important to understand.

Control Precision vs. System Cost

Greater precision comes at a price. A system with multi-zone heating, more sensitive sensors, faster data logging, and a more advanced PLC will be significantly more expensive than a basic model.

Uniformity Challenges

Despite advanced controls, achieving perfect temperature and pressure uniformity across a very large or complex-shaped part is a significant engineering challenge. The design of the furnace (e.g., cold-wall vs. hot-wall), heating element placement, and proper part loading are just as important as the control software.

The Human Element

A sophisticated control system is a tool, not a replacement for expertise. A knowledgeable operator is still required to develop a valid processing recipe, correctly interpret sensor data, and diagnose potential issues. The quality of the output is ultimately a partnership between the operator and the machine.

Making the Right Choice for Your Goal

The ideal set of control features depends entirely on your application.

- If your primary focus is research and development (R&D): Prioritize systems with flexible programming, advanced multi-zone temperature control, and comprehensive data logging to experiment with novel process cycles.

- If your primary focus is high-volume production: Emphasize robust automation for repeatable cycles, simplified operator interfaces for ease of use, and reliable safety interlocks to minimize errors and downtime.

- If your primary focus is processing highly sensitive materials: Look for superior vacuum performance (lower ultimate vacuum levels) and a precise gas flow control system to ensure absolute atmospheric purity.

Ultimately, the control features of a vacuum hot press transform it from a simple oven into a sophisticated instrument for materials engineering.

Summary Table:

| Control Feature | Key Capabilities | Benefits |

|---|---|---|

| Temperature Control | Programmable ramp, soak, cooling; PID regulation; multi-zone heating | Ensures precise thermal profiles and uniform heating for consistent results |

| Pressure Control | Dynamic application with programmable rates and target pressures | Prevents material damage and ensures proper densification |

| Atmosphere Control | Automated vacuum levels and inert gas backfill (e.g., argon, nitrogen) | Protects materials from oxidation and unwanted reactions |

| Automation & Data | Full process automation, recipe storage, real-time monitoring, data logging | Enhances repeatability, quality control, and process validation |

| Safety Features | Over-temperature protection, emergency stop, safety interlocks | Guarantees safe operation and minimizes risks |

Ready to elevate your materials processing with precision control?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, complemented by strong deep customization capabilities to meet your unique experimental requirements.

Whether you're in R&D, production, or handling sensitive materials, our vacuum hot press furnaces offer the programmable control, automation, and safety features you need for consistent, high-quality results.

Contact us today to discuss how we can customize a solution for your laboratory!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the overall benefits of using hot pressing in manufacturing? Achieve Superior Performance and Precision

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy