The structural integrity of copper-carbon nanotube (Cu-CNT) composites relies heavily on managing internal stresses that occur after the peak heating phase. Pressure maintenance and precise temperature control are crucial because they directly counteract the elastic recovery of carbon nanotubes and the mismatch in thermal expansion coefficients between the copper matrix and the fibers. Without these specific controls during the cooling phase, these internal physical forces effectively pull the composite apart, causing delamination defects.

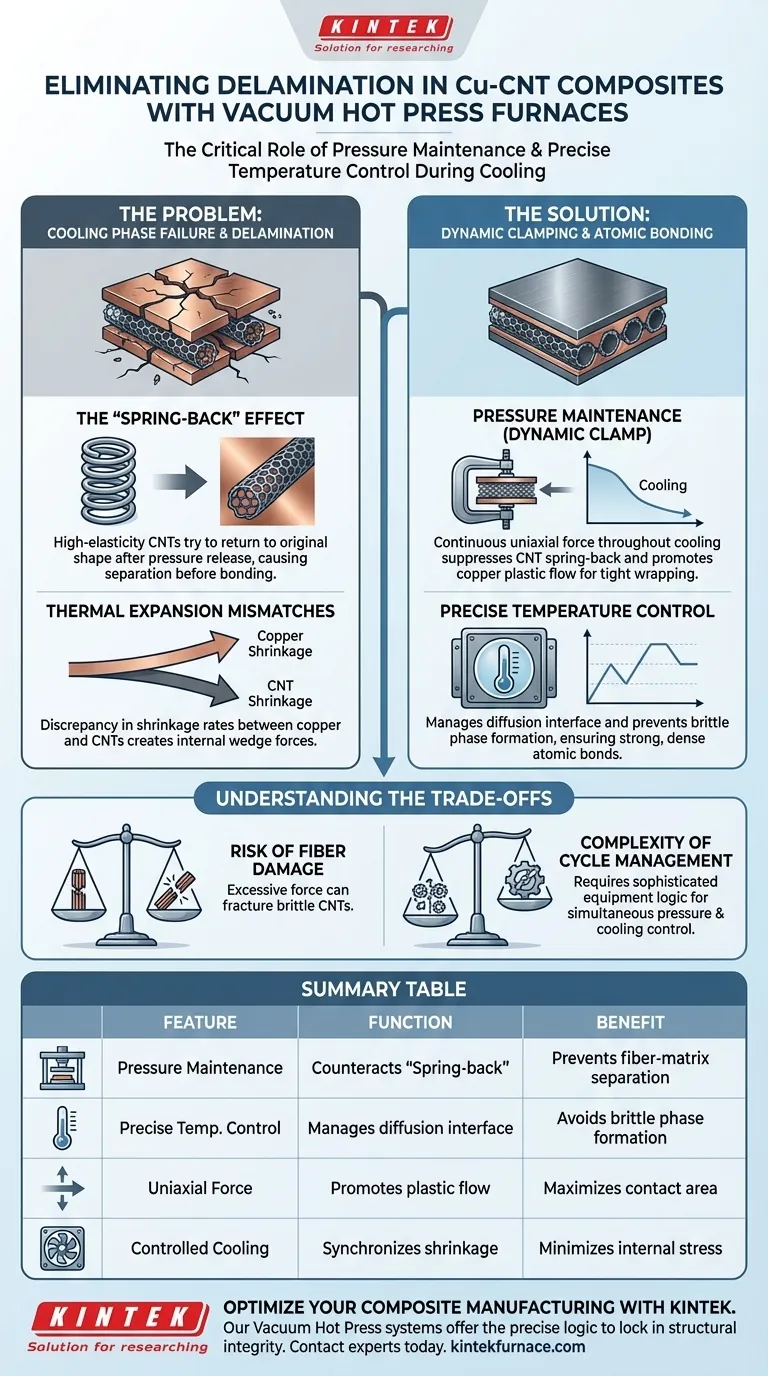

Core Takeaway: Delamination in Cu-CNT composites is largely a "cooling phase" failure caused by the "spring-back" effect of nanotubes and uneven material shrinkage. A vacuum hot press furnace eliminates this by maintaining pressure to clamp the materials together until the bond is permanent, while precise temperature control prevents the formation of weak or brittle interfaces.

The Mechanics of Delamination

To understand the solution, you must first understand the specific forces fighting against material cohesion.

The "Spring-Back" Effect

Carbon nanotubes (CNTs) possess high elasticity. During the hot pressing process, they are compressed under significant force.

However, CNTs tend to undergo elastic recovery—essentially trying to spring back to their original shape—once the pressure is released. If this occurs before the copper matrix has sufficiently bonded and solidified around them, the CNTs will separate from the matrix.

Thermal Expansion Mismatches

Copper and carbon nanotubes react differently to temperature changes.

As the composite cools, the copper matrix shrinks at a specific rate determined by its coefficient of thermal expansion. The CNTs shrink at a different rate. This discrepancy creates significant internal stress at the interface between the metal and the fiber, acting as a wedge that drives delamination.

How Pressure Maintenance Solves the Problem

The primary function of the vacuum hot press furnace in this context is to act as a dynamic clamp during the critical transition from hot to cold.

Continuous Clamping During Cooling

Unlike standard sintering, which may release pressure after the dwell time, a vacuum hot press furnace applies continuous pressure maintenance throughout the cooling phase.

This external force physically suppresses the elastic recovery of the CNTs. It holds the "springs" in their compressed state until the copper matrix has cooled enough to mechanically lock them in place.

Enhancing Plastic Flow

Pressure promotes the plastic flow of the metal matrix.

By maintaining uniaxial pressure, the furnace forces the copper to fill voids and wrap tightly around the CNTs. This maximizes the contact area, ensuring that when the material eventually solidifies, the mechanical interlock is strong enough to resist thermal stress.

The Necessity of Temperature Precision

While pressure manages physical alignment, temperature control manages the chemical and atomic integrity of the bond.

Controlling the Diffusion Interface

Precise temperature control is vital for managing the thickness and composition of the diffusion layer between the copper and the CNTs.

If the temperature varies even slightly, the interface may not form correctly. As noted in similar composite processing, specific temperatures are required to balance densification with interfacial reactions.

Preventing Brittle Phase Formation

Imprecise temperature control can lead to "over-processing."

Excessive temperatures can trigger reactions that form brittle compounds or cause local melting issues. While the copper matrix is the focus here, the principle applies universally: maintaining a precise temperature window avoids the generation of harmful phases that would weaken the interface and make it susceptible to delamination cracks.

Understanding the Trade-offs

While high pressure and strict temperature control are necessary, they introduce specific risks that must be managed.

Risk of Fiber Damage

Applying too much pressure, or applying it too abruptly, can physically damage the reinforcement material.

Just as precise pressure helps flow, excessive load can fracture brittle fibers or crush the CNT structure. The goal is to facilitate wrapping via creep, not to mechanically crush the components.

Complexity of Cycle Management

Maintaining pressure during cooling extends the process cycle and requires sophisticated equipment logic.

It is not enough to simply "turn off" the furnace. The equipment must actively manage the cooling rate and pressure curve simultaneously, which increases the complexity of the operation and the cost of the machinery.

Making the Right Choice for Your Goal

When configuring your vacuum hot press process for Cu-CNT composites, consider the following regarding your specific performance targets:

- If your primary focus is Structural Integrity (No Delamination): Prioritize pressure maintenance during the cooling phase. Ensure your equipment can sustain high uniaxial force well below the solidification temperature to counteract CNT elastic recovery.

- If your primary focus is Thermal/Electrical Conductivity: Prioritize temperature precision. You must hit the exact window that ensures dense bonding without overheating, which could form brittle phases that interrupt conductivity paths.

Success in fabricating Cu-CNT composites is less about peak heat, and more about how strictly you control the environment while the material cools and sets.

Summary Table:

| Feature | Function in Cu-CNT Processing | Benefit to Material Integrity |

|---|---|---|

| Pressure Maintenance | Counteracts "Spring-back" effect of nanotubes | Prevents fiber-matrix separation and delamination |

| Precise Temperature Control | Manages diffusion interface and atomic bonding | Avoids brittle phase formation and ensures density |

| Uniaxial Force | Promotes plastic flow of copper matrix | Maximizes contact area and mechanical interlocking |

| Controlled Cooling | Synchronizes shrinkage rates | Minimizes internal stress from thermal expansion mismatch |

Optimize Your Composite Manufacturing with KINTEK

Don't let delamination compromise your advanced material research. KINTEK provides industry-leading Vacuum Hot Press systems, alongside our expert R&D and manufacturing of Muffle, Tube, Rotary, and CVD furnaces. Whether you are working with Cu-CNT composites or specialized ceramics, our systems offer the precise pressure and temperature logic required to lock in structural integrity.

Ready to achieve superior bonding? Contact our experts today to discuss a customizable solution for your unique high-temp laboratory needs.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How do temperature, pressure and holding time affect hot pressed product density? Optimize Your Process for Maximum Efficiency

- What applications does Vacuum Hot Press technology have in the electronics and semiconductor industry? Unlock High-Performance Component Manufacturing

- How does vacuum hot press sintering compare to SPS for Fe-Cu composites? Achieve Superior Industrial Quality

- What are the main components of a vacuum hot press furnace? Unlock Precision Material Processing

- How does the vacuum system in these furnaces work? Achieve Purity and Performance in High-Temperature Processes

- What are the advantages of SPS over hot pressing for high-entropy alloys? Achieve Superior Density and Microstructure

- What function do high-strength graphite molds serve? Essential Roles in Vacuum Hot Pressing Aluminum Matrix Composites

- What is the primary function of a vacuum hot press furnace in the preparation of Fe-based amorphous alloy/aluminum microlaminated composites? Achieve Perfect Solid-State Bonding