At their core, manufacturing solutions for composite materials are designed to shape and solidify the material under highly controlled conditions. The primary methods involve complete manufacturing plants centered around vacuum-thermoforming machines, which utilize both hot and cold vacuum pressing to form the final part.

The specific machine is only one part of the equation. The real goal of these manufacturing solutions is to master the interplay of heat, pressure, and time to produce consistent, high-quality composite parts while minimizing errors and cost.

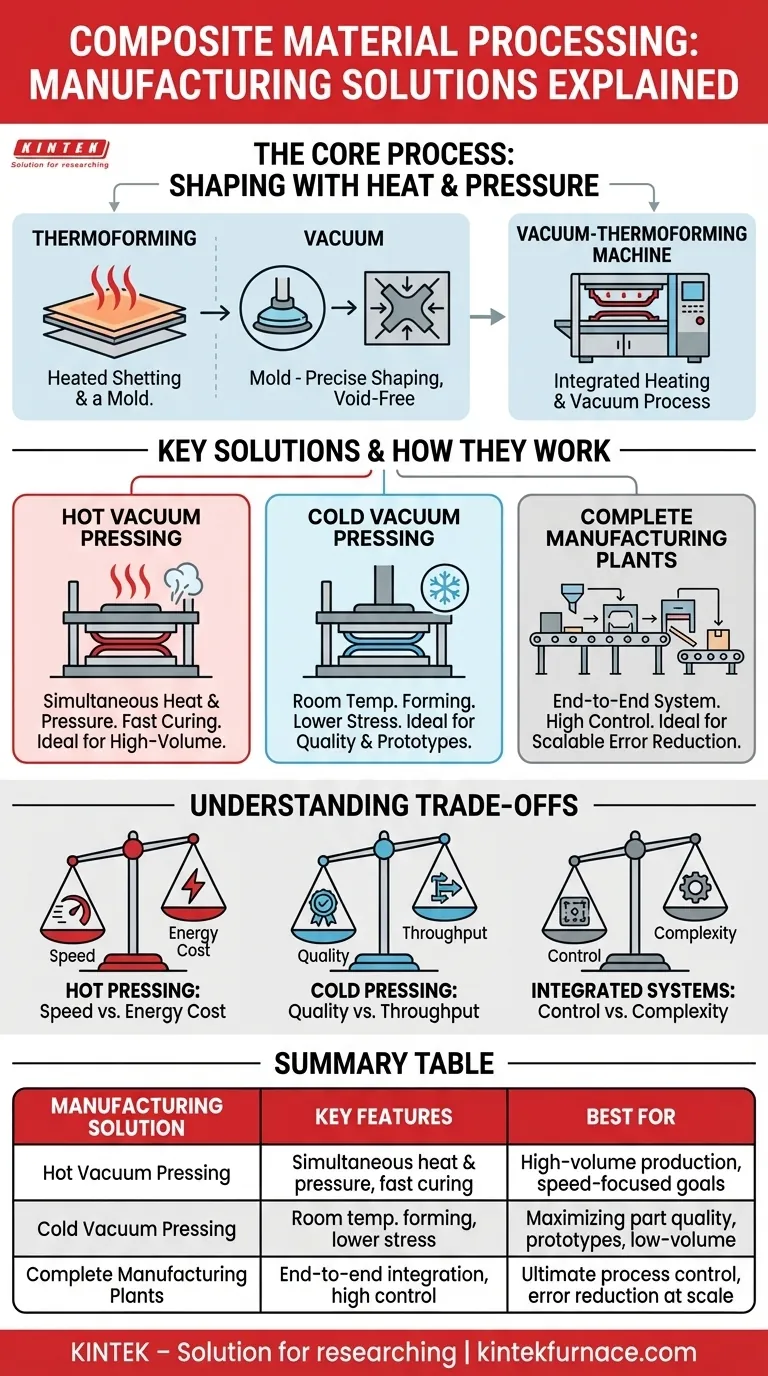

The Core Process: Shaping Composites with Heat and Pressure

Modern composite manufacturing revolves around a process known as thermoforming. This technique uses a combination of temperature and vacuum to precisely shape composite sheets or preforms into a desired geometry.

What is Thermoforming?

Thermoforming is a manufacturing process where a plastic or composite sheet is heated to a pliable forming temperature. Once malleable, it is formed to a specific shape in a mold and then trimmed to create a usable product.

The Critical Role of Vacuum

A vacuum is applied to pull the heated material tightly against the mold's surface. This ensures every detail and contour of the mold is perfectly replicated, removing trapped air and ensuring a dense, void-free part.

How Vacuum-Thermoforming Machines Work

These machines integrate the heating and vacuum stages into a single, controlled process. The composite material is heated, transferred to the molding station, and then a vacuum is applied to draw it into or over the mold, forming the final part.

Key Manufacturing Solutions Explained

The choice of solution depends on the material, the complexity of the part, and production goals. The two main approaches are hot and cold pressing.

Hot Vacuum Pressing

In this method, both heat and pressure are applied simultaneously. The press heats the composite material to its curing temperature while the vacuum removes air and a press applies mechanical force. This accelerates the curing cycle significantly.

This process is ideal for high-volume production where cycle time is a critical factor.

Cold Vacuum Pressing

In cold pressing, the initial forming and vacuum application may happen at or near room temperature. The part is consolidated under vacuum and may be cured later in an oven without direct pressure from the press itself.

This approach is often used for larger structures or materials that are sensitive to rapid temperature changes, prioritizing material integrity over speed.

Complete Manufacturing Plants

The most advanced solutions are complete, integrated manufacturing plants. These are not just individual machines but end-to-end systems that handle material preparation, forming, curing, and finishing.

These "individual solutions" are custom-built to optimize a specific production process, aiming to maximize quality and minimize cost for a particular composite part.

Understanding the Trade-offs

Every manufacturing decision involves balancing competing factors. Understanding these is key to selecting the right process.

Hot Pressing: Speed vs. Energy Cost

The primary advantage of hot pressing is speed, leading to higher throughput. However, these systems have higher upfront capital costs and consume more energy, which can increase the cost per part.

Cold Pressing: Quality vs. Throughput

Cold pressing is generally slower due to longer curing cycles. The trade-off is often lower internal stress on the part and lower energy costs. It is well-suited for prototypes or low-volume production where dimensional stability is paramount.

Integrated Systems: Control vs. Complexity

A complete manufacturing plant offers unparalleled control over the entire process, drastically reducing the potential for human error. The downside is significant initial investment and complexity, requiring specialized knowledge to operate and maintain.

Making the Right Choice for Your Goal

Your optimal solution depends entirely on your project's primary objective.

- If your primary focus is high-volume production: Hot vacuum pressing is the most effective solution due to its fast cycle times.

- If your primary focus is maximizing part quality and minimizing internal stress: A cold vacuum pressing process is often the superior choice.

- If your primary focus is ultimate process control and minimizing errors at scale: An integrated, complete manufacturing plant provides the most robust and repeatable results.

By aligning your manufacturing process with your specific goals, you can unlock the full performance and economic potential of composite materials.

Summary Table:

| Manufacturing Solution | Key Features | Best For |

|---|---|---|

| Hot Vacuum Pressing | Simultaneous heat and pressure, fast curing | High-volume production, speed-focused goals |

| Cold Vacuum Pressing | Room temperature forming, lower stress | Maximizing part quality, prototypes, low-volume |

| Complete Manufacturing Plants | End-to-end integration, high control | Ultimate process control, error reduction at scale |

Ready to enhance your composite material processing? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, supported by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your production with reliable, customized solutions!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

People Also Ask

- How does hot pressing work? Achieve Maximum Density and Strength for Advanced Materials

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing