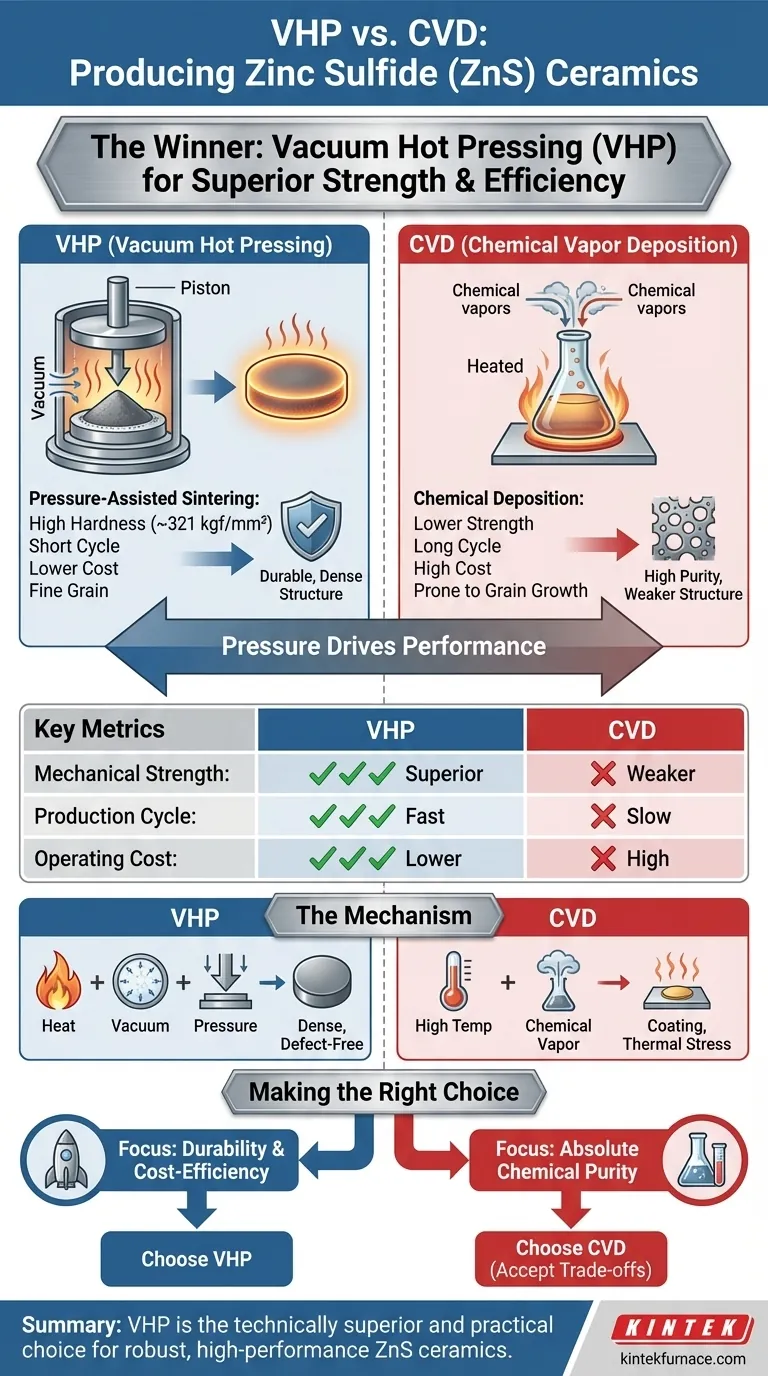

Vacuum Hot Pressing (VHP) significantly outperforms Chemical Vapor Deposition (CVD) when prioritizing mechanical strength and production efficiency for Zinc Sulfide (ZnS) ceramics.

While CVD is capable of producing high-purity material, it suffers from long production cycles, high costs, and results in mechanically weaker components. Conversely, VHP utilizes pressure-assisted sintering to produce ceramics with superior hardness and optimized microstructures, making them the standard for harsh environments like missile domes.

Core Takeaway For applications requiring structural durability and cost-effective manufacturing, VHP is the decisive winner over CVD. VHP overcomes the mechanical limitations of CVD by achieving near-theoretical density and higher hardness through a faster, pressure-driven process.

Mechanical Properties: Why VHP Yields Stronger Ceramics

Superior Hardness and Microstructure

VHP produces ZnS ceramics with significantly higher mechanical strength than those produced by CVD.

The process yields an optimized microstructure with elevated hardness values, such as 321 kgf/mm², which is critical for components that must withstand physical stress.

The Detriment of High CVD Temperatures

CVD processes often require extreme deposition temperatures ranging from 900°C to 2000°C.

These high temperatures can cause structural changes and deformation in the substrate material. This thermal stress frequently leads to a reduction in the overall mechanical properties of the body and weakens the bond between the coating and the substrate.

Grain Growth Suppression

VHP applies mechanical pressure (typically around 15–20 MPa) during heating.

This pressure allows for densification at lower temperatures, which suppresses excessive grain growth. Finer grain structures correlate directly to improved mechanical strength and toughness in the final ceramic.

Efficiency and Cost: The VHP Advantage

Reduced Production Cycle

The VHP process offers a significantly shorter production cycle compared to the slow deposition rates of CVD.

By simultaneously applying heat and pressure, VHP achieves densification much faster than the chemical growth process required by CVD.

Lower Equipment Costs

CVD involves complex, expensive equipment to manage volatile chemical precursors and high-temperature environments.

In contrast, VHP furnaces are generally simpler and lower in cost to operate. This makes VHP a more economically viable option for industrial-scale production of ZnS ceramics.

The Mechanism: How VHP Achieves Density

Simultaneous Vacuum, Heat, and Pressure

The success of VHP lies in the simultaneous application of high temperature (approx. 1020°C), high vacuum (10^-3 to 10^-5 mtorr), and mechanical pressure.

This combination creates a "pressure-assisted sintering" mechanism. It forces particle rearrangement and plastic flow that CVD simply cannot replicate.

Elimination of Defects

The high vacuum environment is essential for extracting volatile impurities and trapped gases from the powder interstices.

By forcibly removing these micro-pores, VHP creates a dense structure close to theoretical density. This not only improves strength but also ensures excellent infrared transmittance by minimizing light scattering.

Understanding the Trade-offs

Purity vs. Strength

While the primary reference notes that CVD produces high-purity ZnS, this purity comes at the cost of mechanical integrity.

If absolute chemical purity is the sole metric, CVD has merit; however, for any application involving physical stress or impact, the structural weakness of CVD is a major liability.

Thermal Constraints

CVD's high-temperature requirement restricts the choice of suitable substrate materials.

VHP operates at relatively lower temperatures (960°C–1040°C) due to the assistance of physical pressure, allowing for a wider range of processing options without deforming the component.

Making the Right Choice for Your Project

When selecting a manufacturing method for Zinc Sulfide ceramics, align your choice with your specific environmental requirements.

- If your primary focus is Durability and Impact Resistance: Choose Vacuum Hot Pressing (VHP) for its superior hardness and optimized microstructure, essential for missile domes and protective windows.

- If your primary focus is Cost and Speed: Choose Vacuum Hot Pressing (VHP) to leverage its shorter production cycles, lower equipment costs, and operational simplicity.

- If your primary focus is Absolute Chemical Purity: Acknowledge that CVD offers high purity, but be prepared to accept higher costs, longer lead times, and reduced mechanical strength.

Summary: For robust, high-performance ZnS ceramics delivered efficiently, Vacuum Hot Pressing is the technically superior and most practical manufacturing route.

Summary Table:

| Feature | Vacuum Hot Pressing (VHP) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Mechanical Strength | Superior (Hardness ~321 kgf/mm²) | Lower (Structural weakness) |

| Production Cycle | Short (Fast densification) | Long (Slow deposition rates) |

| Operating Cost | Lower (Simpler equipment) | High (Complex precursor management) |

| Microstructure | Fine grain; near-theoretical density | Prone to grain growth & thermal stress |

| Typical Use Case | Durable missile domes & windows | High-purity specialized coatings |

Optimize Your Ceramic Production with KINTEK

Are you looking to achieve maximum durability and cost-efficiency for your Zinc Sulfide (ZnS) components? Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Pressing systems, Muffle, Tube, Rotary, and CVD systems—all fully customizable to meet your unique lab and industrial needs.

Our advanced high-temperature furnaces empower you to produce near-theoretical density materials with superior mechanical integrity and faster turnaround times. Don't settle for less—partner with KINTEK to elevate your material science capabilities.

Contact Our Experts Today to Find Your Custom Solution

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is the synchronous axial pressure function of a Spark Plasma Sintering (SPS) furnace essential for MgTiO3-CaTiO3?

- What is hot pressing and what does it involve? Unlock Superior Material Density and Strength

- What are the primary advantages of industrial SPS vs. vacuum hot-pressing for Ti-6Al-4V? Achieve Superior Microstructure

- What functions does a graphite mold serve during ZnS vacuum hot pressing? Optimize Density and Optical Purity

- How does a hot pressing (HP) system achieve full densification? Achieve 100% Density in Ti-5Al-4W-2Fe Alloys

- What is the primary role of mechanical pressure in Ti-Al vacuum hot pressing? Optimize Bonding and Density

- What is the function of applying axial pressure during hot press sintering? Achieve High-Density Metal Composites

- How does vacuum hot press sintering compare to SPS for Fe-Cu composites? Achieve Superior Industrial Quality