At its core, vacuum hot pressing is a manufacturing process that simultaneously applies high temperature and mechanical pressure to a material inside a vacuum. This combination forces the material's particles to bond and densify, creating exceptionally strong and pure components by eliminating internal voids and preventing oxidation. The process generally involves loading material into a vacuum chamber, evacuating the air, heating the material to a specific sintering temperature, applying pressure, and then carefully cooling the final part.

The fundamental advantage of vacuum hot pressing is its ability to overcome the limitations of simple heating. By adding mechanical pressure in a pure vacuum environment, the process physically compacts the material, eliminating porosity and preventing contamination to achieve material properties that are otherwise unattainable.

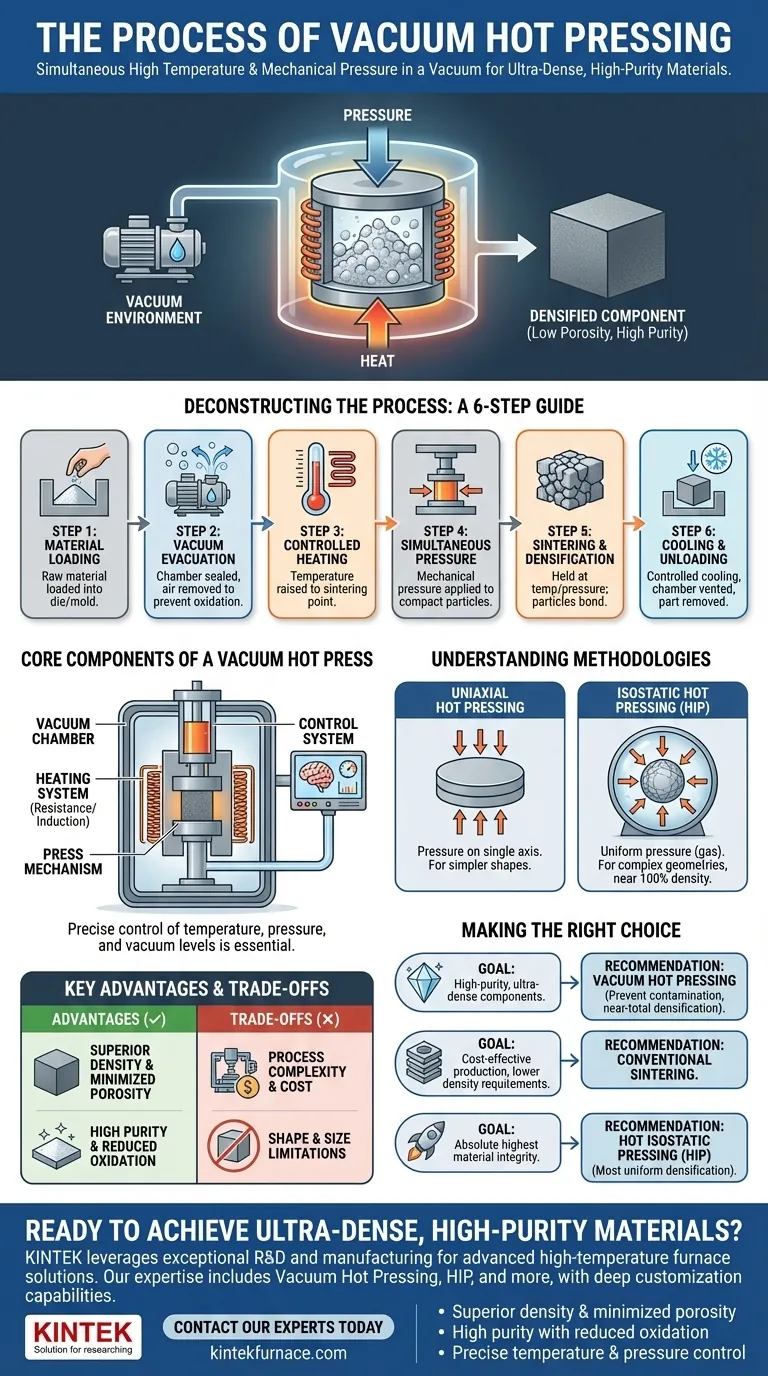

Deconstructing the Process: A Step-by-Step Guide

To understand how vacuum hot pressing achieves its results, it is best to break it down into its distinct operational stages.

Step 1: Material Loading

The raw material, typically in powder form, is loaded into a die or mold. This assembly is then carefully placed inside the vacuum chamber of the press.

Step 2: Vacuum Evacuation

The chamber is sealed, and a powerful vacuum system removes the air and other atmospheric gases. This crucial step prevents the material from reacting with oxygen or other contaminants at high temperatures.

Step 3: Controlled Heating

A heating system, often using electrical resistance or induction, raises the material's temperature to just below its melting point. This is the sintering temperature, where the material's particles become reactive enough to bond together.

Step 4: Simultaneous Pressure Application

As the material reaches the target temperature, a press mechanism applies mechanical pressure. This force physically pushes the particles together, collapsing the voids between them and accelerating the bonding process.

Step 5: Sintering and Densification

The material is held at the specified temperature and pressure for a set duration. During this "dwell time," the particles diffuse and fuse, forming a solid, dense mass with minimal internal porosity.

Step 6: Controlled Cooling and Unloading

After the sintering phase is complete, the pressure is released, and the part is cooled in a controlled manner within the vacuum or an inert gas environment. Once at a safe temperature, the chamber is vented, and the densified part is removed.

The Core Components of a Vacuum Hot Press

The process is enabled by four critical systems working in unison. Understanding these components reveals how the precise control is achieved.

The Vacuum Chamber

This is the sealed enclosure that houses the entire process. It is designed to withstand both the internal vacuum and the external atmospheric pressure, creating the clean environment necessary for high-purity material processing.

The Heating System

This system provides the thermal energy for sintering. Resistance heating is common, but induction heating offers faster and more localized temperature control, which is often preferred for advanced materials.

The Press Mechanism

This hydraulic or mechanical system applies the compressive force. The design of this mechanism determines whether the pressure is applied in a single direction or uniformly from all sides.

The Control System

This is the brain of the operation. It integrates and precisely monitors the temperature, pressure, and vacuum levels throughout the cycle, ensuring the process parameters are strictly followed to achieve repeatable, high-quality results.

Understanding the Methodologies

Not all hot pressing is the same. The direction in which pressure is applied defines the two primary methods.

Uniaxial Hot Pressing

This is the most common method, where pressure is applied along a single axis, typically from the top and bottom. It is effective for producing simpler shapes like discs, blocks, and cylinders.

Isostatic Hot Pressing

In this method, pressure is applied uniformly from all directions, usually via a pressurized gas. This results in more uniform densification and is better suited for parts with more complex geometries. Hot Isostatic Pressing (HIP) is an advanced form of this technique, prized for its ability to produce components with nearly 100% density.

Key Advantages and Inherent Trade-offs

While powerful, vacuum hot pressing is a specialized technique with specific benefits and limitations.

Advantage: Superior Density and Minimized Porosity

The combination of heat and pressure is exceptionally effective at eliminating internal voids. This leads to materials with superior mechanical strength, hardness, and, in the case of ceramics, optical transparency.

Advantage: High Purity and Reduced Oxidation

The vacuum environment is the key differentiator. It protects reactive materials like refractory metals and certain ceramics from oxidizing or becoming contaminated at high temperatures, which would otherwise degrade their properties.

Trade-off: Process Complexity and Cost

Vacuum hot presses are sophisticated and expensive machines. The process requires precise control and longer cycle times compared to simpler methods like conventional sintering, making it a higher-cost operation.

Trade-off: Shape and Size Limitations

The need for a robust die to contain the material during pressing often limits the complexity and size of the parts that can be produced, particularly with the more common uniaxial method.

Making the Right Choice for Your Goal

Deciding whether to use vacuum hot pressing depends entirely on your material and performance requirements.

- If your primary focus is producing high-purity, ultra-dense components like transparent ceramics or refractory metals: Vacuum hot pressing is the ideal choice for its ability to prevent contamination and achieve near-total densification.

- If your primary focus is cost-effective production of metal parts without extreme density requirements: Simpler methods like conventional powder metallurgy sintering may be more appropriate.

- If your primary focus is achieving the absolute highest material integrity for mission-critical applications: Hot Isostatic Pressing (HIP) offers the most uniform densification, justifying its higher cost and complexity.

By understanding the unique interplay of heat, pressure, and vacuum, you can leverage this process to engineer materials that meet the most demanding specifications.

Summary Table:

| Process Stage | Key Action | Primary Outcome |

|---|---|---|

| Vacuum Evacuation | Remove air from chamber | Prevent oxidation and contamination |

| Controlled Heating | Heat to sintering temperature | Activate particle bonding |

| Pressure Application | Apply mechanical force | Eliminate porosity and densify material |

| Sintering & Cooling | Maintain parameters, then cool | Form solid, dense final component |

Ready to achieve ultra-dense, high-purity materials for your most demanding applications?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing capabilities to provide advanced high-temperature furnace solutions tailored to your unique needs. Our expertise in vacuum hot pressing technology, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities.

Whether you're working with refractory metals, advanced ceramics, or other specialized materials, our solutions deliver:

- Superior density and minimized porosity

- High purity with reduced oxidation

- Precise temperature and pressure control

Let us help you engineer materials that meet your most demanding specifications. Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum hot press and what is its primary function? Unlock Advanced Materials Processing

- What temperature control features do vacuum hot press furnaces have? Achieve Precision in High-Temp Material Processing

- How does vacuum hot pressing equipment enhance the matrix quality of diamond tools through improved wettability? Unlock Superior Diamond Retention

- How does the application of mechanical pressure contribute to the vacuum hot pressing formation of TiAl/Ti6Al4V? Expert Analysis

- Why is a laboratory vacuum system essential for the SPS of LaFeO3? Ensure Phase Purity and Tooling Longevity

- What industrial applications utilize vacuum hot press furnaces? Essential for Aerospace, Medical, and Electronics

- How does multi-station continuous vacuum hot pressing sintering equipment affect the production efficiency of diamond products? Boost Yields with Pipeline Sintering

- What core functions do high-purity graphite molds perform during the SPS of LaFeO3? Optimize Your Sintering Process