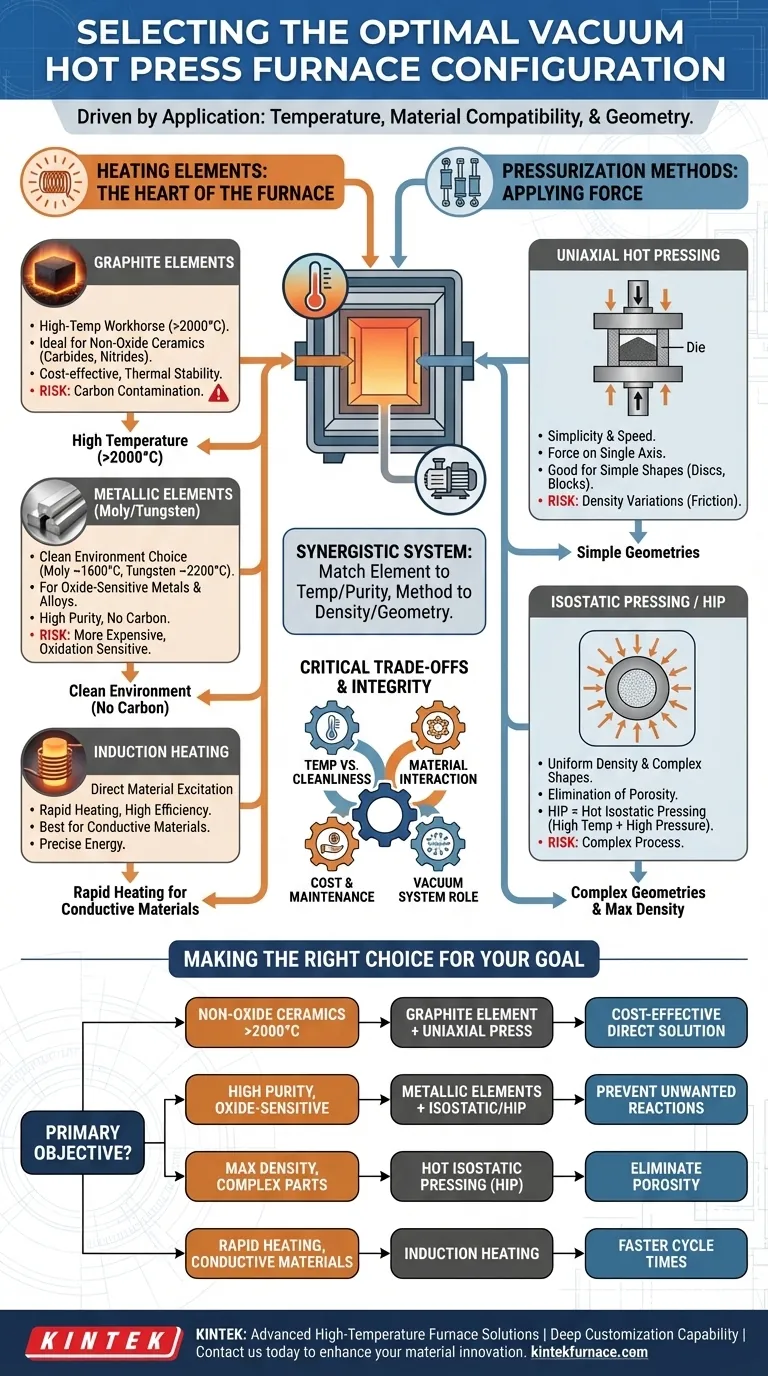

Selecting the right configuration for a vacuum hot press furnace is a critical decision driven by the physics and chemistry of your application. The choice of heating element and pressurization method hinges on two primary factors: the maximum operating temperature you require and the material compatibility within the furnace. For high-temperature (>2000°C) applications like non-oxide ceramics, graphite elements are standard, while metallic elements like molybdenum are used for cleaner, moderate-temperature environments where carbon contamination is unacceptable. Pressurization is chosen based on part geometry and density goals; uniaxial pressing is common for simple shapes, while isostatic pressing provides uniform density for complex components.

The optimal furnace configuration is not about finding the single "best" technology, but about creating a synergistic system. Your choice of heating element dictates the achievable temperature and atmospheric purity, while the pressurization method determines the final density and geometric complexity of your component.

Matching Heating Elements to Your Application

The heating element is the heart of the furnace. Its selection directly impacts the processing window available to you. In a vacuum, heat transfer occurs primarily through thermal radiation, meaning the element material and its placement are paramount.

Graphite Elements: The High-Temperature Workhorse

Graphite is the most common choice for very high-temperature applications, often capable of exceeding 2200°C. It offers excellent thermal stability and is relatively cost-effective.

These elements are ideal for sintering non-oxide materials like carbides and nitrides. Their primary drawback is the potential for carbon contamination from outgassing, which can react with the material being processed.

Metallic Elements (Molybdenum/Tungsten): The Clean Environment Choice

For applications demanding high purity and no carbon interaction, metallic elements are the solution. Molybdenum (up to ~1600°C) and tungsten (up to ~2200°C) provide exceptionally clean heating environments.

They are the standard for processing certain oxide-sensitive metals, alloys, and specific ceramics. These elements, however, are more expensive and must be protected from oxygen at high temperatures to prevent rapid degradation.

Induction Heating: Direct Material Excitation

Induction heating operates on a different principle. Instead of radiating heat from an element, it uses an electromagnetic coil to induce an electrical current directly within the conductive workpiece or a susceptor.

This method allows for extremely rapid heating rates and is highly efficient, as the energy is generated precisely where it's needed. It is best suited for processing electrically conductive materials.

Choosing the Right Pressurization Method

The goal of hot pressing is to apply force at elevated temperatures to accelerate densification. The way this force is applied has a major impact on the final part's properties.

Uniaxial Hot Pressing: For Simplicity and Speed

Uniaxial pressing applies force along a single axis, typically using a top and bottom ram to compress powder in a die. This is the simplest and most common form of hot pressing.

It is well-suited for producing parts with simple geometries, like discs or blocks. However, friction between the powder and the die walls can lead to slight density variations within the part.

Isostatic Pressing: For Uniform Density and Complex Shapes

Isostatic pressing applies pressure uniformly from all directions, typically using a high-pressure inert gas. This eliminates the density gradients seen in uniaxial pressing.

This method is ideal for creating parts with complex geometries or when achieving the highest possible uniform density is the primary goal. Hot Isostatic Pressing (HIP) combines this uniform pressure with high temperature in a single process, making it the gold standard for eliminating all residual porosity in critical components.

Understanding the Trade-offs and System Integrity

A vacuum hot press is a system where every component must work in harmony. A poor choice in one area can compromise the entire process.

Temperature vs. Cleanliness

This is the most fundamental trade-off. Graphite offers the highest temperatures but introduces carbon. Metallic elements offer ultimate cleanliness but have lower temperature limits and are less tolerant of poor vacuum conditions.

The Risk of Material Interaction

You must ensure chemical compatibility between the workpiece, the heating elements, and the furnace insulation at your target temperature. For example, using graphite elements to process a material that readily forms undesirable carbides is a critical process flaw.

Cost and Maintenance Considerations

Graphite elements are often less expensive to replace but can be brittle and require careful handling. Metallic elements are more durable but have a higher initial cost and can become brittle through recrystallization over time, requiring periodic replacement.

The Critical Role of the Vacuum System

An exceptional heating and pressing system is ineffective without a robust vacuum system. High pumping speed is necessary to quickly evacuate atmospheric contaminants and to manage any outgassing from the workpiece during heating, ensuring the process environment remains pure.

Making the Right Choice for Your Goal

To select the optimal system, align your primary processing objective with the corresponding technology.

- If your primary focus is processing non-oxide ceramics or carbides at very high temperatures (>2000°C): A graphite heating element with a uniaxial press is your most direct and cost-effective solution.

- If your primary focus is producing high-purity, oxide-sensitive metals or certain ceramics with zero carbon contamination: A furnace with metallic elements (molybdenum or tungsten) is the necessary choice to prevent unwanted reactions.

- If your primary focus is achieving maximum theoretical density and eliminating all internal porosity in complex parts: Hot Isostatic Pressing (HIP) is the superior method, often used to densify parts after initial forming.

- If your primary focus is rapid heating of conductive materials for faster cycle times: An induction heating system offers unparalleled speed by directly transferring energy to the workpiece.

By understanding these core principles, you can confidently specify a furnace system that serves as a precise tool for your material innovation.

Summary Table:

| Selection Factor | Heating Element Options | Pressurization Methods |

|---|---|---|

| High Temperature (>2000°C) | Graphite | Uniaxial Pressing |

| Clean Environment (No Carbon) | Molybdenum/Tungsten | Isostatic Pressing |

| Rapid Heating for Conductive Materials | Induction Heating | Hot Isostatic Pressing (HIP) |

Ready to optimize your vacuum hot press furnace configuration? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your material innovation with tailored solutions!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does precise temperature control affect Ti-6Al-4V microstructure? Master Titanium Hot Pressing Accuracy

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- What is the process of hot pressing? A Guide to Achieving Superior Material Density