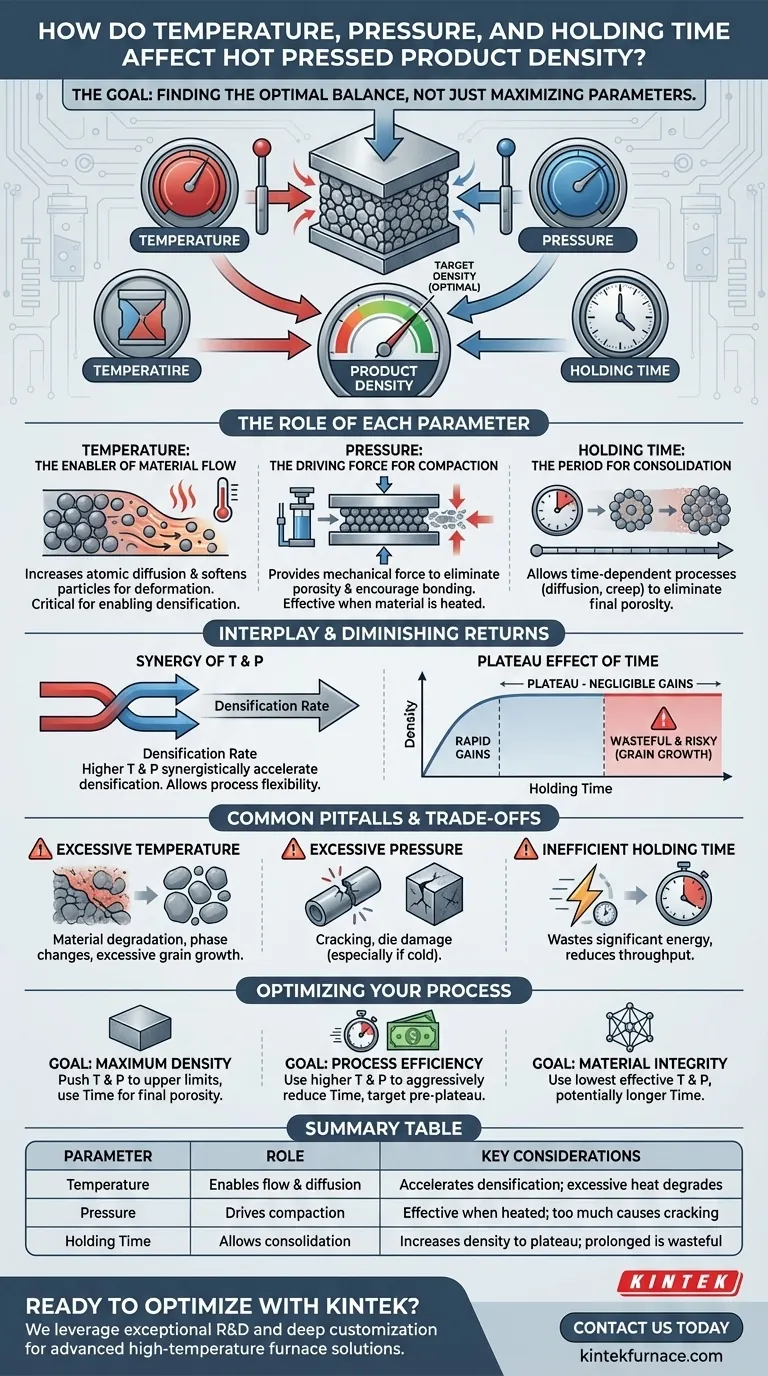

In hot pressing, temperature, pressure, and holding time are the primary levers for controlling final product density. Both higher temperatures and greater pressures accelerate the densification process, while holding time increases density up to a point of diminishing returns, after which it provides no significant benefit.

The core challenge of hot pressing is not simply maximizing these parameters, but finding the optimal balance between them. This achieves your target density efficiently without wasting energy or compromising the material's final properties.

The Role of Each Process Parameter

To optimize your process, you must first understand the distinct role each variable plays in consolidating the material.

Temperature: The Enabler of Material Flow

Temperature is the most critical parameter for enabling densification. As you heat a material, you increase atomic diffusion and soften the particles.

This softening makes the material more plastic, allowing it to deform and flow under pressure to fill the voids between particles.

Pressure: The Driving Force for Compaction

Pressure provides the external mechanical force needed to compact the material. It forces particles together, eliminating porosity and encouraging bonding.

Pressure is most effective when the material has been sufficiently heated. Applying high pressure to a cold or insufficiently heated material is ineffective and can lead to cracking.

Holding Time: The Period for Consolidation

Holding time is the duration for which the peak temperature and pressure are maintained. This period allows time-dependent processes like diffusion and creep to occur.

These processes are essential for eliminating the final, smaller pockets of porosity and achieving a fully dense state.

Understanding the Interplay and Diminishing Returns

The parameters do not work in isolation. Their interaction dictates the efficiency and outcome of the entire process.

The Synergy of Temperature and Pressure

Higher temperatures and pressures both act to accelerate densification. This creates a synergistic effect.

Increasing the temperature can reduce the amount of pressure needed to achieve a certain density, and vice versa. This interplay allows for process flexibility based on material and equipment limitations.

The Plateau Effect of Holding Time

The rate of densification is not linear. It is typically rapid at the beginning of the hold period as large voids are quickly eliminated.

As the material approaches its theoretical maximum density, the process slows dramatically. Extending the holding time beyond this "plateau" yields negligible gains in density but continues to consume energy and risks undesirable effects like grain growth.

Common Pitfalls and Trade-offs

Pushing parameters to their absolute maximums can be counterproductive and lead to defects in the final part.

Excessive Temperature

While high temperature aids densification, too much can be detrimental. It can cause material degradation, unwanted phase changes, or excessive grain growth, which can reduce the final product's strength and toughness.

Excessive Pressure

Applying too much pressure, especially early in the cycle before the material is uniformly heated, can cause cracking in the part or damage the pressing die. It creates high-stress points rather than uniform compaction.

Inefficient Holding Time

The most common inefficiency is an overly long holding time. This wastes significant energy and reduces production throughput with no corresponding improvement in product quality.

Optimizing Your Hot Pressing Process

Your ideal parameters depend entirely on your primary goal. Use these principles as a starting point for developing your specific process.

- If your primary focus is achieving maximum possible density: Push temperature and pressure toward the upper limits recommended for the material, using holding time to eliminate final porosity.

- If your primary focus is process efficiency (speed and cost): Utilize higher temperatures and pressures to aggressively reduce the required holding time, targeting the point just before the densification rate plateaus.

- If your primary focus is preserving material integrity (e.g., fine grain size): Use the lowest effective temperature and pressure possible, potentially accepting a longer holding time to achieve the target density without inducing material damage.

Mastering hot pressing is an exercise in controlling the interplay of heat, force, and time to achieve your desired outcome repeatably and efficiently.

Summary Table:

| Parameter | Role in Densification | Key Considerations |

|---|---|---|

| Temperature | Enables material flow and atomic diffusion | Higher temperatures accelerate densification; excessive heat can cause degradation |

| Pressure | Drives compaction and eliminates porosity | Effective when material is heated; too much pressure may lead to cracking |

| Holding Time | Allows time-dependent consolidation processes | Increases density up to a plateau; prolonged times waste energy with minimal gains |

Ready to optimize your hot pressing process with tailored solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve superior density and efficiency. Contact us today to discuss how we can enhance your lab's performance!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the advantages of using vacuum hot press furnaces over traditional furnaces? Achieve Superior Material Quality and Performance

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What safety precautions and maintenance requirements are necessary for vacuum hot press furnaces? Ensure Safe, Reliable Operation

- What are the applications of hot pressing? Achieve Maximum Material Performance