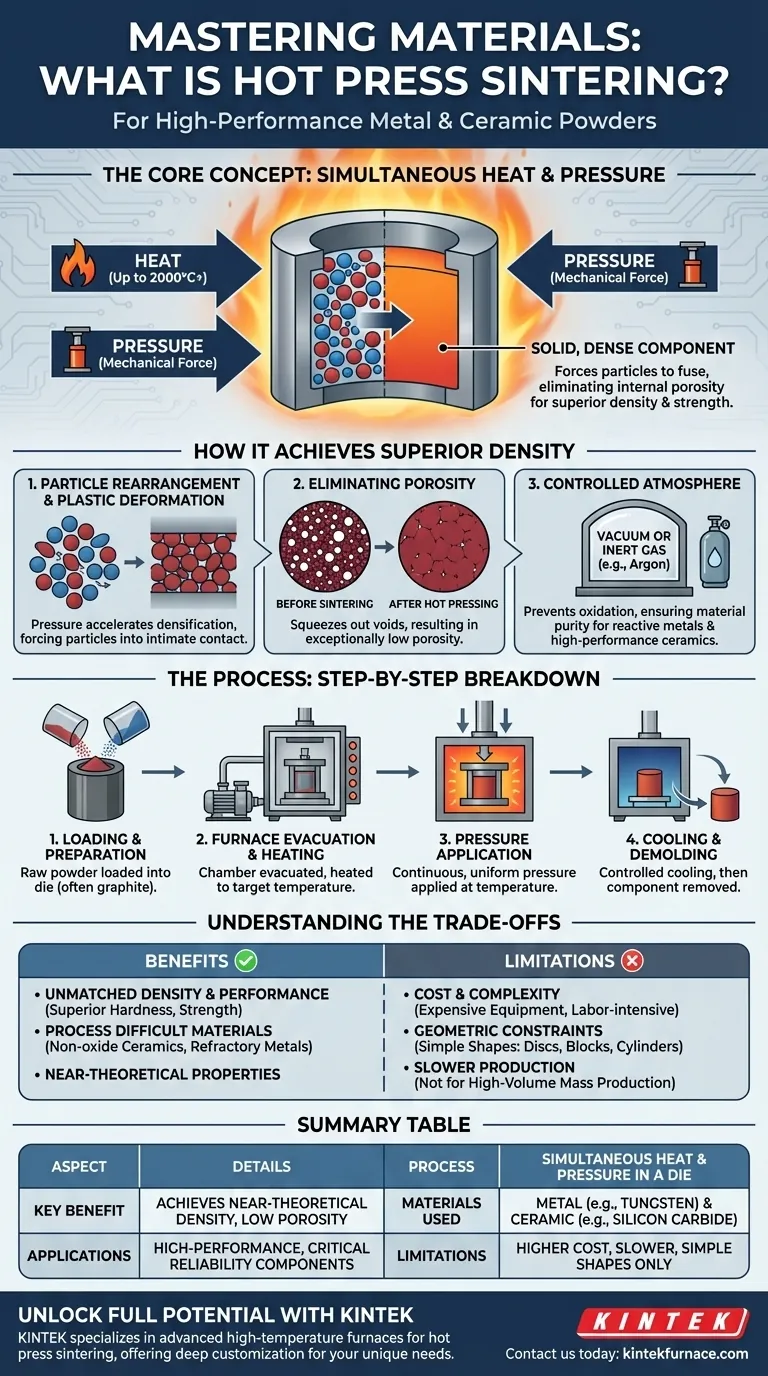

In essence, hot press sintering is an advanced manufacturing process that simultaneously applies high temperature and mechanical pressure to metal or ceramic powders inside a die. This combination forces the powder particles to fuse together, creating a solid component that is significantly denser and stronger than what can be achieved with heat alone. It is the go-to method for producing high-performance materials where eliminating internal porosity is critical.

The fundamental advantage of hot press sintering is its ability to achieve near-theoretical material density. By applying external pressure during heating, the process overcomes the kinetic barriers that limit conventional sintering, resulting in superior mechanical properties and performance.

How Hot Press Sintering Achieves Superior Density

The true value of this process lies in how it manipulates materials at a microscopic level. It doesn't just heat the powder; it actively compresses it to build a better final part.

The Role of Simultaneous Pressure

In conventional sintering, heat alone provides the energy for atoms to diffuse across particle boundaries, slowly closing the gaps between them.

Hot pressing adds a powerful mechanical force to this equation. This pressure accelerates densification by promoting particle rearrangement and inducing plastic deformation, physically forcing particles into intimate contact.

Eliminating Porosity

Porosity, or the presence of tiny voids, is the primary source of failure in many ceramic and metal components.

The external pressure applied during hot pressing effectively squeezes these voids out of the material's structure. This results in a final part with exceptionally low porosity and, therefore, much higher strength and reliability.

The Function of a Controlled Atmosphere

The process is typically conducted in a vacuum or an inert gas (like argon).

This controlled atmosphere is critical for preventing oxidation and other chemical reactions at high temperatures. This ensures the purity of the material, which is especially important for reactive metals or high-performance ceramics.

The Hot Press Sintering Process: A Step-by-Step Breakdown

While the concept is straightforward, the execution is a precise, multi-stage operation requiring specialized equipment.

Stage 1: Loading and Preparation

The raw metal or ceramic powder is loaded into a die, which is most commonly made of graphite due to its high-temperature strength and thermal shock resistance. This die defines the basic shape of the final component.

Stage 2: Furnace Evacuation and Heating

The die assembly is placed inside a vacuum hot press furnace. The chamber is evacuated to remove air, and the system is heated at a controlled rate to the target sintering temperature, which is below the material's melting point.

Stage 3: Pressure Application

Once the material reaches the appropriate temperature, a hydraulic or mechanical ram applies a continuous, uniform pressure to the powder through a plunger. The combination of heat and pressure is maintained for a specific duration to allow for full densification.

Stage 4: Cooling and Demolding

After the hold time, the pressure is released, and the furnace is cooled in a controlled manner to prevent thermal shock, which could crack the part. Once at a safe temperature, the dense, solid component is removed from the die.

Understanding the Trade-offs

Hot press sintering is a powerful tool, but it is not the universal solution for all applications. Understanding its advantages and limitations is key to using it effectively.

Benefit: Unmatched Density and Performance

The primary reason to choose hot pressing is to achieve material properties approaching their theoretical maximums. The resulting density leads to superior hardness, strength, and fracture toughness.

Benefit: Processing Difficult-to-Sinter Materials

Many advanced materials, such as non-oxide ceramics (e.g., silicon carbide, boron nitride) or refractory metals (e.g., tungsten), do not densify well with heat alone. Hot pressing provides the necessary driving force to consolidate them.

Limitation: Cost and Complexity

Vacuum hot press systems are expensive to purchase and operate. The process is also typically slower and more labor-intensive than high-volume methods like conventional press-and-sinter, making it less suitable for low-cost, mass-produced parts.

Limitation: Geometric Constraints

The process is best suited for producing simple shapes like discs, blocks, and cylinders, as the part geometry is limited by the die and the uniaxial direction of the applied pressure. Complex, three-dimensional shapes are difficult or impossible to produce directly.

Making the Right Choice for Your Goal

Selecting the right manufacturing process depends entirely on your project's technical and commercial requirements.

- If your primary focus is maximum material performance and density: Hot press sintering is the ideal choice for critical applications where strength, hardness, and reliability are non-negotiable.

- If your primary focus is processing non-sinterable or high-purity materials: This process provides the necessary energy to consolidate materials that cannot be effectively processed by other means.

- If your primary focus is high-volume, cost-effective production of simpler parts: A conventional press-and-sinter process or powder injection molding may offer a better balance of cost and performance.

Ultimately, hot press sintering is a precision tool for creating materials that perform at the absolute limit of their potential.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Simultaneous application of high temperature and mechanical pressure in a die. |

| Key Benefit | Achieves near-theoretical density, superior strength, and low porosity. |

| Materials Used | Metal powders (e.g., tungsten) and ceramic powders (e.g., silicon carbide). |

| Applications | High-performance components where maximum reliability and density are critical. |

| Limitations | Higher cost, slower process, and geometric constraints for simple shapes. |

Unlock the Full Potential of Your Materials with KINTEK

Are you working with metal or ceramic powders and need components with exceptional density and strength? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for hot press sintering. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental requirements, ensuring superior performance for your high-performance applications.

Contact us today to discuss how our solutions can enhance your material processing and achieve unparalleled results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- How are vacuum hot pressing sintering furnaces classified based on their service environment? Optimize Your Material Processing

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials