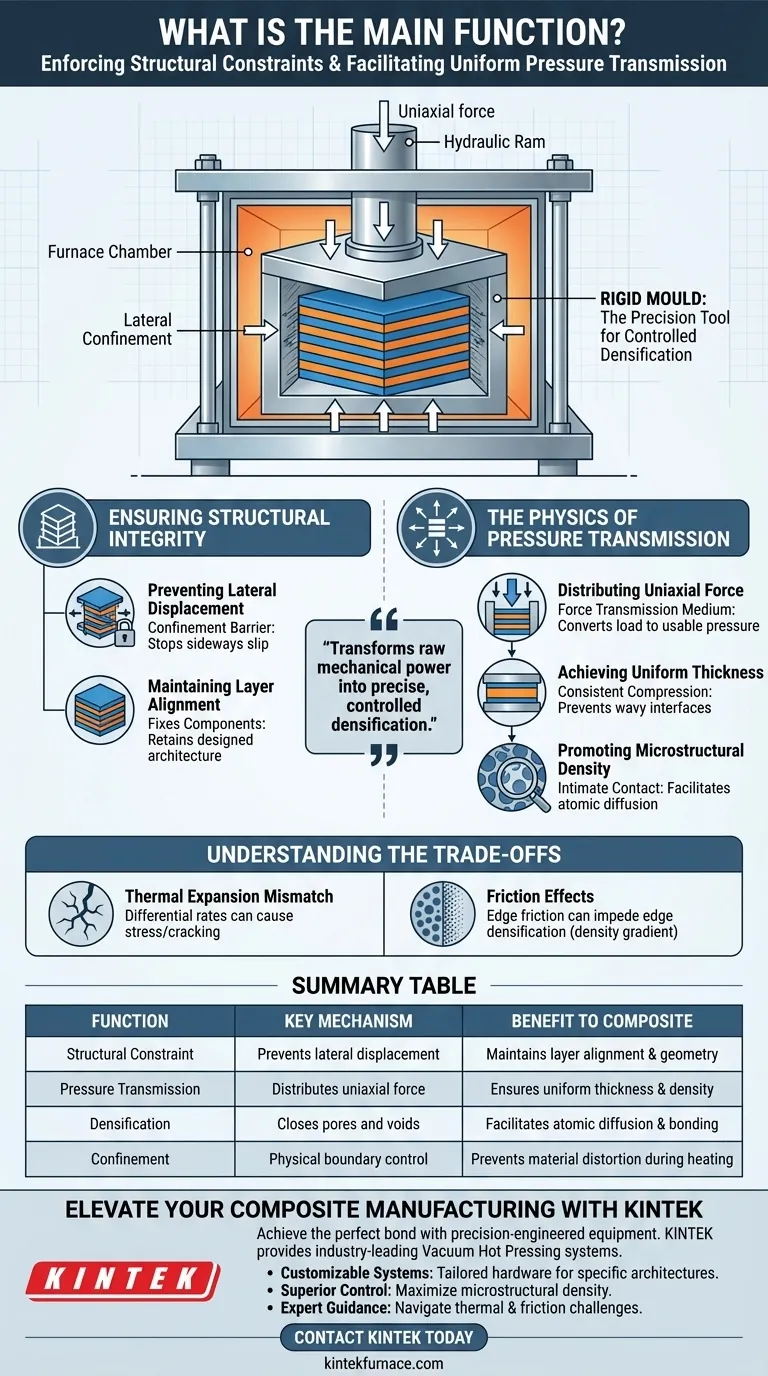

The main function of a rigid mould in vacuum hot pressing is to enforce structural constraints and facilitate uniform pressure transmission. It physically secures the alternating stack of materials—such as amorphous ribbons and aluminum foils—preventing them from sliding laterally or becoming misaligned during processing. Simultaneously, acts as the medium that transfers the furnace's uniaxial force to the sample, ensuring the layers compress into a dense, uniform microstructure.

The rigid mould transforms the furnace's raw mechanical power into precise, controlled densification. It creates a physical boundary that forces the composite layers to bond vertically rather than shifting horizontally.

Ensuring Structural Integrity

Preventing Lateral Displacement

When mechanical pressure is applied to a stack of distinct layers, the materials naturally tend to slip sideways. The rigid mould acts as a confinement barrier, locking the stack in place within the furnace chamber.

Maintaining Layer Alignment

For composites relying on alternating structures (e.g., metal foils and ribbons), precise alignment is critical. The mould fixes the position of these components, ensuring the final composite retains its designed architecture without distortion during the heating phase.

The Physics of Pressure Transmission

Distributing Uniaxial Force

The mould serves as the direct link between the hydraulic ram and the composite sample. It functions as a force transmission medium, converting the raw load from the machine into usable, targeted pressure on the material stack.

Achieving Uniform Thickness

By distributing this pressure evenly, the mould ensures the entire sample compresses at the same rate. This uniformity is essential for achieving consistent layer thickness across the entire composite, preventing wavy or uneven interfaces.

Promoting Microstructural Density

The constraint provided by the mould allows the pressure to effectively close pores and gaps. This facilitates the intimate contact required for atomic diffusion, resulting in a dense microstructure free of voids.

Understanding the Trade-offs

Thermal Expansion Mismatch

While the mould provides necessary constraint, it may expand or contract at a different rate than the composite materials. Significant mismatches in thermal expansion can lead to stress accumulation, potentially causing cracks in the composite or difficulty in removing the sample after sintering.

Friction Effects

Friction between the composite layers and the inner walls of the rigid mould can occasionally impede densification at the edges. This can create a "density gradient," where the center of the sample is more compressed than the outer perimeter.

Making the Right Choice for Your Goal

To maximize the quality of your layered composite, consider these factors when selecting or designing your mould:

- If your primary focus is geometric precision: Prioritize mould designs with tight tolerances to strictly limit any lateral movement or misalignment of the foil stack.

- If your primary focus is maximum density: Ensure the mould material has high compressive strength to withstand and transmit high uniaxial pressures without deforming.

A rigid mould is not just a container; it is the primary tool for translating mechanical energy into material quality.

Summary Table:

| Function | Key Mechanism | Benefit to Composite |

|---|---|---|

| Structural Constraint | Prevents lateral displacement | Maintains layer alignment & geometry |

| Pressure Transmission | Distributes uniaxial force | Ensures uniform thickness & density |

| Densification | Closes pores and voids | Facilitates atomic diffusion & bonding |

| Confinement | Physical boundary control | Prevents material distortion during heating |

Elevate Your Composite Manufacturing with KINTEK

Achieving the perfect bond in layered composites requires more than just heat—it requires precision-engineered equipment. KINTEK provides industry-leading Vacuum Hot Pressing systems, backed by expert R&D and manufacturing. Our solutions are designed to handle the critical pressure transmission and thermal constraints necessary for high-performance material synthesis.

Why choose KINTEK?

- Customizable Systems: From Muffle and Tube to specialized Vacuum and CVD furnaces, we tailor hardware to your specific layer architectures.

- Superior Control: Ensure maximum microstructural density with our high-strength furnace designs.

- Expert Guidance: Our team helps you navigate thermal expansion and friction challenges to deliver void-free results.

Ready to optimize your lab's high-temperature processing? Contact KINTEK today to discuss your unique needs!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of using a vacuum hot press? Achieve Superior Material Quality and Precision

- What are the advantages of using a vacuum hot pressing furnace? Superior 2024Al/Gr/SiC Composite Performance

- What is vacuum hot pressing (VHP) and what materials is it suitable for? Unlock High-Density Material Solutions

- What role does a vacuum hot press sintering furnace play in Ti/Al2O3 processing? Achieve 99% Density

- What functions do graphite molds serve in the vacuum hot pressing of copper-carbon nanotube composites?

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?

- What roles do graphite molds play during the SPS of MgTiO3-CaTiO3? Achieve Rapid Densification and Precision

- What are the advantages of SPS vs Hot Pressing for Ti-6Al-4V/HA? Maximize Bioactivity with Rapid Sintering