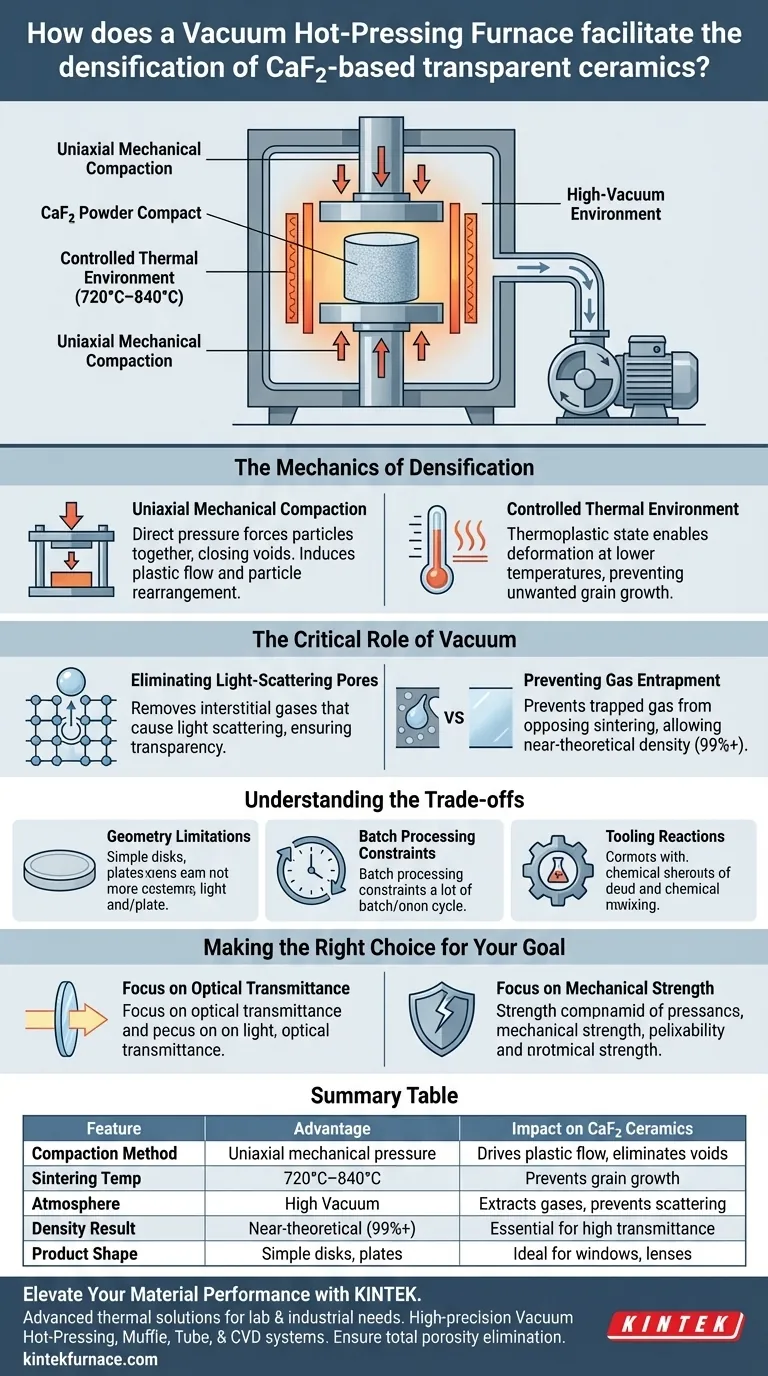

A Vacuum Hot-Pressing Furnace facilitates the densification of CaF2-based transparent ceramics by effectively combining simultaneous conductive heating with uniaxial mechanical compaction. This dual-action approach drives particle rearrangement and plastic flow, allowing the material to reach near-theoretical density at significantly lower temperatures (typically 720°C–840°C) than conventional sintering methods. By processing in a vacuum, the system also removes interstitial gases, eliminating the residual pores that cause light scattering and compromise optical transparency.

Core Takeaway Achieving high optical transmittance in ceramics requires the total elimination of internal porosity. Vacuum hot-pressing solves this by substituting extreme heat with mechanical pressure, forcing material densification while simultaneously extracting trapped gases to prevent pore formation.

The Mechanics of Densification

Uniaxial Mechanical Compaction

The primary driver of densification in this process is mechanical force, typically applied via hydraulic rams. Unlike pressureless sintering, which relies solely on thermal energy and surface tension, hot-pressing applies direct external pressure.

This pressure physically forces the CaF2 powder particles together. It induces plastic flow and particle rearrangement, effectively closing voids between particles that would otherwise remain open.

Controlled Thermal Environment

While pressure does the heavy lifting, temperature remains a critical variable. The furnace operates within a specific window, cited in your primary context as 720°C–840°C for these materials.

At these temperatures, the ceramic powder becomes thermoplastic. This state allows the material to deform under the applied pressure, filling gaps and densifying rapidly without requiring the extreme heat that triggers unwanted grain growth.

The Critical Role of Vacuum

Eliminating Light-Scattering Pores

For a ceramic to be transparent, it must be virtually free of porosity. Even microscopic pores act as scattering centers, turning a clear material opaque or milky.

The high-vacuum environment continuously evacuates the chamber during the heating phase. This removes adsorbed gases and volatile impurities from the powder surfaces before the pores close off.

Preventing Gas Entrapment

If these gases were not removed prior to densification, they would become trapped inside the closing pores. Trapped gas creates internal pressure that opposes sintering, making it impossible to achieve the 99%+ relative density required for high transmittance.

Understanding the Trade-offs

Geometry Limitations

While effective, uniaxial hot-pressing is geometrically constrained. Because pressure is applied from one direction (usually top and bottom), this method is generally limited to simple shapes like flat disks, plates, or cylinders. Complex 3D geometries often require post-processing or alternative sintering methods.

Batch Processing Constraints

Vacuum hot-pressing is inherently a batch process, not a continuous one. The cycle times for heating, holding under pressure, and cooling can be lengthy. This generally lowers throughput and increases the cost-per-unit compared to pressureless sintering.

Tooling Reactions

The process typically utilizes graphite dies to withstand high temperatures and pressure. At elevated temperatures, there is a risk of carbon diffusion or chemical reaction with the ceramic material, which may require subsequent surface grinding or polishing to remove.

Making the Right Choice for Your Goal

To maximize the utility of a Vacuum Hot-Pressing Furnace for CaF2 ceramics, consider your specific end-goals:

- If your primary focus is Optical Transmittance: Prioritize a high-vacuum hold period before applying maximum pressure to ensure all interstitial gases are fully evacuated, preventing residual porosity.

- If your primary focus is Mechanical Strength: optimize the pressure-temperature ratio to achieve full density at the lowest possible temperature, as this inhibits grain growth and preserves the material's fine microstructure.

The synergy of vacuum and pressure is the definitive method for producing high-performance transparent ceramics where porosity cannot be tolerated.

Summary Table:

| Feature | Vacuum Hot-Pressing Advantage | Impact on CaF2 Ceramics |

|---|---|---|

| Compaction Method | Uniaxial mechanical pressure | Drives plastic flow and eliminates internal voids |

| Sintering Temp | 720°C–840°C (Low temperature) | Prevents grain growth while maintaining microstructure |

| Atmosphere | High Vacuum environment | Extracts interstitial gases to prevent light scattering |

| Density Result | Near-theoretical (99%+) | Essential for high optical transmittance and clarity |

| Product Shape | Simple disks, plates, cylinders | Ideal for optical windows and lens blanks |

Elevate Your Material Performance with KINTEK

Maximize the optical transmittance and mechanical strength of your transparent ceramics with KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-precision Vacuum Hot-Pressing, Muffle, Tube, and CVD systems tailored for specialized lab and industrial needs. Whether you require precise uniaxial compaction or customizable high-temp furnaces, our equipment ensures total porosity elimination for your most demanding applications.

Ready to optimize your densification process? Contact our technical experts today to discuss your unique project requirements!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- Why are vacuum presses considered versatile tools in various industries? Achieve Perfect Lamination and Forming

- What are the advantages of using hot pressing in manufacturing? Achieve Superior Quality and Precision

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- What is the hot pressing process in material densification? Achieve Superior Density for Advanced Materials

- What is the necessity of maintaining a high vacuum environment during AZ31 sintering? Prevent Oxidation and Porosity

- What are the advantages of using a HIP sintering system over conventional sintering for Bismuth Telluride composites?

- What is the primary function of a vacuum hot pressing sintering furnace? Achieving High-Density CoCrFeNi(Cu) Coatings