The vacuum hot press sintering furnace serves as the critical enabler for processing Ti/Al2O3 composites, acting as the only reliable method to consolidate these dissimilar materials into a high-performance structural component.

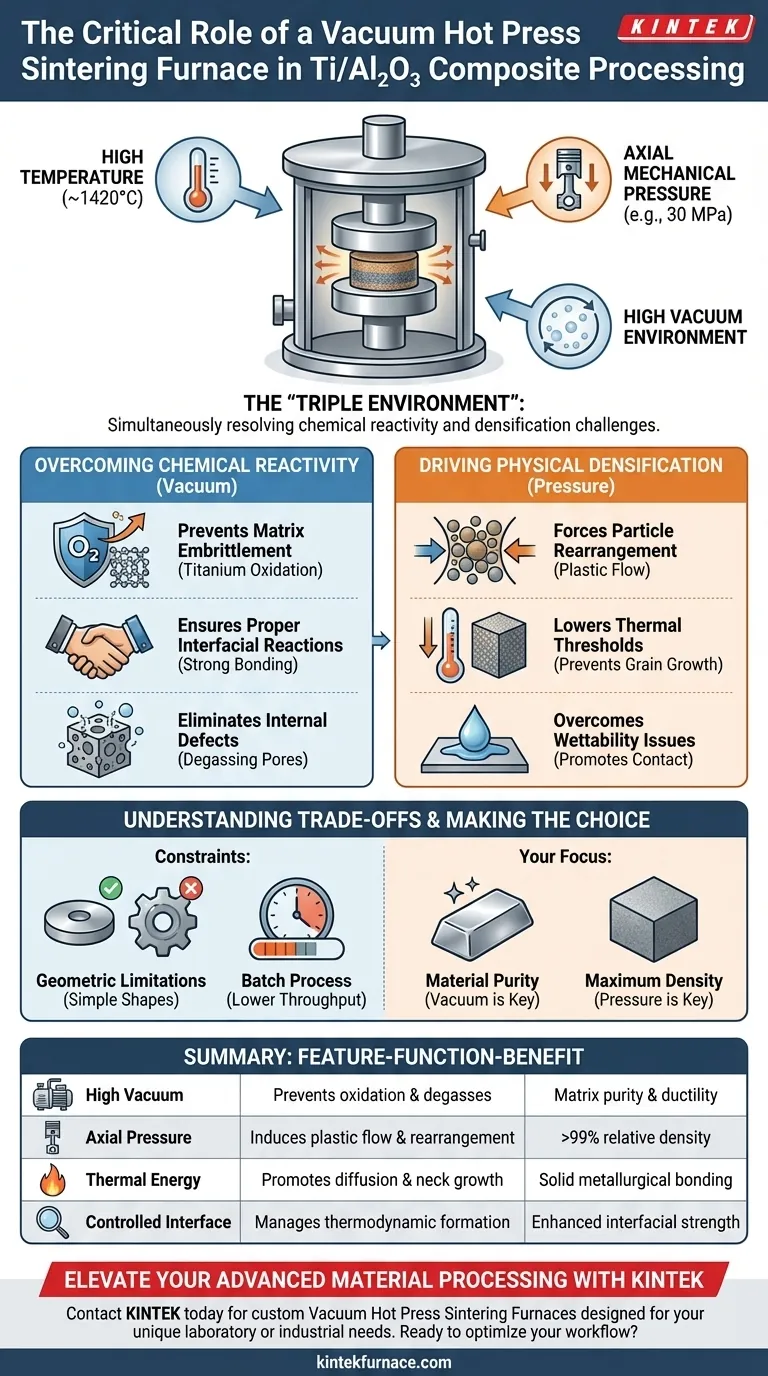

It achieves this by creating a simultaneous "triple environment" of high temperature (approx. 1420°C), axial mechanical pressure (e.g., 30 MPa), and high vacuum. This combination resolves the two fundamental conflicts in processing this composite: the extreme reactivity of titanium with oxygen and the inherent difficulty of densifying ceramic particles without melting the metal matrix.

Core Takeaway By applying mechanical pressure alongside thermal energy, this equipment forces particle rearrangement and plastic flow, significantly lowering the temperature required for densification. This allows for the production of composites with relative densities approaching 99% while the vacuum environment ensures the titanium matrix remains chemically pure and ductile.

Overcoming Chemical Reactivity

Titanium is notoriously difficult to process due to its high affinity for oxygen. The vacuum aspect of the furnace is not merely a feature; it is a strict necessity for material integrity.

Preventing Matrix Embrittlement

At the elevated temperatures required for sintering, metallic titanium becomes highly reactive. Without a high-vacuum environment, the titanium would severely oxidize.

This oxidation leads to the formation of brittle oxide layers rather than the desired metallic matrix. The vacuum reduces the oxygen partial pressure, preserving the ductility and purity of the titanium.

Ensuring Proper Interfacial Reactions

For a Ti/Al2O3 composite to function effectively, the interface between the metal and ceramic must be strong.

Vacuum conditions ensure that interface reactions proceed thermodynamically to form desired intermetallics (such as Ti3Al or TiAl) rather than impurity-filled oxide barriers that weaken the material.

Eliminating Internal Defects

The vacuum actively facilitates the removal of gases trapped in the interstitial spaces between powder particles.

By degassing the powder compact during the heating phase, the furnace reduces internal porosity defects, which is critical for enhancing the final mechanical properties and interface bonding quality.

Driving Physical Densification

Standard pressureless sintering relies solely on atomic diffusion, which often fails to fully densify composites containing hard ceramic particles like Al2O3. The "hot press" function solves this limitation.

Forcing Particle Rearrangement

The application of uniaxial pressure (e.g., 30 MPa) creates a driving force that thermal energy alone cannot provide.

This pressure physically forces the rearrangement of solid particles and induces plastic flow in the materials. This effectively fills voids and pores that would otherwise remain in the structure.

Lowering Thermal Thresholds

High pressure significantly lowers the activation energy required for densification.

This enables the composite to reach near-theoretical density (approx. 99%) at lower temperatures (e.g., 1420°C) than would be required in pressureless sintering. Lower temperatures help prevent excessive grain growth, preserving the material's mechanical strength.

Overcoming Wettability Issues

Ceramics often have poor wettability with metals.

The mechanical force helps overcome these surface tension issues, promoting contact between the titanium and alumina phases. This mechanical assistance drives atomic diffusion and neck growth, ensuring a solid metallurgical bond.

Understanding the Trade-offs

While vacuum hot pressing is superior for quality, it introduces specific constraints that you must plan for during production.

Geometric Limitations

The pressure is applied uniaxially (from top and bottom).

This limits the geometry of the final parts to relatively simple shapes, such as discs, plates, or cylinders. Complex 3D geometries with undercuts are generally not possible without extensive post-process machining.

Throughput vs. Quality

This is a batch process, not a continuous one.

The cycle times are longer due to the need to pull a vacuum, heat the mass, apply pressure, and cool down under controlled conditions. While the density is superior (approaching 99%), the production rate is significantly lower than conventional sintering methods.

Making the Right Choice for Your Goal

The vacuum hot press sintering furnace is a specialized tool designed for high-performance applications where material failure is not an option.

- If your primary focus is Material Purity: The high-vacuum capability is your most critical feature, as it prevents titanium oxidation and ensures a ductile, fracture-resistant matrix.

- If your primary focus is Maximum Density: The axial pressure system is the key driver, allowing you to achieve >98% relative density in composites that are otherwise difficult to sinter.

Ultimately, this furnace converts a chemically risky and mechanically difficult process into a controlled, repeatable method for creating high-density aerospace and structural composites.

Summary Table:

| Feature | Function in Ti/Al2O3 Processing | Primary Benefit |

|---|---|---|

| High Vacuum | Prevents titanium oxidation & degasses powder | Matrix purity and ductility |

| Axial Pressure | Induces plastic flow & particle rearrangement | >99% relative density |

| Thermal Energy | Promotes atomic diffusion & neck growth | Solid metallurgical bonding |

| Controlled Interface | Manages thermodynamic intermetallic formation | Enhanced interfacial strength |

Elevate Your Advanced Material Processing with KINTEK

Precision matters when handling reactive materials like Titanium and Alumina. KINTEK provides industry-leading Vacuum Hot Press Sintering Furnaces designed to deliver the simultaneous pressure, temperature, and vacuum integrity your composites require.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your unique laboratory or industrial needs. Whether you are aiming for near-theoretical density or high-purity metallurgical bonds, our technical team is ready to support your project.

Ready to optimize your sintering workflow? Contact KINTEK today for a custom solution!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the primary technical advantages of using a Spark Plasma Sintering (SPS) system? Achieve Superior Sintering

- Why are pressure and temperature control crucial for Cu-CNT composites? Eliminate Delamination in Vacuum Hot Pressing

- What role does the mechanical pressure applied by the hot pressing mechanism play? Optimize Densification Now

- What is hot press sintering and how is it used with metal and ceramic powders? Achieve Superior Density and Performance

- What role does a vacuum hot pressing furnace play in (Ti2AlC + Al2O3)p/TiAl fabrication? Achieve 100% Densification

- What is the use of a hot press? Achieve Perfect Bonding & High-Performance Materials

- What function does Spark Plasma Sintering (SPS) equipment serve in recycling aluminum alloy scrap? High-Value Recovery

- What are the benefits of the high vacuum environment in a vacuum hot pressing sintering furnace? Gain Maximum Density