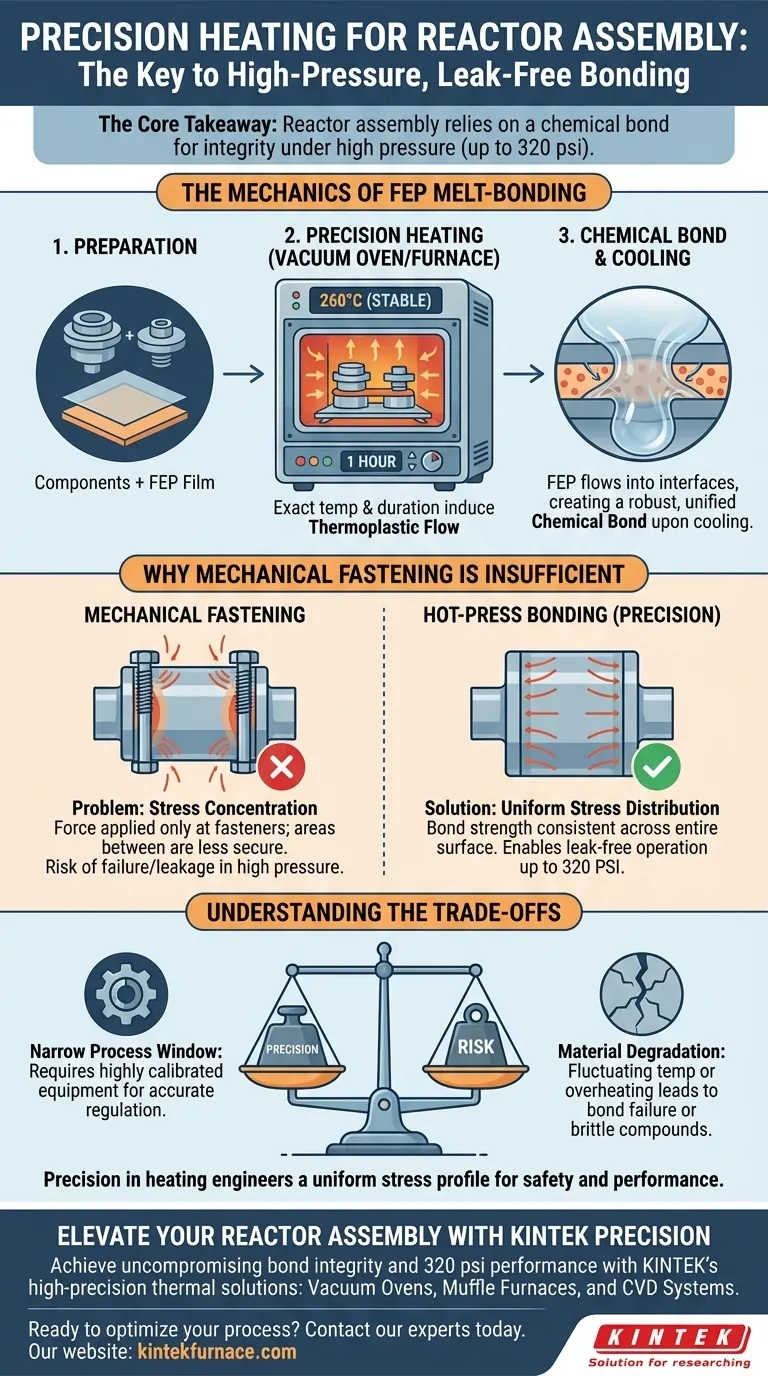

Precision heating equipment is strictly required to accurately control the melt-bonding process of Fluorinated Ethylene Propylene (FEP) films used in reactor assembly. By maintaining a specific, stable environment—typically 260°C for exactly one hour—these furnaces allow the FEP to undergo thermoplastic flow, penetrating component interfaces to create a bond that mechanical fastening cannot achieve.

The Core Takeaway Reactor assembly relies on a chemical bond rather than mechanical force to ensure integrity under high pressure. Precision vacuum ovens are essential to facilitate the thermoplastic flow of FEP films, creating a unified, leak-free component capable of withstanding pressures up to 320 psi.

The Mechanics of FEP Melt-Bonding

Achieving Thermoplastic Flow

The central objective of using a precision oven is to induce thermoplastic flow.

FEP films must be heated to a precise target temperature of 260°C and held there for a specific duration, such as one hour. This precise thermal exposure causes the film to soften and flow into the microscopic interfaces of the aligned reactor components.

Creating a Robust Chemical Bond

Once the heating cycle is complete, the cooling process solidifies the FEP.

This creates a robust chemical bond between the components. Unlike a temporary seal, this process fuses the parts into a single, cohesive unit designed for high-performance operation.

Why Mechanical Fastening is Insufficient

The Problem with Stress Concentration

Standard mechanical fastening, such as using bolts or screws, creates points of high stress.

Force is applied only where the fasteners are located, leaving the areas between them less secure. In high-pressure environments, these uneven stress concentrations can lead to structural failure or leakage.

Uniform Stress Distribution

Hot-press bonding provides uniform stress distribution across the entire bonded surface.

Because the FEP film penetrates the entire interface, the bond strength is consistent throughout the assembly. This uniformity is the key factor that allows the reactor to operate leak-free at high pressures, specifically up to 320 psi.

Understanding the Trade-offs

Precision vs. Simplicity

While hot-press bonding offers superior performance, it demands a much narrower process window than mechanical assembly.

Requires highly calibrated equipment. Standard ovens that fluctuate in temperature cannot be used; accurate regulation is necessary to ensure atomic diffusion or polymer flow occurs without overheating the materials.

Risk of Material Degradation

If the temperature is not controlled precisely, the bond will fail.

In general bonding contexts, excessive heat can lead to local melting of the substrate matrix or the formation of brittle compounds. Precision equipment mitigates this risk by ensuring the temperature stays exactly within the range required for the bond, preserving the mechanical properties of the joint.

Making the Right Choice for Your Goal

To ensure the success of your reactor assembly, apply these principles based on your specific requirements:

- If your primary focus is High-Pressure Integrity: Prioritize precision ovens that can maintain 260°C without fluctuation to guarantee the FEP creates a leak-free seal capable of 320 psi.

- If your primary focus is Material Longevity: Use vacuum environments to prevent oxidation and precise thermal ramping to avoid degrading the component materials during the bonding phase.

Precision in heating is not just about melting the film; it is about engineering a uniform stress profile that guarantees safety and performance.

Summary Table:

| Feature | Mechanical Fastening | Hot-Press Bonding (Precision Oven) |

|---|---|---|

| Bond Type | Physical/Mechanical | Chemical/Thermoplastic Flow |

| Stress Distribution | Concentrated at fasteners | Uniform across surface |

| Pressure Rating | Lower, prone to leaks | Up to 320 psi (Leak-free) |

| Equipment Requirement | Manual tools | Precision 260°C Vacuum/Heating Oven |

| Material Integrity | Potential deformation | Preserved via controlled thermal window |

Elevate Your Reactor Assembly with KINTEK Precision

Achieve uncompromising bond integrity and 320 psi performance with KINTEK’s high-precision thermal solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum Ovens, Muffle Furnaces, and CVD systems designed to meet the strict 260°C process windows required for FEP melt-bonding. Whether you need standard lab heating or a fully customizable system for unique industrial scales, KINTEK ensures uniform heat distribution and oxidation prevention for your most critical components.

Ready to optimize your hot-press bonding process? Contact our experts today to find the perfect furnace solution.

Visual Guide

References

- Chan Ho Song, Chan Pil Park. Flow Reactor for Sustainable Electrosynthesis Fabricated via Cost‐Effective Electroplating and Adhesive Bonding. DOI: 10.1002/cssc.202501123

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the technical advantages of using an SPS sintering furnace? Elevate Al2O3-TiC Material Performance

- How does the mechanical pressure of a Vacuum Hot Press Furnace improve composite density? Elevate Performance Today

- What types of manufacturing solutions are created for composite material processing? Optimize Your Production with Advanced Methods

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- Why must mold materials in FAST/SPS systems possess high mechanical strength? Ensuring Safety and Precision

- What are the temperature-based classifications for vacuum hot pressing sintering furnaces? Choose the Right Furnace for Your Materials

- What are the main components of a vacuum hot press furnace? Unlock Precision Material Processing

- How does a Vacuum Hot-Pressing Furnace facilitate the densification of CaF2? Achieve High Optical Transparency