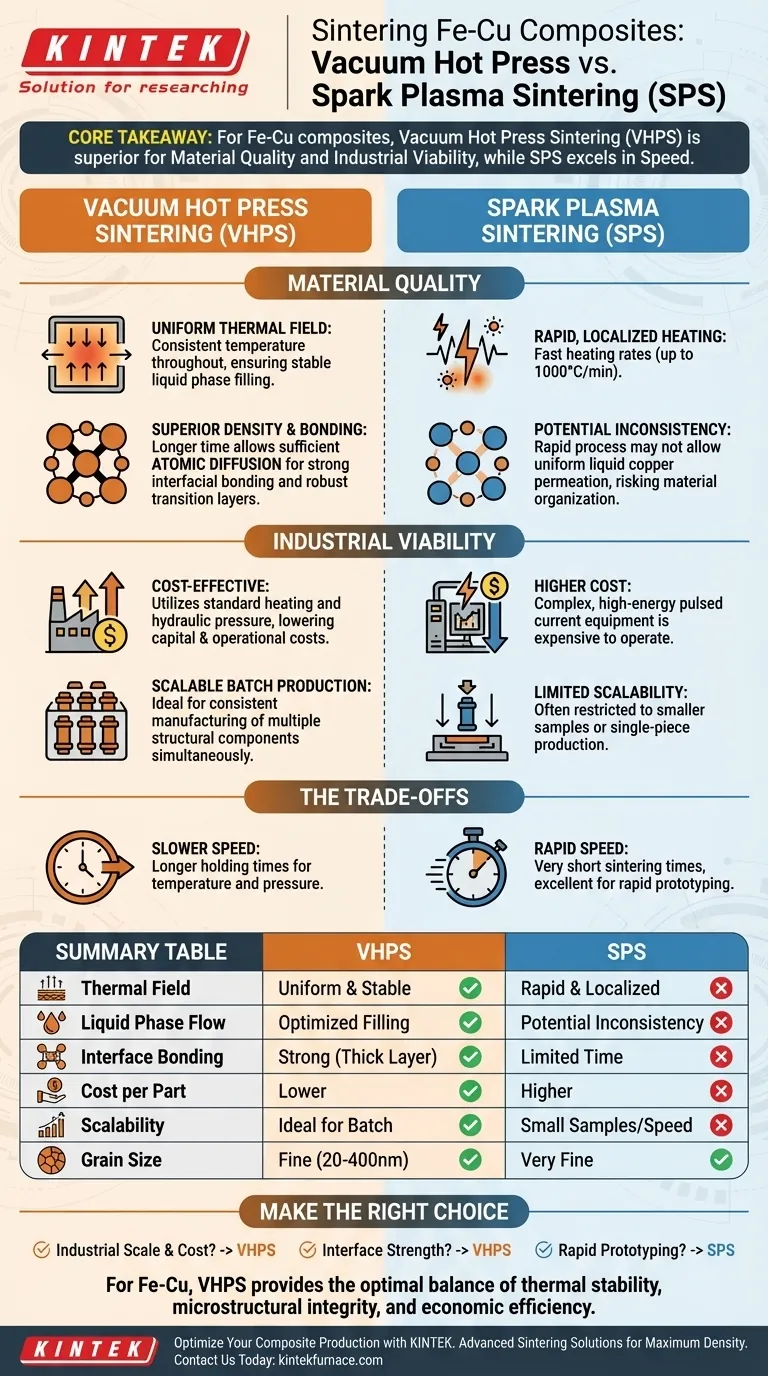

For the production of Fe-Cu composites, vacuum hot press sintering is technically superior to Spark Plasma Sintering (SPS) regarding material quality and industrial viability. While SPS offers rapid processing speeds, vacuum hot press sintering delivers the uniform thermal environment necessary for optimal density and structural integrity in Fe-Cu systems.

Core Takeaway While Spark Plasma Sintering (SPS) excels in speed, vacuum hot press sintering is the preferred method for Fe-Cu composites because it provides a stable liquid phase and uniform thermal field. This results in higher density, better material organization, and a significantly lower production cost suitable for industrial scaling.

Material Quality and Microstructure

Achieving Superior Density

The primary advantage of vacuum hot press sintering for Fe-Cu composites is the creation of a uniform thermal field. Unlike the rapid, pulsed heating of SPS, hot pressing maintains a consistent temperature profile throughout the material.

This uniformity allows for a more stable liquid phase filling time. In an Fe-Cu system, ensuring the copper liquid phase adequately fills the voids between iron particles is critical for achieving high density.

Control of Atomic Diffusion

Vacuum hot press sintering typically utilizes longer holding times for both temperature and pressure compared to SPS.

This extended duration facilitates sufficient atomic diffusion reactions. It allows for the formation of a thicker, more distinct diffusion transition layer between the iron and copper, which is essential for strong interfacial bonding.

Regulating Interface Evolution

The process characteristics of vacuum hot press sintering allow for better regulation of the interface evolution process.

Because the process is dominated by thermal diffusion over a longer period, researchers and engineers can more clearly observe and control how the materials bond. This leads to more predictable mechanical strength in the final composite.

Industrial Feasibility and Cost

Cost-Effectiveness

For the production of structural components, vacuum hot press sintering is generally lower in cost than SPS technology.

SPS equipment is often complex and expensive to operate due to the high-energy pulsed current requirements. Vacuum hot pressing utilizes standard heating elements and hydraulic pressure, reducing capital and operational expenditures.

Scalability for Batch Production

Vacuum hot press sintering is specifically identified as being more suitable for industrial batch production.

The stability of the process allows for the consistent manufacturing of multiple structural components simultaneously. SPS is often limited to smaller sample sizes or single-piece production, making it less viable for large-scale manufacturing of Fe-Cu parts.

Understanding the Trade-offs

The Speed Differential

SPS utilizes Joule heating and field effects to achieve extremely high heating rates (up to 1000°C/min). This results in very short sintering times compared to the vacuum hot press method.

However, for Fe-Cu composites, this speed can be a disadvantage. The rapid heating may not allow sufficient time for the liquid copper phase to permeate the iron matrix uniformly, potentially leading to inconsistent material organization.

Grain Size Considerations

A general advantage of vacuum hot press sintering over traditional cold pressing-sintering is the prevention of grain coarsening.

By combining sintering and densification into a single step under vacuum, the process creates fine-grained materials (20-400 nm) with superior wear resistance. While SPS also controls grain growth via speed, the vacuum hot press achieves this while maintaining the diffusion time needed for Fe-Cu bonding.

Making the Right Choice for Your Goal

To select the correct sintering method for your specific project, consider the following production priorities:

- If your primary focus is Industrial Scale and Cost: Choose vacuum hot press sintering to ensure uniform density and economic feasibility for batch production.

- If your primary focus is Interface Strength: Choose vacuum hot press sintering to allow sufficient atomic diffusion and the formation of robust transition layers.

- If your primary focus is Rapid Prototyping Speed: Choose SPS, but be aware that you may sacrifice material uniformity and density compared to hot pressing.

For Fe-Cu composites, vacuum hot press sintering provides the optimal balance of thermal stability, microstructural integrity, and economic efficiency.

Summary Table:

| Feature | Vacuum Hot Press Sintering | Spark Plasma Sintering (SPS) |

|---|---|---|

| Thermal Field | Uniform and Stable | Rapid and Localized |

| Liquid Phase Flow | Optimized Filling Time | Potential for Inconsistency |

| Interface Bonding | Strong (Thick Diffusion Layer) | Limited Diffusion Time |

| Cost per Part | Lower (Industrial Efficiency) | Higher (Equipment/Power) |

| Scalability | Ideal for Batch Production | Best for Small Samples/Speed |

| Grain Size | Fine (20-400 nm) | Very Fine (Fast Processing) |

Optimize Your Composite Production with KINTEK

Ensure your Fe-Cu composites achieve maximum density and structural integrity with our advanced sintering solutions. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, Muffle, Tube, Rotary, and CVD systems, all fully customizable to meet your unique laboratory or industrial needs.

Ready to elevate your material quality? Contact our specialists today to find the perfect furnace for your application.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What components are used in hot press furnaces to apply pressure? Essential Parts for Precise High-Temp Compression

- Why are precision vacuum ovens required for reactor hot-press bonding? Ensure Leak-Free High-Pressure Integrity

- What is the process of vacuum laminating? Create Strong, Lightweight Composite Parts

- How do graphite molds function during the SPS of Ti-6Al-4Zr-4Nb alloys? Mastering Dual-Action Sintering

- What role does hot pressing play in materials science? Achieve High-Density, Complex Parts Efficiently

- What are the primary technical advantages of using a Spark Plasma Sintering (SPS) system? Achieve Superior Sintering

- How does the high-precision temperature control system of a sintering furnace influence nano-copper microstructure?

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing