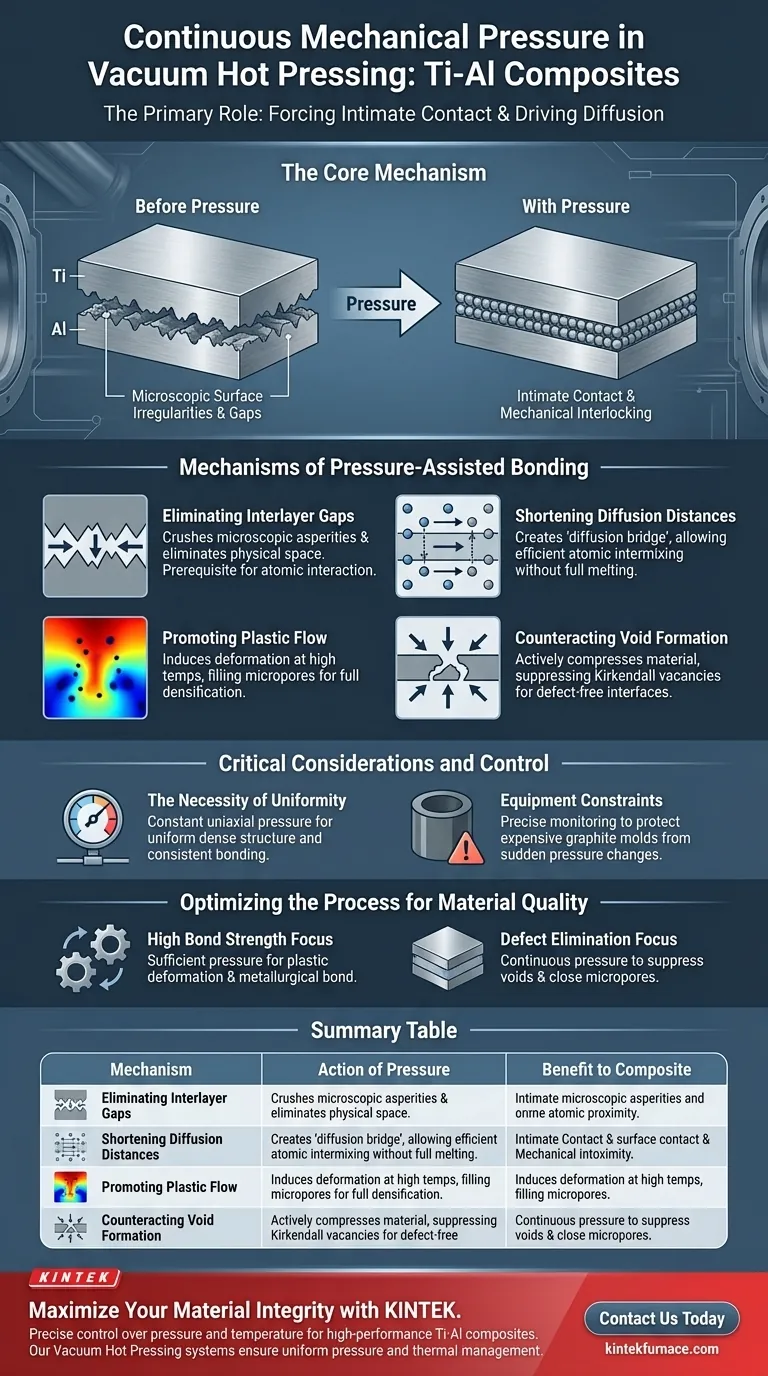

The primary role of continuous mechanical pressure during vacuum hot pressing is to force the stacked titanium and aluminum layers into intimate physical contact at the microscopic level. By physically compressing the layers, the pressure eliminates minute gaps and shortens the distance atoms must travel, providing the necessary driving force for mutual diffusion and solid-state bonding.

The Core Mechanism

Mere high temperature is often insufficient for bonding because microscopic surface irregularities create barriers between layers. Mechanical pressure overcomes this by mechanically interlocking the surfaces, ensuring the close atomic proximity required to transform separate metal foils into a single, cohesive composite.

Mechanisms of Pressure-Assisted Bonding

Eliminating Interlayer Gaps

Metal foils may appear flat to the naked eye, but at a microscopic level, they possess roughness and irregularities. Mechanical pressure forces these uneven surfaces together, crushing asperities and physically closing the tiny voids that naturally exist between stacked layers. This elimination of physical space is the prerequisite for any subsequent chemical or atomic interaction.

Shortening Diffusion Distances

Atomic diffusion—the movement of atoms from one material into another—is the fundamental engine of solid-state bonding. By forcing the layers into close contact, pressure drastically shortens the distance titanium and aluminum atoms must migrate to cross the interface. This proximity creates a "diffusion bridge," allowing atoms to intermix efficiently without requiring the materials to fully melt.

Promoting Plastic Deformation

At the high temperatures used in vacuum hot pressing (e.g., 1000°C), metal foils become softer and more malleable. The applied pressure induces plastic flow and rearrangement of the material, forcing the metal to flow into and fill any remaining micropores. This process is essential for achieving full densification, ensuring the final composite is solid and free of porosity.

Counteracting Void Formation

During the diffusion process, atoms may move at different rates, potentially creating vacancies known as Kirkendall voids. Continuous external pressure helps counteract the formation of these voids by actively compressing the material as diffusion occurs. This results in a defect-free interface layer, which is critical for the mechanical integrity of the composite.

Critical Considerations and Control

The Necessity of Uniformity

Applying pressure is not simply about force; it is about uniform distribution. The pressure control system must maintain a constant uniaxial pressure (e.g., 30 MPa) to ensure the composite structure is dense throughout, not just in specific spots. Uneven pressurization can lead to inconsistent bonding quality and structural weak points.

Equipment Constraints

While high pressure is beneficial for bonding, it must be balanced against equipment limitations. Sudden changes in pressure or excessive force can damage the graphite molds typically used in these furnaces. Precise monitoring is required to protect expensive tooling while maintaining the conditions necessary for densification.

Optimizing the Process for Material Quality

To achieve the best results in Ti-Al composite fabrication, align your pressure strategy with your specific defect-reduction goals:

- If your primary focus is High Bond Strength: Ensure the pressure is sufficient to induce plastic deformation, as this physical interlocking is the foundation of a robust metallurgical bond.

- If your primary focus is Defect Elimination: Maintain continuous, constant pressure throughout the hold time to suppress the formation of Kirkendall voids and close micropores.

By effectively managing mechanical pressure, you convert a stack of loose foils into a fully dense, high-performance composite structure.

Summary Table:

| Mechanism | Action of Pressure | Benefit to Composite |

|---|---|---|

| Gap Elimination | Crushes microscopic surface asperities | Ensures intimate physical contact |

| Atomic Diffusion | Shortens migration distance for Ti and Al | Accelerates solid-state bonding |

| Plastic Flow | Induces material deformation at high temp | Achieves full densification & zero porosity |

| Void Control | Compresses Kirkendall vacancies | Prevents interface defects & weak points |

Maximize Your Material Integrity with KINTEK

Precise control over pressure and temperature is non-negotiable for high-performance Ti-Al composites. KINTEK provides industry-leading Vacuum Hot Pressing systems, CVD units, and customizable high-temperature furnaces designed specifically for advanced metallurgy and R&D.

Backed by expert manufacturing, our equipment ensures uniform pressure distribution and precise thermal management to protect your graphite molds while achieving superior bond strength. Contact us today to discuss how our customizable lab solutions can enhance your composite fabrication process.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a vacuum environment important in hot pressing? Essential for Purity and High-Density Materials

- What are the advantages of using a Spark Plasma Sintering (SPS) system? Unlock High-Entropy Alloy Performance

- How does a vacuum hot press furnace facilitate the densification of Al-Si/graphite? Achieve 100% Thermal Density

- What role does uniaxial pressure play in a carbon tube vacuum hot press furnace? Achieve Ceramic Transparency

- Why is high-precision temperature control essential for the vacuum hot press furnace? Optimize Ti-Al3Ti Composites

- How does a vacuum hot press furnace benefit sintering experiments? Achieve Superior Material Density and Purity

- What is the function of a rigid mould in vacuum hot pressing? Master Structural Precision in Layered Composites

- What factors should be considered when choosing a vacuum press for metalworking? Optimize Your Investment for Precision and Efficiency